Thermal Shock testing isn’t unique to the connector world, but it does play a big role in the qualification testing that Samtec puts all connectors through before they are released for production.

Chances are likely that you thermally shock many items per day and don’t give it a second thought unless they break. Some examples of this would be placing a glass cup previously containing ice into a sink full of hot water or rinsing your freshly used frying pan with cold water.

Thermal shock places stress onto the items we use, and need to know that they can withstand it.

What is Thermal Shock Testing?

Thermal Shock is used to test the ability of a connector to withstand extreme temperature changes simulating the worst possible conditions of storage, use, and transportation. This test is also known as “temperature cycling.”

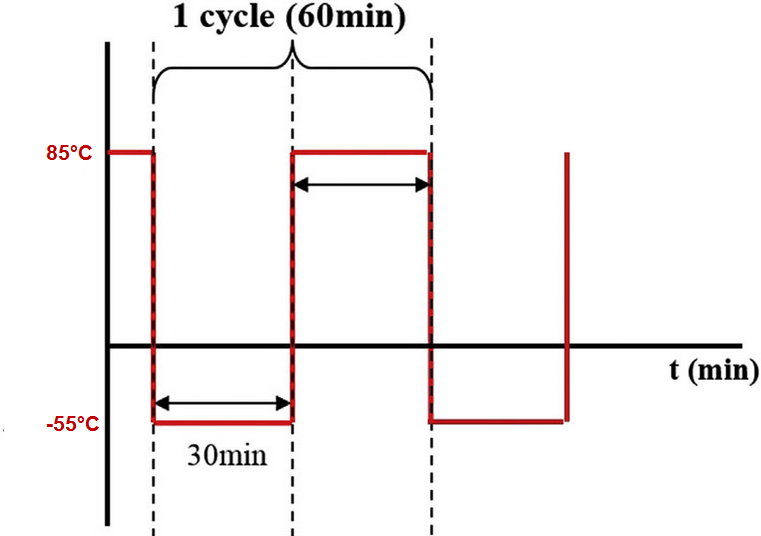

The test exposes the connectors to extreme high and low temperatures of -55°C to +85°C. The temperature change will cycle 100 times throughout the test with a 1/2 hour dwell at each level.

In order to determine if the product passed the test, we will test and measure the Low Level Circuit Resistance (LLCR) and Insulation Resistance / Dielectric Withstanding Voltage (IR/DWV) before and after thermal shock. If you are not familiar with these tests, then make sure to check out the blog links above.

Samtec tests its products according to EIA-364-32 “Thermal Shock (Temperature Cycling) Test Procedure for Electrical Connectors and Sockets.”

Why Test Thermal Shock?

Just like with the other tests that are part of qualification testing, thermal shock testing is designed to ensure a connector can withstand varying conditions that it might be exposed to in the field.

Samtec knows that its products are used in many different applications and conditions. Knowing the parts can withstand thermal shock affords the customer with confidence that the connector set will perform as expected.

Samtec publishes all of its reports on www.samtec.com and can be found according to the series pages. To see the qualification test report that includes thermal shock test results for the SEAM/SEAF series please click here, or type in the series name of the part you are interested in on samtec.com.