Collins Aerospace recently published a white paper entitled “Qualification Of High Density Connector Solutions For Military and Avionic Environments.” It discusses their qualification process of high density connectors for rugged military and avionics applications.

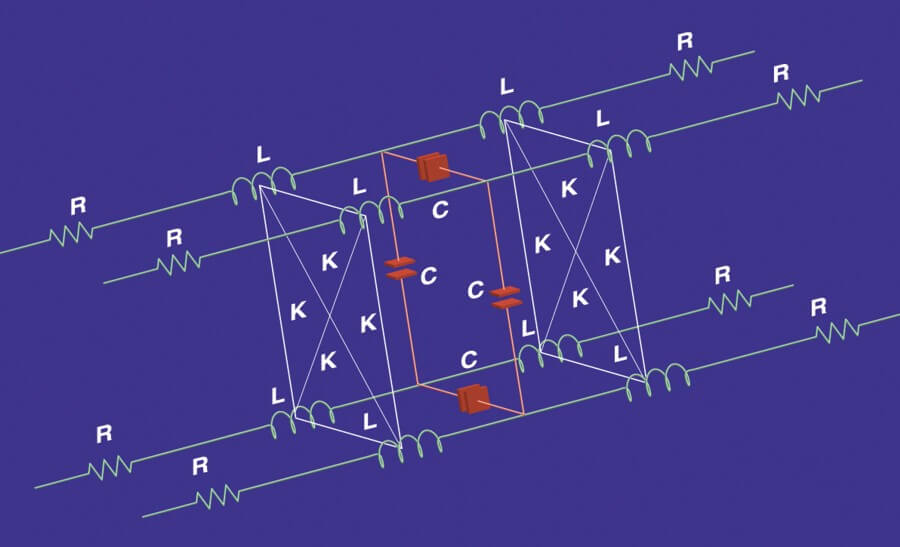

This paper focuses on the thermal testing of solder joints because “printed circuit board (PCB) assemblies are made up of many different materials that have different coefficient of thermal expansion (CTE) values. These differences generate mechanical stresses that can crack the weakest link in the assembly.” With connector solder joints, the problem is exacerbated because of the mismatch between the connector plastic housing and the PCB material.

The authors (Kim Cho, Tim Pearson, David Hillman, Ross Wilcoxon) point out that thermal cycle testing of connectors “has become increasingly important, due to the replacement of through-hole soldered pins and compliant lead frames with relatively non-compliant solder balls, solder pillars, and fine pitch ‘hockey stick’ style lead frames.” They also point out that solder joint reliability is an even bigger concern for military and avionics applications because thermal cycling extremes occur more frequently than in commercial applications.

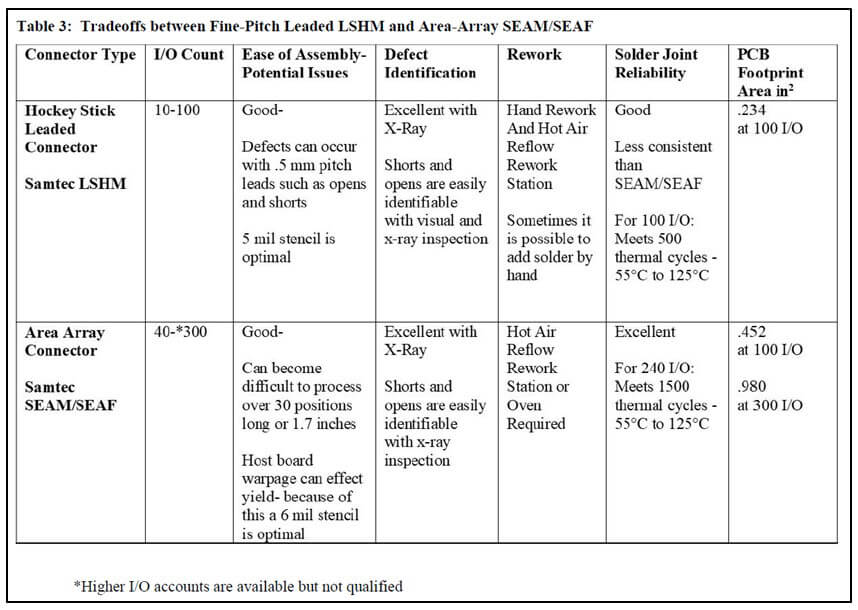

The study involved two Samtec product families: first is the LSHM micro (0.50 mm pitch), high density (up to 100 I/Os in a .232”2 (149.7 mm2) footprint) hermaphroditic mezzanine connector system. The second is the LPAF, LPAM high density (up to 400 I/Os in a 1.72”2 (1,110 mm2) footprint) grid array connector system. The report also references the previously tested SEAF, SEAM high density (up to 500 I/Os in a 1.77”2 (1,142 mm2) footprint) grid array connector system.

All connector sets were subjected to thermal cycles from -55°C to +125°C, with electrical continuity monitored throughout the entire process. The thermal cycles were tested according to IPC-9701 specifications.

The seven page paper details the test methodology, including:

- Test vehicle

- Test parts

- Assembly

- Thermal cycle testing

- Solder joint detection methodology

- Statistical analysis approach

- Cross sectional analysis

The paper also discusses the tradeoffs between the two connector lead styles, including a comprehensive table (Table 3, page 6), the “Tradeoffs between Fine-Pitch Leaded LSHM and Area-Array SEAM/SEAF.”

We’ll let you read the conclusions, but in brief summary:

- Vertical LPAM, LPAF connectors: no failures occurring in 2,000 thermal cycles

- Vertical SEAM, SEAF connectors: failures occurring after 1,500 thermal cycles

- Vertical and horizontal LSHM connectors: with failures occurring after 500 thermal cycles

- The choice of solder alloy (tin-lead and lead-free) was not a significant factor in influencing reliability

Hopefully this brief summary tells you the most important points of the paper, but we encourage you to read (or skim!) the entire paper for yourself.

Leave a Reply