Before we talk about electrostatic discharge (ESD), perhaps we should talk about where it comes from. You know what it is, and even young children know what causes it; static electricity.

Rub a balloon on your head, and make your hair stand on end, put on socks and drag your feet across the carpet, or slide down a plastic slide on the playground. No matter how you make it, you know what static electricity is when you are “fully charged.”

The conditions that afford static electricity to build are many, and with that in mind it is important to understand how to prevent it from building and causing an electrostatic discharge.

What is Static Electricity?

While it might seem like we are avoiding the topic of ESD, I assure you that static electricity matters. Triboelectric Charge, static electricity, matters because it causes ESD. Materials and people generate it, and we need to know how to stop it.

Static Electricity is caused by an imbalance of electrons on the surface of a material, and an imbalance occurs when a material either loses or acquires electrons.

The electron imbalance is the material’s Charge (Q) and is measured in Coulombs. For those keeping score, 1 Coulomb Flow in 1 second = 1 Amp or in a more practical sense would light a 120 W bulb for 1 second.

Why does ESD Matter?

Perhaps before we getting into why ESD matters, we should clearly define it. ESD is a rapid energy transfer from a static charged body or material to / from an Electrostatic Discharge Susceptible (ESDS) Electronic Device.

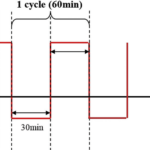

A proper ESD program will protect your equipment and products, and could end up saving your company money in the long run. Among the considerations for ESD control should be floors, work-surfaces, personnel grounding, ionization, packaging, training, and clothing to name a few.

Does ESD Affect Connectors?

In short, the answer is no. A majority of Samtec’s connectors are passive devices; excluding FireFlyTM for example. When looking at board-to-board connectors, it would be extremely difficult to damage them through ESD event since they are pins in plastic. However, this does not mean that Samtec takes ESD lightly.

In fact, Samtec recently introduced Severe Environment Testing (SET) in which several series are subjected to ESD Testing. We also have a series of blogs on SET that can be found here.

Samtec uses mitigating measures in areas where sensitive components / equipment are used. In these areas; special flooring, climate controls, ionizers, and other grounding techniques are used to control ESD.

If you have additional questions concerning how Samtec is testing connectors for ESD in Severe Environment Testing please contact [email protected]

Great article Brian. Thanks for sharing.

The control of electrostatic discharge is an important aspect when manufacturing, assembling and repairing devices that employ electronics. Electrostatic discharges can damage an electronic component at any stage of its production or application if not controlled