IPC-A-610 covers a wide range of solder joints, and what it takes to meet Classes 1 – 3 in varying types of connector termination styles. These classifications help a designer determine if a connector is capable of being used in their application.

In a previous blog, I discussed IPC Class 2 vs Class 3 solder joints for J-Lead Components, and in this one we will look at the difference for Gull Wing Leads. In case you were wondering, a gull wing lead is a type of surface mount lead that is bent in a configuration similar to a seagull’s wing.

What are the Specifications for Class 2 vs Class 3 Solder Joints?

IPC-A-610 is used to inspect and classify the “Acceptability of Electronic Assemblies.” As previously mentioned, we will be exploring the requirements for Class 2 and Class 3 solder joints in a Gull Wing Lead. We will not be discussing Class 1 since it is focused more towards a consumer product where all that matters is functionality, and extended life isn’t the focus.

It should be noted, this is a small example of what is covered by Class 2 and Class 3, and is meant to give you an idea of how they vary.

Class 2 (Gull Wing Leads)

A majority of Samtec’s products will fall under the IPC-A-610 Class 2 umbrella. Class 2 is typically focused on a commercial type of product where continued performance and extended life is required, and an uninterrupted service of the product is desired but not mission critical. The normal environment (temperature and contamination) for this end user is not considered extreme.

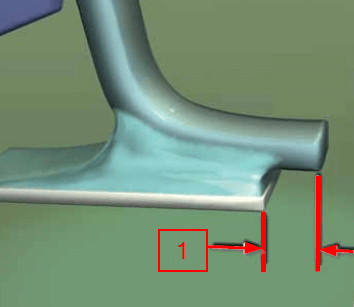

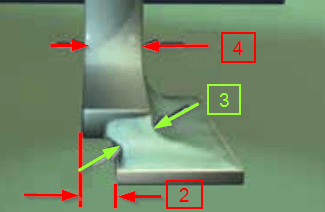

Because Class 2 provides the manufacturer a larger degree of imperfection in the solder joint, it is easier to manufacture at this level and often cheaper to produce. An example of this is the “pad offset” or the overhang of the contact from the pad. The Toe Overhang is shown in (1), and is acceptable as long as it does not violate electrical clearance. This also means there is no requirement for a Toe Filet. The Side Overhang is shown in (2), and Joint Width is also measured and is shown in (3).

Side Overhang (2), for Class 2, states a component lead may overhang the side of the land (contact pad) with a maximum of 50% the lead width(4), or 0.02 in. (0.5 mm), whichever is less.

End Joint Width (3) is the width of the solder joint at the most narrow point. This width must be a minimum of 50% the width of the lead (4) .

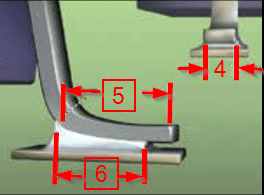

Side Joint Length (6) for a “long foot,” or a Lead Foot Length (5) that is equal to or greater than three lead widths (4), the Side Joint Length (6) must be a minimum of 3 (4) or 75% of (5); which ever is the longer of the two.

Class 3 (Gull Wing Leads)

IPC-A-610 Class 3 takes the requirements found in Class 2 and raises them. A Class 3 solder joint requirement is typically found in products that require continued high performance in extreme / harsh conditions. Medical, Space, and Mil / Aero applications typically require Class 3 products.

Some requirements are similar in Class 2 and Class 3; such as the Solder Joint Length (6) and Toe Overhang (1). However, many of requirements are significantly more difficult to meet in a Class 3 solder joint.

End Joint Width (3) and Side Overhang (2), are both required to meet a more stringent specification. The End Joint (3) must be at least 75% of the lead width (4), and the Side Overhang (2) only affords the lead width (4) a maximum 25% of the lead width (4) or 0.02 in. (0.5 mm), whichever is less of overhang on the side of land.

Samtec is Here to Help

As part of Samtec’s focus for being a leader in service, we are here to assist with any processing questions or issues that you might have. If you need additional information about Samtec’s products, or if those products will meet a specific class in IPC-A-610 we can assist.

Please email [email protected] with any processing questions you may have.

You can also use the online resources by checking out the Processing Documentation and Support page that has a significant amount of information on solder reflow, wave soldering, solder locks, and more.

Leave a Reply