It was hot, really hot. In fact, things were getting so bad the walls around us were starting to melt, and just like that it was over; we failed current carrying capacity.

That is Current Carrying Capacity (CCC) in a nutshell, well it would be if the parts were failing. Samtec performs this in-house during the qualification testing for all product series.

What is Current Carrying Capacity?

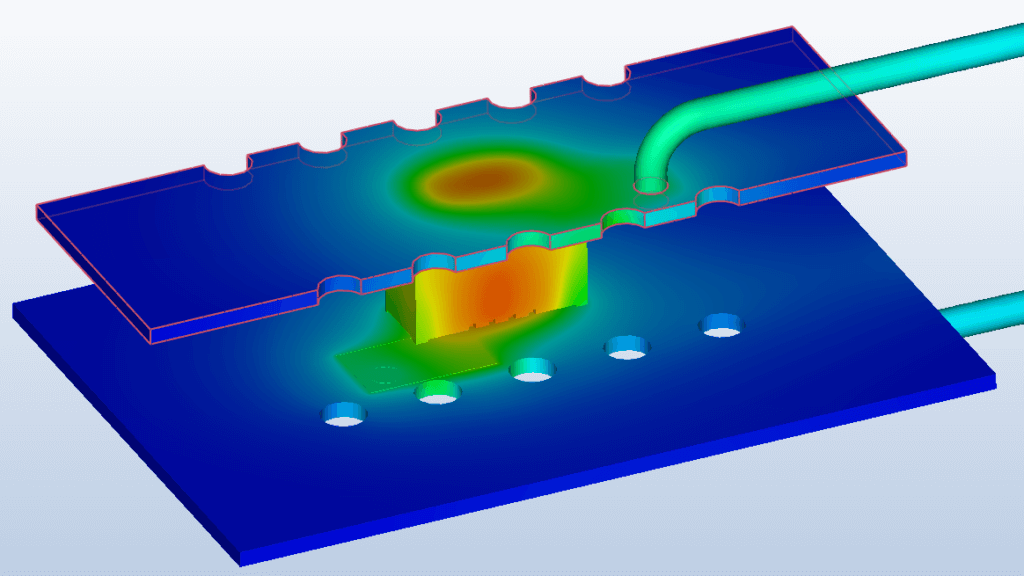

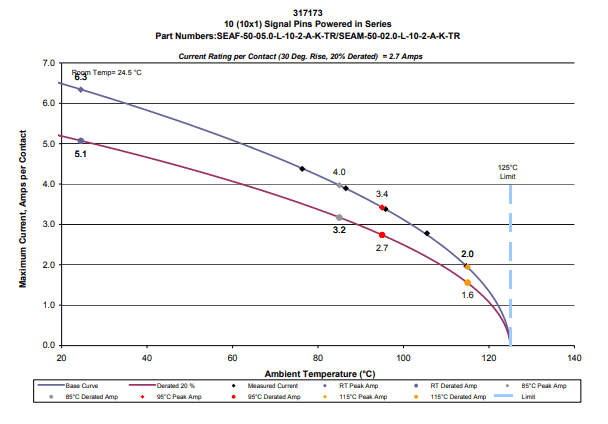

Current Carrying Capacity (CCC) is used to establish the maximum current carrying capacity versus ambient temperature in a connector set without exceeding the temperature limitations of the materials.

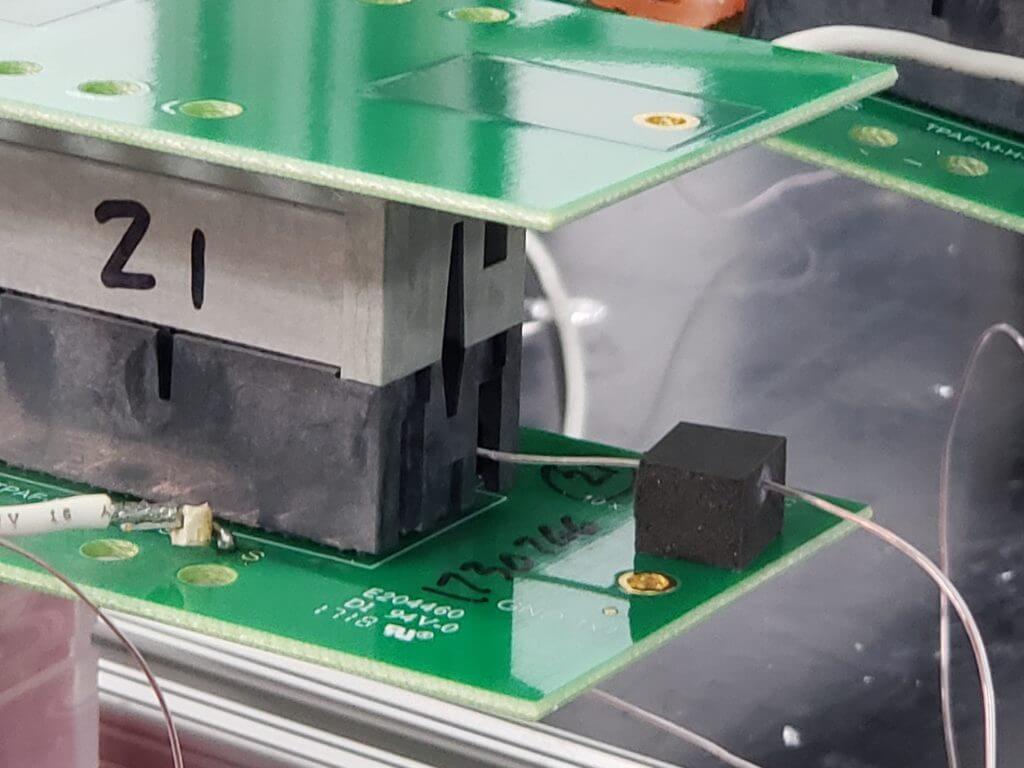

When current passes through the contact, the temperature increases as a result of I2R (resistive) heating. This test aims to get the product to rise 30°C over five step increments in current. The current it takes to achieve this temperature rise is then de-rated by 20%. The test is conducted in a closed environment, and thermal couples are placed on the connector set to measure the temperature rise.

An example of the CCC setup includes different power configurations by powering contacts as follows:

– Single Row: 1×1, 1×2, 1×3, 1×4, and all contacts powered

– Double Row: 2×1, 2×2, 2×3, 2×4, and all contacts powered

Samtec tests CCC according to EIA-364-70 “Temperature Rise Verses Current Test Procedure for Electrical Connectors and Sockets.”

Why test Current Carrying Capacity?

Samtec’s products are used in a variety of conditions, and it is important for our customers to know how the products will perform. CCC is an important test because if the current rating is exceeded it will cause the product to overheat and fail.

Samtec publishes all of its reports on www.samtec.com and can be found according to the series pages. To see the qualification test report that includes CCC test results for the SEAM/SEAF series please click here, or type in the series name of the part you are interested in on samtec.com.