In the manufacturing world there are standards for just about everything, and they all are typically there to ensure a product can perform as expected for the end application. Among these standards is IPC-A-610 covering solder joints for varying types of connector termination styles.

For this blog, we are going to take a quick look at IPC-A-610 Class 2 and Class 3 solder joints, and some of the requirements of those two classifications. To narrow the focus further, we are looking at a J-Lead solder joint exclusively.

What is IPC-A-610?

IPC-A-610 covers the “Acceptability of Electronic Assemblies,” and more specifically for this blog we will look at the requirements for J-Lead solder connections. Since varying applications have different requirements, IPC has different classes and what a solder joints must look like to meet those class requirements.

Class 2 (J-Lead Components)

IPC-A-610 Class 2 is typically what is required of Samtec’s products. For Class 2, a product will have a need for extended reliability, but is not essential for the product. We cover a few of the requirements below, but not all of them.

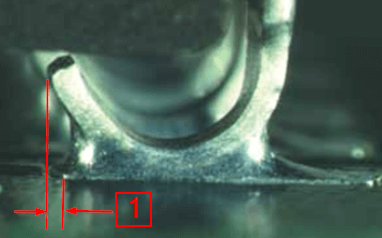

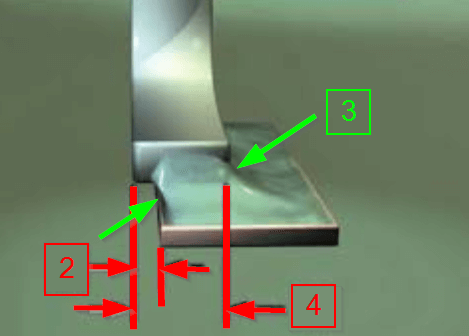

Class 2 affords the manufacturer a larger degree of imperfection in the assembly; such as pad offset or overhang for the toe (1) and the side (2), and a thinner end joint width (3).

For side overhang, Class 2 states that the component lead may overhang the side of the pad (2), a maximum of 50% the width of the lead.

The end joint width (3) is the width of the solder joint at the most narrow point and must be a minimum of 50% of the lead width (4).

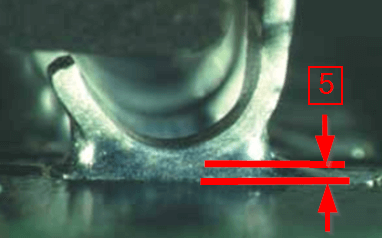

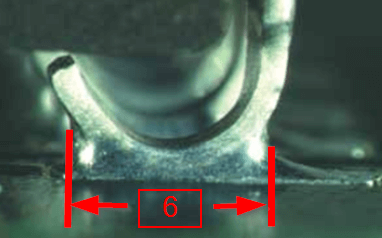

The solder thickness (5) between the lead and the pad landing is not specified, but a properly wetted fillet must be present. The side joint length (6) of the solder joint, at the narrowest point, must be at least 150% the width of the lead (4).

Class 3 (J-Lead Components)

Many of Samtec’s products can meet IPC-A-610 Class 3 which is normally required when a product must have continued high performance in extreme / harsh conditions. Mil / Aero and Medical applications typically require Class 3 products.

Class 3 increases the requirements in most areas of inspection for the solder joint over Class 2. The solder thickness (5) requirement remains “not specified,” and the side joint length (6) are the same as Class 2, but many of the other specifications have increased requirements.

For instance, the side overhang (2) and end joint width (3), are tightened in both directions by 25%. The side overhang is lowered to a 25% maximum of the width of the lead (4), and end joint thickness (3) is increased to a minimum of 75% of the lead width (4). While this may not seem to be a huge increase, it does add to the difficulty of producing a conforming product.

Here’s a subsequent article on “Understanding IPC Class 2 vs Class 3 For A Gullwing Lead.”

How can Samtec Help?

If you made it this far, then clearly you are interested in the topic, and want some additional information. Here at Samtec we are always focused on ways to be a service leader in this industry, and assisting customers with processing questions is no different. Have a question about a Samtec product, and which class it would meet in IPC-A-610? We are here to help answer that question. Please email [email protected].

You can also check out the Processing Documentation and Support page for a wide range of information including help with reflow solder, wave soldering, solder locks, cleaning, and more.

Other Links that May be of Interest

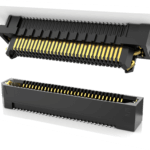

The HSEC8 uses the J-Lead contact style. Below are a couple of links that you might find helpful.

- HSEC8 Product Pages

- HSEC8-DV Rework Guidelines

Nice quick review.

Hello Murat,

Thank you for the comment.

-Brian

It’s great information. Thanks for explaining the difference between both the classes.

Hey Betty,

Thanks for comment.

-Brian

Great information

Thanks for explaining Brian.

Jim Roberts

Great info, Thanks for taking the time to put this out.