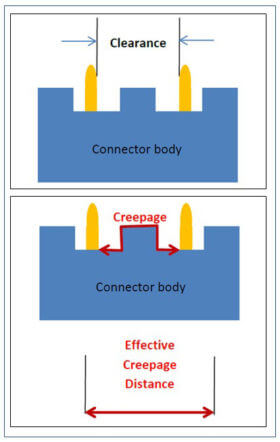

Every day Samtec’s Application Support Group answers questions about a connector’s mechanical, thermal, and electrical performance. One frequently discussed topic is connector creepage and clearance. Creepage and clearance is ultimately about safety and meeting regulatory standards, regardless of the system design. The ongoing trends to reduce PCB size and increase density become a design challenge when these smaller, denser PCBs incorporate high voltage circuits.

Dave Scopelliti, President of D-Scope-Tech and a long-time friend of Samtec, prepared an excellent document on creepage and clearance. Here’s the link to the complete document: Clearance and Creepage. I think it’s better to read (or scan) the complete eight page document, so I’m sharing the link above. But if you prefer to see a quick overview, here’s a summary:

What is Creepage and Clearance and Why Do We Care About It?

These are actually two simple concepts and are product safety terms and requirements for many types of products/assemblies/components. Regulating agencies such as IEC, UL and CSA have very specific product application guidelines and requirements that must be met in order to sell said products in many countries. These standards help to ensure safe operation of the products reducing the risk of electric shock or other injuries to the end users as well as reducing fire hazards.

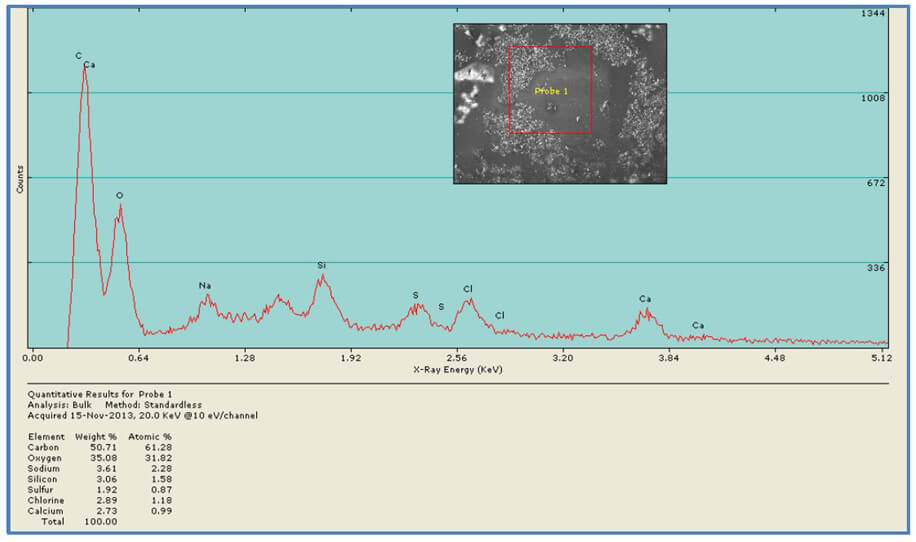

The paper defines creepage and clearance and explains why there are two different requirements. Dave also elaborates on how carbon traces affect the PCB after an arc occurs.

Pollution Degree

Dave explains pollution degree and ratings, and gives an example of how pollution can degrade insulation resistance and withstanding voltage. Pollution degree is an application specific parameter that takes into account how pollutants will affect products exposed to different environments from a high voltage/safety standpoint.

Industry Standards and Specifications

The paper concludes with an excerpt from the Clearance section of many of the related industry standards (from IEC 62368-1, Audio-video, Information and Communication Technology Equipment) that illustrates clearance requirements in the range most likely encountered in telecommunications and most consumer applications.

Other Links That May Be Of Interest:

- Creepage and Clearance Specs On Samtec “Tech Spec” Pages

- Solder .15 mm Coplanarity ConnectorsWith a .10 mm Stencil

- Dissimilar Metals And The Risk Of Galvanic Corrosion in Mating Connectors

- Interconnect Susceptibility To Galvanic Corrosion

- Multiple Connector Alignment On Mating PCBs

- Interconnect Test Report Frequently Asked Questions

- Advice On Selecting and Processing Connectors

- Guidelines To Ensure Electromagnetic Immunity In Connectors

- Guidelines For Paste-In-Hole Reflow Processing

- Fretting Over Fretting Corrosion

- Best Practices For Connector Models

- FAQ Interconnect Test Reports