In the video above, it might not appear that much is taking place, but just like with transformers there is “more than meets the eye.” Alright, that was corny, and I am mildly ashamed, but Nanosecond Event Detection for shock and vibration is nothing to be ashamed of testing.

Maybe your system operates within highly dynamic environment, and it is important that you don’t experience any interruption in your signal. This is where Nanosecond Event Detection comes into play.

What Does This Test Measure?

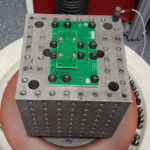

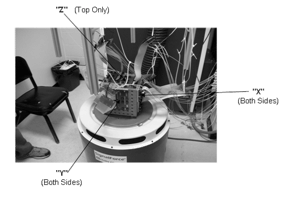

Nanosecond Event Detection consists of using a mated pair of connectors soldered onto a test board. There are a series of cables also soldered to the test board that monitor continuity; see the video above for a visual. It should be noted that event detection cannot measure the length of an event, and will only note its occurrence.

The test is designed to measure the ability of the connector set to withstand a series of mechanical shocks and random vibration in all three axis of the product.

Any system that will experience rough handling, transportation, or will operate in conditions where the system will be exposed to shock should be tested to ensure the product will continually perform.

Nanosecond event detection is conducted according to EIA-364-87 “Nanosecond Event Detection Test Procedure for Electrical Connectors, Contacts and Sockets.” This standard calls for the test to be performed for 50 nanoseconds at 10 ohms.

For mechanical shock, standard EIA-364-27 “Mechanical Shock (Specified Pulse) Test Procedure for Electrical Connectors and Sockets” is used. The standard calls for 100 G Peak, 6 milliseconds, half-sine. This is performed 3 times per direction and axis.

To test the connectors for their ability to withstand vibration, Samtec uses EIA-364-28 “Vibration Test Procedure for Electrical Connectors and Sockets.” The standard calls for 7.65 gRMS random vibration for 2 hours/axis.

How is This Test Different Than Mechanical Shock and Vibration Testing using LLCR?

While both tests are similar, they provide a different information set. Nanosecond event detection is used to actively monitor for disruptions in the signal, and the connector set is powered for this test

LLCR based detection will only tell you if your system functioned before and after the event, and the connector set is unpowered as it is not being actively monitored.

In case you missed the blog on Mechanical Shock and Vibration you can check it out here.

Samtec publishes all of its reports on www.samtec.com and can be found according to the series pages.

To see the qualification test report that includes Nanosecond Event Detection test results for the SEAM/SEAF series please click here, or type in the series name of the part you are interested in on www.samtec.com.