In the first part of this series on Severe Environment Testing (SET) we covered Electrostatic Discharge (ESD) and Dielectric Withstanding Voltage (DWV) at an altitude of 70,000 ft.

Continuing on the path of “how” we tested, we will be looking at the other tests that were introduced for SET; Mating / Unmating / Durability (100% Relative Humidity, 250 cycles), Temperature Cycling (500 cycles), and Mechanical Shock for LLCR and Event Detection.

If you haven’t read the first two blogs about SET then make sure to read “Severe Environment Testing for Connectors” for the “why,” and “A Deep Dive Into Severe Environment Testing (Part I)” for the “how.”

What is different with these tests?

The tests that we are discussing are part of the normal Samtec qualification testing, but with an added twist to the test.

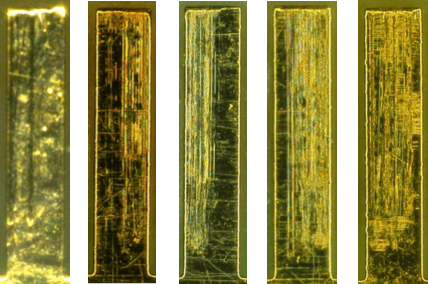

Mating / Unmating / Durability (100% Relative Humidity, 250 Cycles)

The overall goal for Mating / Unmating / Durability is to show the capability of the product to perform even when being subjected to cycling and environmental factors during regular use.

Normal humidity testing is performed at a Relative Humidity (RH) at 90% to 98% for 10 days with 25 cycles where the SET version of the test uses 100% RH and 250 cycles.

Mechanical Shock / Random Vibration / LLCR and Event Detection

The overall goal for Mechanical Shock / Random Vibration / LLCR and Event Detection is to measure the ability of a product to withstand a series of mechanical shocks and random vibrations.

The standard mechanical shock and vibration test uses 100G Peak shock for 6 milliseconds, Half Sine where the SET version of this test uses 40G Peak shock for 11 milliseconds, Half Sine.

The standard random vibration test uses 7.56 gRMS for 2 hours per axis vs the SET version of this test using 12 gRMS, 5 – 2000Hz for 1 hour per axis.

Temperature Cycling

The overall goal for Temperature Cycling is to test the ability of the product being tested to withstand extreme temperature changes.

The standard temperature cycling test will take a connector set from -55°C to +85°C 100 times with a half hour dwell at each temperature. The SET version of temperature cycling will take the connectors from -65°C to +125°C 500 times with a half hour dwell at each temperature.

What is next?

Samtec is always listening to its customer base, and what information they are seeking. As previously stated, Samtec is at the beginning of rolling out these test results; however, there are plenty of product series in the works. The first two we have completed are the SEAM / SEAF and the TFM / SFM.

Make sure to check out the test reports on the series pages of www.samtec.com or by clicking the links above. For more information about SET, please contact [email protected].

Leave a Reply