Designers frequently ask how much gold plating they should specify on the connector pins. As I write this blog, (and yes, I’m old-fashioned and am actually typing it; I’m not using AI), the price of gold has increased about 28% in the last six months. So, the original question – how much gold should I use on my connectors – is extremely relevant. Gold Plating Is A Major Cost Driver The major costs in a connector set are: And on most connectors – well, most Samtec connectors … [Read more...]

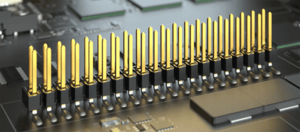

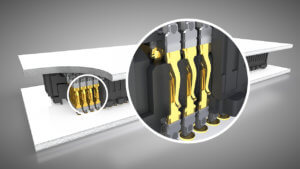

Manufacturing Variation: It’s Our Job To Find The Hidden Enemy

Manufacturing high-end electronics is difficult. Making a one-time sample for a demonstration or prototype can be challenging, but the real challenge is finding out how to make it consistently and in a profitable manner. That's what Aaron Tucker, Samtec's Director of Engineering - New Ventures (R&D), said during a recent presentation about the challenges of producing high-density, microminiature connectors. Most of his discussion focused on reducing manufacturing variability. I later … [Read more...]

Apollo Communication Hardware: A Fantastic Demonstration Of The Original Equipment

A working demonstration of the Apollo communication system -- the original Apollo S-Band communication hardware that was used in the Apollo moon missions in the 1960s and early 1970s -- was on display at DesignCon 2023. Marc Verdiell, CTO of the Samtec Optical Group, walks us through the setup. Marc is part of a team that is restoring this Apollo communication equipment to its original functional state. All equipment is on loan from private collections. The system operated at 2.1 GHz and … [Read more...]

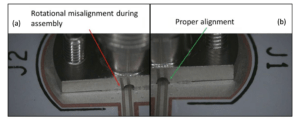

New Alignment Features Ensure Precision Alignment in Test & Measurement Applications

Samtec has developed an innovative, yet easy-to-use alignment technique for ensuring peak connector performance of precision, high-frequency compression mount connectors in test and measurement applications. The following explains the trend we were seeing and outlines the solution we developed to the common alignment challenge that was occurring. The Problem As data rates continue to push upward (224 Gbps PAM4) the need for precision, higher frequency compression mount test … [Read more...]

How Does Solder Reflow Affect RF Connectors?

Solder reflow plays an important role in the success and performance of high-bandwidth RF connectors. Sometimes, when a high-bandwidth RF connector is soldered together with an optimized PCB launch, the results can be unpredictable. It is important to investigate the root causes of solder reflow variation and analyze what techniques can deliver consistent performance across frequencies. In a new white paper from Samtec, “Impacts of Solder Reflow on High Bandwidth RF Connectors,” authors … [Read more...]

Practical Guidelines To Achieve Quality Connector Solder Joints: Part Two

This is the second in a series of three blog interviews with David Decker, the Manager of Samtec's Interconnect Processing Group (IPG). In these blogs, David answers some of the most frequently asked questions about achieving quality connector solder joints, as well as other connector-processing-related issues. BTW, here's the link to the first blog, and here's a link to the third one. Our goal is to provide short answers that address the main issue of the question. If you want more … [Read more...]

More Connector Plating FAQs: Underplating, Base Metals, Lubrication, Voltage

Once upon a time, in a blog a long, long time ago, in a galaxy far, far away, a wise connector guru said "Plating affects the life and quality of the connector system, including corrosion resistance, conductivity, solderability, and of course, cost." Actually, it wasn't that long ago; it was in a blog we posted last month. And it was written in Indiana, which does seem to be far away from everywhere. Finally, it wasn't a wise connector guru. Rather, it was written by me, although I was quoting … [Read more...]

Free Wideband RF Launches White Paper

Samtec recently published a major white paper, “Wideband RF Launches: Much More Than Footprints On PCBs.” This white paper shows that very wide bandwidth RF launches are possible to implement in PCBs, even with vias included. This does not mean it is a trivial task. Competing requirements, be they electrical, mechanical, manufacturing, or cost, must be considered and balanced simultaneously. This white paper -- a link to it is at the end of this blog -- elaborates on some of … [Read more...]

Practical Guidelines To Achieve Quality Connector Solder Joints: Part One

Many factors affect the quality and performance of a connector: pin material, the quality of the stamping, the quality of and choice of surface finish, and the tolerances on the plastic insulator, just to name a few. Beyond the connector, another factor that is crucial to the performance of the connector on the printed circuit board is the quality of the solder joints. This is the first in a series of three blogs, which are interviews with David Decker, the Manager of Samtec … [Read more...]

Connector Plating FAQs: Normal Force, Cycles, Temperature, and Other Essentials

Plating affects the life and quality of the connector system, including corrosion resistance, conductivity, solderability, and of course, cost. This is part two of a discussion with Phil Eckert, Samtec’s Quality Engineering Manager, and Matt Brown, Principal Engineer, about all things pertaining to connector plating. Here’s a link to part one. These blogs, and the upcoming ones in this series, answer connector plating questions that Samtec Quality and Processing experts are frequently asked. … [Read more...]