Samtec has provided Final Inch designs for years at no cost. Final Inch is a reference design report for a PCB launch, or break-out-region (BOR), for one of our connectors. Obviously the BOR/launch must be carefully designed to allow for the best possible high-frequency performance.

As we introduce new precision RF interconnects we continue to push the limits on mmWave test boards and the design of our RF Launches. I recently spoke with Kelly Garrison, Samtec’s Principal RF Engineer, about our progress …

Danny: What is driving this? Why are we developing these new mmWave boards and RF launches?

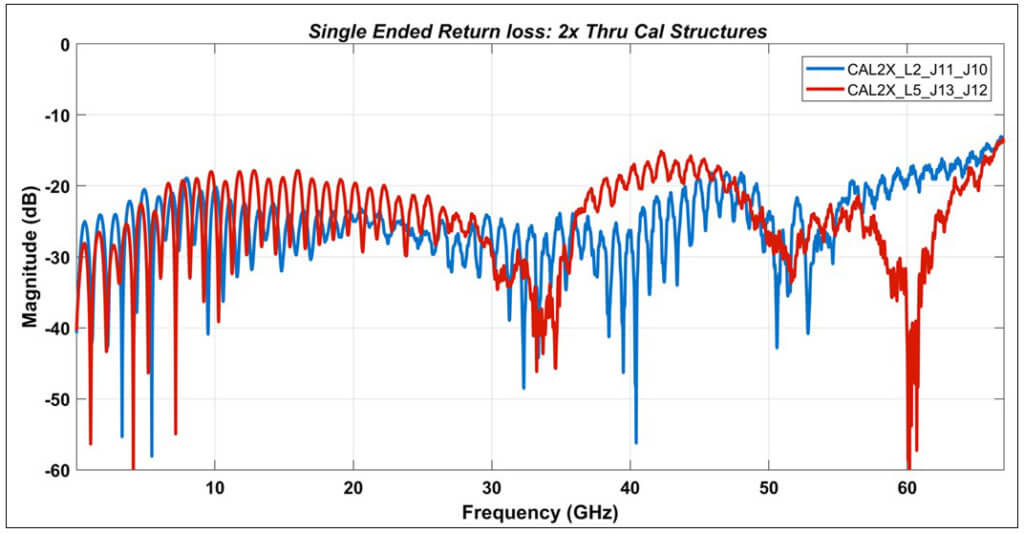

Kelly Garrison: We’ve been pushing higher in frequency as we move into the RF market, from 2.92mm connectors at 40GHz to 1.85mm and SMPM at 67 GHz and now to 1.00mm at 110 GHz. Each step up potentially opens up a new market for us, from millimeter wave 5G at 50+GHz to automotive radar applications at 70+GHz. Providing board launch details for those connector families helps our RF customers with their designs and allows us to demonstrate our expertise. Along the way, we also improve our ability to test our own high speed digital products, since we break those products out to an appropriate RF connector on our test boards.

Danny: What are some of the challenges we faced?

Kelly: Moving higher in frequency brings along some familiar signal integrity challenges and a few new ones. Every time we move higher in frequency, the parasitic capacitances and inductances that show up with every launch get worse and more care and attention must be paid in simulation time to managing them. That’s sometimes as simple as scaling the size of all the features in your design, but often we hit limits as to how far things can shrink and a creative solution becomes necessary. And new challenges like trace radiation, waveguide modes, and weave effects have to be considered going into a design so they can be accurately modeled and not surprise us later.

Danny: What have we learned along the way?

Kelly: We’ve learned some valuable lessons. One is that when starting a new connector design, the launch has to be considered at the beginning. The interface between a coaxial connector and a board is not a gentle interface, and that’s even before you get to the rest of the launch design! The abrupt transition between an air dielectric and a printed circuit substrate can create problems that you can’t fix with a board design later, they have to be mitigated at the start.

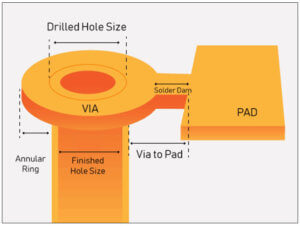

Second, now that the signal is on the board, getting it broken out onto a clean transmission line is the rest of the game, especially when the signal has to change layers with a via. We spend the largest amount of our time in launch design dealing with vias. The industry provides a wide array of via options to a designer and having a good relationship with your board vendors is critical here. You may have to try something new and they’re the ones who have to build it!

Finally, an RF launch is going to look different. Ground vias will be small and tightly packed. The signal via might have a page of notes in the drawing. The board materials will be unfamiliar. That’s to be expected when pushing limits.

Danny: How does all of this help our customers?

Kelly: All of the things we learn when we design our test boards, we pass along to our customers. That can be anything from a suggested PCB footprint on a connector print, to our Final Inch documentation on our test board design, to a custom launch for a customer’s stackup.

Danny: Kelly, if somebody is interested in learning more about an RF launch, mmWave boards, testing, etc., who should they contact?

Kelly: They can contact the RF Technical Group.

Danny: Thanks, and let me take this time to put in a quick word about the Signal Integrity Group. The Signal Integrity Group (SIG) and Teraspeed Consulting are Samtec Technology Centers that provide signal integrity expertise at both the component and full system level.

The Signal Integrity Group (SIG) provides in-house signal integrity expertise for complex applications, with live EE support available 24/7 worldwide. Services include full-channel analysis, high-data rate simulations, application-specific design and development assistance, and advanced design support.

Samtec Teraspeed Consulting offers Tier 1 level signal integrity expertise and capabilities delivered directly to your engineering team. This includes complete system design, full channel signal and power integrity analysis and modeling, thermal management, in-depth signal integrity training, and signal integrity optimized advanced IC packaging for 112 Gbps PAM4 and beyond.

Other Links That May Be Of Interest:

Leave a Reply