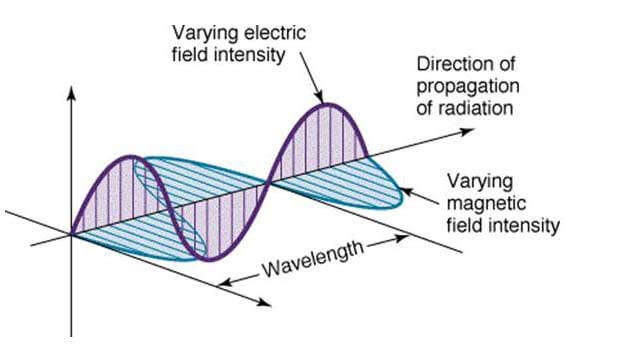

Electromagnetic Immunity is the ability of a system to continue functioning in the presence of electrical noise. One can imagine a scenario where an automobile drives under a cell phone tower. If the automobile accelerates to 120 mph due to coupled noise in the engine controller from the cell phone tower, one can say that the automobile is vulnerable to noise from the cell phone tower.

Regulations

This simple (but dramatic) example illustrates the need for immunity testing and requirements for electronic products. Federal agencies regulate these requirements and they vary by nation and by product. Where human life is potentially at risk, regulations are stricter. Medical devices, transportation and aerospace are industries more heavily regulated for electromagnetic immunity.

In the U.S. there are no federal immunity requirements for Information Technology Equipment (ITE) or computing hardware. The Federal Communication Commission (FCC) only regulates electromagnetic emissions, or the energy emitted from computing hardware. In the European Union however there are numerous immunity requirements which include radiated immunity, conducted immunity, surge and ESD.

While it is possible to develop computing hardware for regional sales, it is generally more efficient to develop electronic products for a global audience. This means that the most restrictive immunity requirements need to be adhered to for unfettered global distribution.

Samtec manufactures cable assemblies and connectors which have a unique role in immunity performance. By themselves, these products are inherently immune but they can act as conduits for noise to enter and disrupt sensitive electronics. For example, an ESD transient can be applied to a connector pin and that energy can travel to an IC then fuse a transceiver semiconductor junction.

Guidelines To Ensure Electromagnetic Immunity

Electromagnetic immunity is a system requirement applicable to functioning electronics and the design of the system will determine compliance. Some general connector guidelines for immunity design are as follows:

- All I/O should be filtered, shielded or both. Since I/O is the conduit for external noise to disrupt electronics it should be treated protected

- I/O should be physically separated and electrically isolated from sensitive circuitry. The idea here is to prevent secondary coupling of the external noise as much as possible

- Connectors should not have unterminated pins. “Floating pins” or connector pins that are not connected to ground or terminated in some manner can enhance coupling of the external noise to sensitive internal electronics.

- If a connector or cable is shielded, be sure the shield is connected to chassis ground. This is typically performed at the panel interface.

Note that these guidelines need to be applied to all connectors, otherwise it’s like having done nothing at all. If you fix four out of the five holes in a cup, the cup still leaks.

A general list of design practices is a good starting point but it always wise to have specific recommendations from an engineering specialist versed in electromagnetic immunity design practices.

Jim Nadolny is Samtec’s Principle SI and EMI Engineer.

Other links of interest:

- Samtec Signal Integrity Group

- Email the Signal Integrity Group

- Teraspeed Consulting