Many Samtec customers employ Paste-In-Hole (PIH) processing. Very simply put, this is the process of screening solder paste into and around plated through-holes on a pcb, and placing the leads of through-hole components — like connectors — in these prepared through-holes. The boards are run through a reflow soldering process, thus terminating both through-hole and SMT components in one reflow process.

Advantages of Paste-In-Hole Technology

- It saves time because it employs only one process – reflow only

- It also saves money because, again, there is only one process – reflow only

- The strength of the PIH solder joint is comparable to those of traditional through hole solder joints

- PIH makes it easier to process double sided boards, especially with taller components

Can any connector be used in PIH?

To be a candidate for paste in hole soldering, a connector must meet two requirements.

First, the insulator body material must be capable of withstanding lead and/or lead-free reflow temperatures.

Second, the vertical and horizontal clearance around the leads must be large enough to allow adequate printed solder paste volume. This vertical and horizontal space is required to allow unobstructed transfer of the molten paste from the pcb surface into the plated through hole.

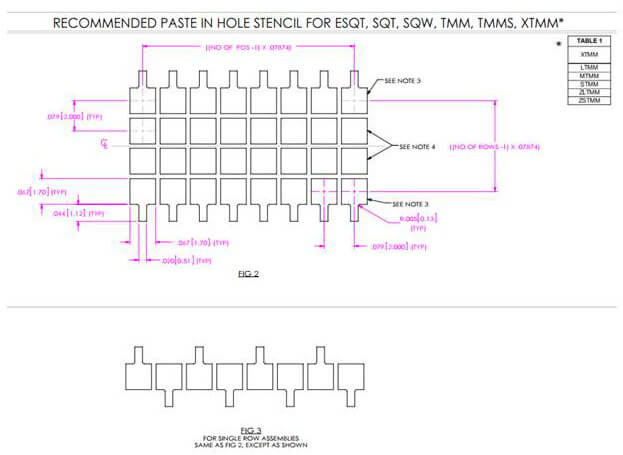

Samtec provides the recommended stencil aperture and plated through-hole sizes for most connector series capable of being processed using Paste-In-Hole technology on the connector footprint. Samtec’s stencil aperture recommendations are calculated using:

- The nominal plated through-hole diameter found on the connector footprint

- The nominal connector tail dimensions

- 0.062″ [1.57 mm] printed circuit board thickness, unless otherwise noted

Below is a typical PIH recommended stencil for 2mm pitch header strips.

Please note that boards thicker than 0.062″ (1.57 mm) require larger stencil apertures to provide the needed solder volume. Therefore, depending on the connector geometry, some may not be suitable for paste in hole technology on boards thicker than 0.062″ (1.57 mm).

Samtec’s Interconnect Processing Group (IPG) is an in-house staff of engineers to support your interconnect processing concerns. IPG can assist you to improve the overall processing and manufacturability of your board as well as help lower its total applied cost.

We welcome your questions; you can contact us directly. Here’s a list of a few product series that customers use for paste in hole reflow (there are plenty others, but these are the most popular):

- ESQ (.100″ pitch socket strip for PC/104)

- HTSW (.100″ terminal strip)

- ESQT (2mm pitch socket strip for PC/104 Plus)

- TMMH (2mm pitch terminal strip)

Additional Paste-In-Hole Resources:

- Here’s a link to our most frequently requested interconnect processing guidelines

- And here’s a link to FAQs about interconnect processing