While creepage and clearance sounds like something that’s a misdemeanor in most states, we are asked about it frequently. Why all the questions? Either it’s not a crime in Indiana, or designers are asking about higher voltage connector systems.

Creepage and clearance is ultimately about safety and meeting regulatory standards, regardless of the system design. And, the ongoing trends to reduce PCB size and increase density become a design challenge when these smaller, denser PCBs incorporate high voltage circuits.

Creepage and Clearance Defined

Designers are usually trying to reach UL and CE 61800-5-1 specs that call out creepage and clearance distance given material grade, working voltage, and pollution degree. While I may be oversimplifying matters, at the end of the day we’re trying to avoid arcing.

Here’s a quick review of the definitions just to make sure we’re on the same page.

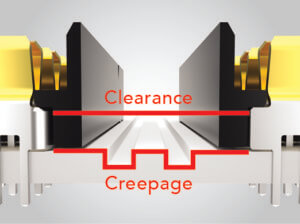

Creepage is the shortest distance along the surface of a solid insulating material between two conductive parts.

Clearance is the shortest distance in air between two conductive parts.

A creepage distance can’t be less than the clearance distance; in other words, the shortest creepage distance will be equal to the clearance distance.

Connector manufacturers can increase creepage distances by adding grooves, notches, or plastic planes (i.e., walls) on the connector’s plastic insulator. This increases the physical distance on the surface of the plastic insulator. See the illustration above right for a design that incorporates grooves to increase the creepage distance.

Locating Creepage and Clearance Specs

While creepage and clearance are simple values, we’ve been told it can be extremely difficult to locate them on some connector supplier’s websites. We try to make it easy to find. Samtec has several resources that can help you locate a connector system that will meet their creepage and clearance specs for power products.

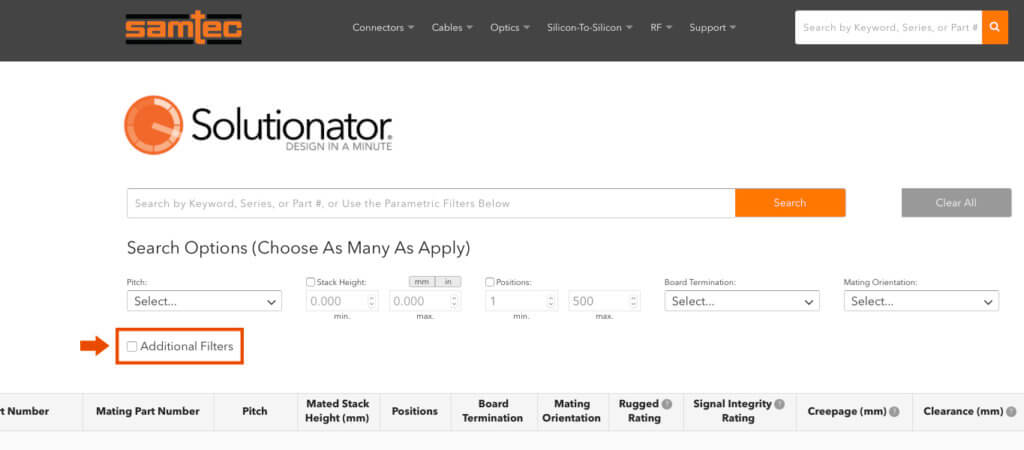

First is Solutionator, our parametric search tool that makes it easy to find the best Samtec socket and terminal set based on your design requirements. Solutionator is different because it doesn’t give you one just connector – it gives you the part numbers of both the mated socket and terminal strips that meet your design criteria. This is the only search tool that provides such a complete solution.

One of the search parameters is creepage and clearance. If you want to check it out, open the Solutionator page, and select the “Additional Filters” box under “Search Options” (see the screen capture below).

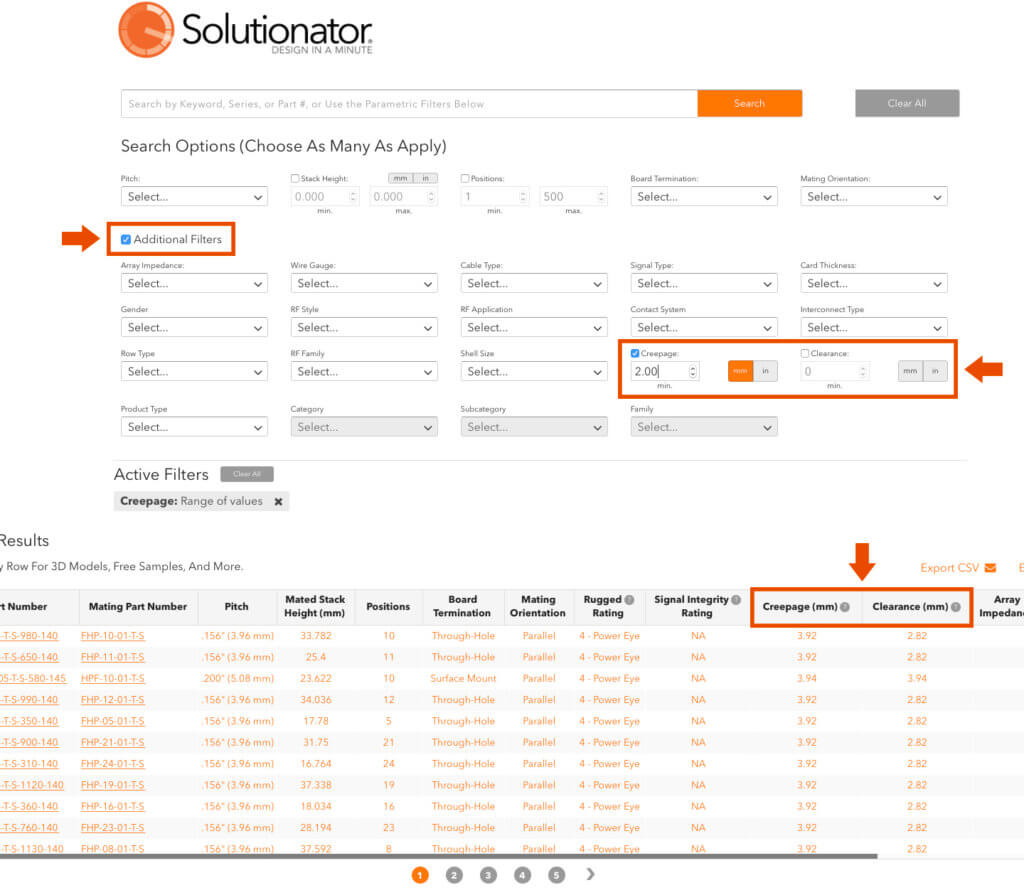

When you do this, about 19 additional search boxes appear. Look over to the right and you will see a box to enter either the creepage or clearance distance. I selected 2.00 mm in the example below. The list of mated connector sets that meet that criteria then appears below the additional filters, although you may have to scroll down a bit to see them. Again, see the screen capture below.

Second, creepage and clearance specs are listed on the catalog page for every power product. You’ll find them in the left-hand margin.

Also, we can selectively load contacts to achieve customer-specific creepage and clearance requirements. This is a common application to meet both creepage and clearance distances. For additional support, contact [email protected].

Other Links That May Be Of Interest

- Multiple Connector Alignment On Mating PCBs

- FAQ Interconnect Test Reports

- Dissimilar Metals And The Risk Of Galvanic Corrosion in Mating Connectors

- Interconnect Susceptibility To Galvanic Corrosion

- Advice On Selecting and Processing Connectors

- Guidelines To Ensure Electromagnetic Immunity In Connectors

- Guidelines For Paste-In-Hole Reflow Processing

- Fretting Over Fretting Corrosion

- Best Practices For Connector Models