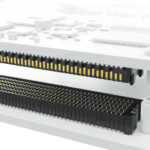

Samtec performs several tests in-house as part of our qualification testing on a product series; including Low Level Contact Resistance (LLCR). It measures the amount of resistance in a position on a part.

LLCR is used in combination with several other tests to track the overall performance of a part under specific conditions, and is the test we will be discussing today.

What is Low Level Contact Resistance (LLCR)?

LLCR is used to measure the electrical resistance of a system under test with an open circuit voltage. The voltage is low enough not to disrupt thin films that may exist in the contact interface. The current level is also low enough to ensure not to heat the device under test and melt asperities. In other words, the current is low enough that oxide layers will not be destroyed and skew results.

LLCR is measured in mOhms (mΩ) and a normal LLCR reading is 5-15 mΩ for a board to board system. For the test, the voltage is limited to 20 mV and current is limited to 100mA. A delta of R > 15 mOhms is typically considered a failure.

Samtec uses the EIA-364-23 “Low Level Contact Resistance Test Procedure For Electrical Connectors and Sockets” standard for the LLCR testing setup.

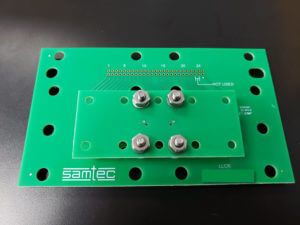

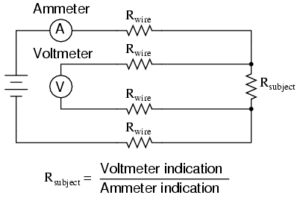

During any test, it is important to consider your test system, equipment, and boards to determine how they will affect the test results. The four-wire method is used to ensure only the resistance in the common trace between the connectors is measured. A schematic of this is shown above.

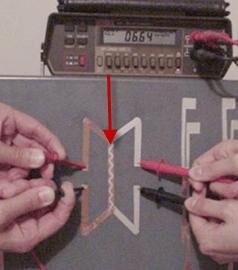

A simplified four-wire method is displayed in the picture to the right. As the current is passed through the silver loop (right side), the voltage drop is measured through the copper loop (left side).

In this picture, the common trace is the trace with the red arrow pointing to it. A similar setup is used on the PCB’s for testing LLCR on Samtec’s parts.

Where is it used?

Because of the sensitivity to changes that LLCR presents during testing, it is the best form of evaluating the contact interface and can show early onset problems in the system.

LLCR is used to assess a connector’s performance during Gas Tight, Thermal Age, Durability, Shock/Vibe, and Extended Life testing.

Samtec publishes all of its reports on www.samtec.com and can be found according to the series pages. To see the qualification test report that includes LLCR test results for the SEAM/SEAF series please click here, or type in the series name of the part you are interested in on samtec.com.