Gas tight testing falls into the qualification testing that Samtec performs on all products prior to their release. It is not a one and done test, and it uses some of the tests that we have previously discussed as part of the test sequence.

As you would probably guess, this test uses a gas to expose any inefficiencies in the system being tested, and the methods behind that will be explored in this blog.

What is Gas Tight Testing?

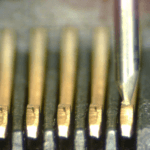

Gas tight testing isn’t an island all to itself, and is actually testing if the normal force of a connector set can maintain a gas tight seal. If the connector set does not have a gas tight seal (a high enough normal force), the test will expose this through the use of a nitric acid vapor.

Through the use of nitric acid, the test is accelerated, and simulates a corrosion over time. This is similar to what a connector set it exposed to in harsh environmental conditions. Exposure can cause an oxidation of the metal in the connectors and impact the electrical performance.

How is it Tested?

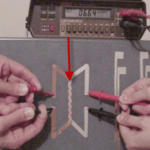

A connector set is first soldered to a Low Level Circuit Resistance (LLCR) test board. The initial LLCR reading is taken for the connector set that serves as a base line of performance.

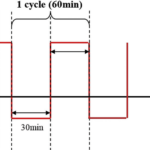

The nitric acid vapor is allowed to saturate the atmosphere of the test chamber before the parts are placed into it for an hour. LLCR is then performed again on the parts to see if any oxide or film development degraded the electrical performance of the connector set.

If the normal force of the connector set was not high enough, the second pass of the LLCR test will show a dramatic difference in performance, and the connector set will have failed gas tight testing.

Samtec tests its products according to EIA-364-36A “Test Procedure for Determination of Gas-Tight Characteristics for Electrical Connectors, Sockets and/or Contact Systems.”

To see the qualification test report that includes Gas Tight Testing results for the SEAM/SEAF series please click here, or type in the series name of the part you are interested in on www.samtec.com.

[…] that the gas connections are tight. You should ensure every connector is tight before using the system. When they are tight, it will […]