Edge card connectors — or are they card edge connectors? — are a popular design option. That’s because they make it easy to plug and unplug a mating card that may require more cycling than standard PCBs, and because the socket allows for relatively easy system upgrades and repairs, and there’s less cost with only one connector, and less processing time also.

Interest and usage of micro pitch edge card connectors continues to grow. As with any micro-pitch interconnect, the stresses of repeated cycling can test the relatively small connector tails and minimal solder paste.

What are some steps you can take to ruggedize your micro edge card connector? Glad you asked!

Weld Tabs & Locking Clips

Small weld tabs, either through-hole or SMT, are commonly used to increase the mechanical strength of the connector to the PCN. The SMT weld tabs are soldered to pads on the PCB. The tabs have no electrical function, and the additional cost is minimal because they are frequently tin plated and made of a low-cost material like brass.

Through-hole locking clips, similar to weld tabs, also increase the mechanical strength of the part to the board.

Besides optional design features which increase the mechanical strength of the part to the main PCB, the connector itself can be designed to make it more rugged. This includes the body and contact design.

Insulator Design

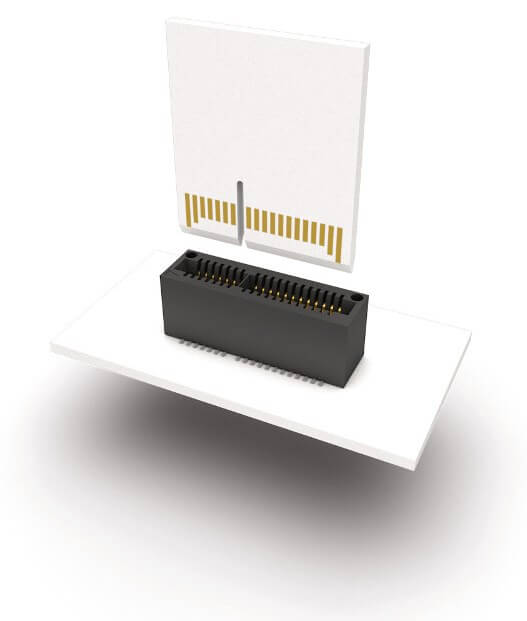

A new micro edgecard socket recently released by Samtec is the HTEC8 series. The HTEC8 accommodates blunt-end edge cards (i.e., mating PCBs) without risking damage to the contact. Many designers use chamfered edge cards to minimize the risk of the mating card damaging the contact in the socket. The narrowed, chamfered edge is much less likely to catch. Conversely, the chances of damaging the connector contacts increases with blunt-end edge cards.

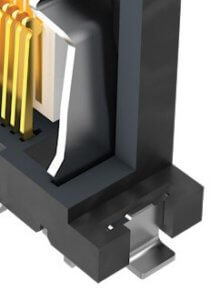

The tips of the contacts on the HTEC8 are protected because they are locaated behind the plastic housing. This prevents a blunt-ended card from catching and possibly bending the contact.

Guide rails are also available to ensure proper alignment of the mating edgecard. Misalignment during mating on the Y axis can stress and possibly damage contacts.

Contact Design

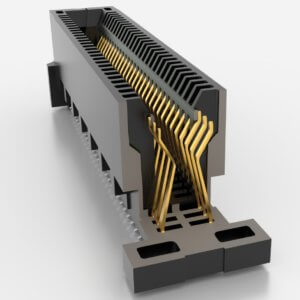

Likewise, a quality contact design can increase the overall performance and ruggedness of the edgecard connector.

The Samtec Edge Rate® contact system is used in many micro pitch edgecard socket strips. Rugged Edge Rate contacts are designed for high cycle applications. First, the contact material is beryllium copper to optimize spring properties. Second, the pads on the edgecard mate with the smooth side of the contact, increasing the plating life of the edgecard pads.

Other Good Reading Material

- Here’s a blog about processing micro edgecard sockets and a new product with a card justification beam.

- Here’s a blog with guidelines on how to handle alignment issues when you have multiple connectors on PCBs.

- Here’s one with guidelines for paste-in-hole reflow processing.

- And here’s one covering FAQs about interconnect test reports.

Interconnect Processing Group

Do you have any questions? Or do you have other processing-related issues where you would benefit from a qualified opinion? The Samtec Interconnect Processing Group is an in-house staff of engineers who address your questions about interconnect processing issues. IPG can assist you in improving the overall processing and manufacturability of your board as well as helping lower its total applied cost. Here’s a link to get you in touch with IPG.

Leave a Reply