Commercial Off-the-Shelf (COTS) products are making their way into industries that wouldn’t have considered them previously. This is mainly due to the flexibility, speed of delivery, and cost savings that COTS products offer when compared to a full MIL-SPEC product.

However, this doesn’t mean that the Military / Aerospace, Space, Industrial, Transportation, Automotive, and Medical industries do not need to know the performance of a COTS product in their application. Knowing the outgassing performance of a product is often as important as knowing other mechanical and electrical specs if it is used in those applications.

What is Outgassing?

Outgassing is the process in which a non-metallic material such as a polymer, adhesive, rubber, or potting compound / epoxy will release a gas when exposed to heat and or a vacuum. This gas will eventually condense on other materials, and could render them inoperable.

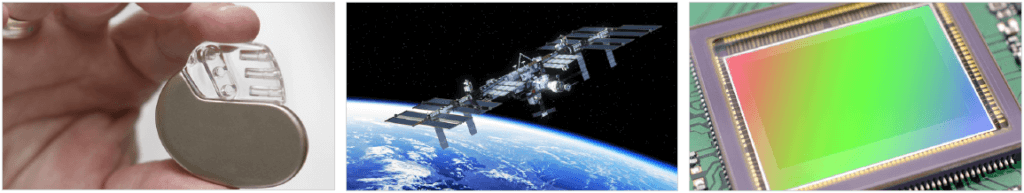

The outgassing performance of a material is vitally important in areas with sensitive electronics, lenses (optics), mirrors, and windows to prevent damage of those items. A great example of this, would be anything used in the International Space Station, anything implanted in the body or used in hospitals to prevent contamination, or components used with image sensors.

While third party testing does exist for outgassing, Samtec currently utilizes the data published by NASA to determine if a series is considered to be a low outgassing product, and can be used where the outgassing of a product can be an issue.

How is it Tested?

NASA uses the test ASTM E595-77/84/90 to determine a material’s performance when exposed to an environment of high heat and or extreme vacuum. The steps to this test include:

- Exposure of the parts to 25°C at a 50% Relative Humidity for 24 hours

- Products are then weighed

- Exposure in a chamber at 125°C for 24 hours at a vacuum no less than 5×10-5 torr

- Chamber contains a cooling collector plat at 25°C to collect gas condensate

- Products are then weighed again with the collector plate

The weight of the sample is taken before and after the experiment and the materials are considered to have passed if the total mass lost (TML) and the collected volatile condensible materials (CVCM) are below 1.0% and 0.10% respectively.

Samtec recently released its Outgassing FAQs Guide as supporting material for Severe Environment Testing (SET) page. SET is just another way that Samtec is providing customers with needed performance information by testing several product series beyond the typical industry standards and specifications.

If you have additional questions concerning outgassing, please contact [email protected].

Samtec is a leader in modified COTS parts, and offers many non-standard part options such as plating in Tin-Lead and up to 50µin Gold plating. For more information on modified COTS solutions, please contact [email protected].

[…] said, the evaporation process (known as outgassing) takes a while – 24 hours typically – and the solvent can have a punishing effect on the […]