In the last blog on Severe Environment Testing (SET), we covered “why” and “what” Samtec was testing on its connectors. In this one, we are going to look a little bit further into the “how.”

Electrostatic Discharge and Dielectric Withstanding Voltage at an altitude of 70,000 ft will be discussed as part of two new tests being performed under Severe Environment Testing.

What is new?

Electrostatic Discharge

Typically, with connectors Electrostatic Discharge (ESD) is not tested. However, in severe environments, system designers need to know how the components will withstand ESD.

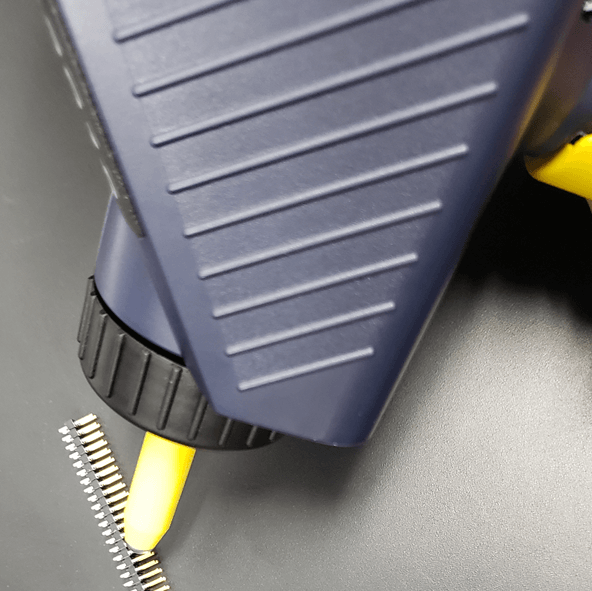

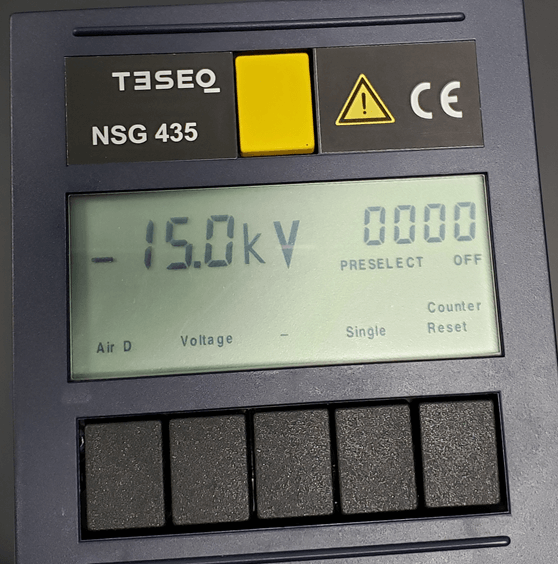

For this test, Samtec utilized EN61000-4-2 from VITA 47. The connector is tested mated and unmated, and inspected both before and after the shock to determine if any damage occurred.

More specifically, the ESD events range from 0 to 15 kV as discharged through a 150 – pf capacitor though a 330-ohm resistor. For SET, Samtec chose to expose the connectors to 5, 10, and 15 kV (10 times), and inspected the parts after each test. If physical damage is not visually detected, then the parts have passed the test.

Perhaps you are curious as to why the pass/fail is a physical inspection as opposed to an electrical confirmation. By nature, connectors are passive devices (no active components), and the only damage that could occur would be to the plating.

Dielectric Withstanding Voltage at Altitude

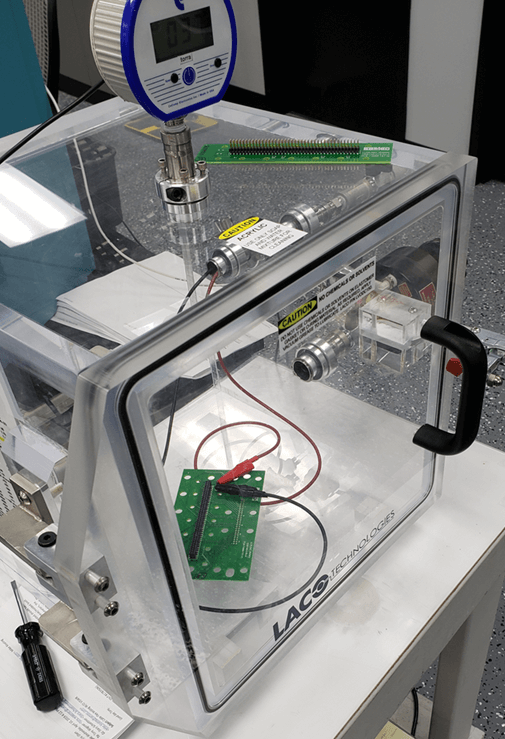

Dielectric Withstanding Voltage (DWV) testing isn’t new to Samtec nor this blog, but testing DWV at an altitude of 70,000 ft is new.

Since the over all test setup for DWV was covered in a previous blog, we aren’t going to cover it here, however, it should be noted that the test voltage used was 300 V.

The same pass/fail conditions are still in place for the connector sets, and are detected by the same equipment as the standard DWV test.

Non-Operating Class Temperature

It is important to know the limits of a product, but it is also important to know at what temperature range a product can operate at peak levels. For Non-Operating Class Temperature testing, the product is Low Level Contact Resistance (LLCR) tested, exposed to -55°C to 105°C for 100 cycles, then tested for LLCR again, exposed to -65°C to 125°C for 100 cycles, and finally tested for LLCR again.

Assuming the product maintains a delta of <= 5 mΩ for LLCR from the start of the test to the end, it is considered to be a stable product for those temperature ranges.

Samtec publishes all of its reports on www.samtec.com and can be found according to the series pages.

If you are interested in learning more about SET then make sure to check out test report for our SEMA/SEAF connector set here.

Leave a Reply