Collins Aerospace recently published a white paper entitled “Qualification Of High Density Connector Solutions For Military and Avionic Environments.” It discusses their qualification process of high density connectors for rugged military and avionics applications. This paper focuses on the thermal testing of solder joints because “printed circuit board (PCB) assemblies are made up of many different materials that have different coefficient of thermal expansion (CTE) … [Read more...]

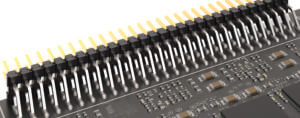

The Fine Art of Contact Plating

In the first article of this series, we looked at how contacts are formed. This time, we'll investigate the next step in the manufacturing process - plating. Have you ever looked closely at an electrical contact? Contacts may be small and hard to see, but they are the most important component in any connector. With their intricate design and shiny gold plating, they have as much in common with fine art as they do with electronic components. But connector manufacturers do not invest huge … [Read more...]

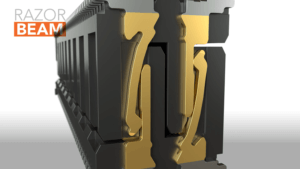

Do You Care About Your Connector Contacts?

Have you ever wondered how the contacts get into a connector? Quite possibly not as they tend to be small and hidden, but the contact is at the very heart of connector design. This article is the first of a short series that looks at the life of a contact, from manufacturing to understanding its performance. Hopefully, by the end, you will have a better understanding of what the contact does and how it does it. At the simplest level, a connector is a device that allows the joining of an … [Read more...]

Solder 0.15 mm Coplanarity Connectors With a 0.10 mm Stencil

COPLANARITY AND STENCIL THICKNESS STUDY Samtec and Phoenix Contact recently completed dual studies that show when PCB processing requirements dictate using a 0.10 mm (.004”) stencil, the coplanarity requirements for most connectors can be relaxed to a maximum of 0.15 mm (.006”). In other words, Samtec and Phoenix Contact both successfully soldered PCB connectors with 0.15 mm coplanarity using a 0.10 mm thickness stencil with optimized apertures. CHALLENGE FOR DESIGNERS Designers … [Read more...]