In my former role as a compliance engineer, I was repeatedly asked for Samtec’s Business Continuity Plan. This was normally part of a yearly vendor/supplier survey that ensures that a company could still supply products in the event of a disruption.

For most people, this isn’t something that really ever matters to them on the day to day (excluding those people in compliance); however, when something happens it had better be in place.

Oddly enough, this topic was on the schedule to be written about long before COVID-19 started wreaking havoc on every supply chain out there, and we are seeing business continuity plans in action almost everywhere.

What is a Business Continuity Plan?

On the surface, it makes sense to have a plan. We all want to be prepared for whatever comes our way, and often we do make “backup plans” personally so why not when it comes to business?

The simple answer here is that backup plans, contingencies, can often be expensive, or just not possible for a small business or even a large business. Buildings, equipment, staff, materials, tooling, etc all play a part in it, and can come at an extensive cost.

A business continuity plan is a guiding document that a company will put together to outline how that company will continue to operate during an unplanned occurrence/disruption. These disruptions can include:

- Natural Disasters / force majeure or acts of God: floods, blizzards, earthquakes, tornadoes, etc

- Accidents: fires, explosions, etc

- Utility Issues: communication, power, water, sewer outages

- Cyber Attacks

- Man made Disasters: pollution, spills, etc

The business continuity plan will contain contingencies for all areas of the business; including but not limited to human resources, equipment, buildings, etc. It also should layout processes that should be taken when an event occurs.

How does Samtec function?

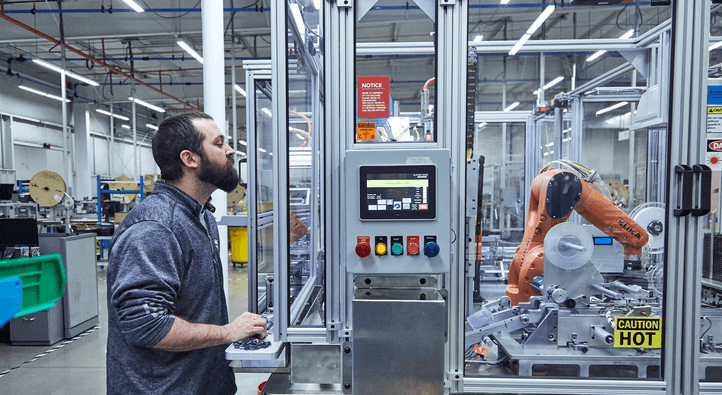

Samtec has always been well suited to take on whatever may come. This is due to our highly flexible manufacturing setup of at least dual manufacturing sites for most products.

Due to this setup, Samtec tests our ability to adjust to varying conditions daily. Many companies do not have that capability, but Samtec can switch plating locations, molding locations, and even assembly locations without issue.

Samtec currently has manufacturing capabilities in the USA, Costa Rica, Malaysia, China, and Vietnam. Many of these facilities have the capability to product the same products as the others, and this give us the ability to adjust for natural disasters, political unrest, pandemics, etc.

Our business continuity plan also includes contingencies (who to contact and what to do) for injuries, spills, emergency situations, weather emergencies, power outages, etc. Bottom line, Samtec is well prepared to address any number of issues that might arise.

For more information concerning Samtec’s business continuity plan, please contact [email protected].

Leave a Reply