It seems like everyone is thinking about the global coronavirus scare, and rightfully so. Workers, students and those most as risk are staying home. What are people doing at home? They are probably binge-watching their favorite video streaming service.

It appears not even COVID-19 can slow consumers’ insatiable demand for data. This puts constant pressure on internet providers, equipment vendors and components suppliers to develop higher-performance networks.

Samtec is a global leader in developing 112 Gbps interconnect solutions. A great example is NovaRay® 112 Gbps PAM Extreme Density Arrays. The NovaRay® family is intended for next-gen data center architectures.

How can Samtec attain such performance? What goes into the design process? Samtec SI expert Scott McMorrow answered these questions and more in the Ansys booth at DesignCon 2020.

Design, Simulate, Repeat

In reality, that is Samtec’s approach to high-performance interconnect design. Oh, if it were that simple. The connector design, both mechanical and electrical, can take months using the latest CAD software.

What about simulation? That is where the fun begins! In the video below, Mr. McMorrow details how Samtec engineers leverage the multi-physics modeling and simulation capabilities of ANSYS® HFSS™.

In the video, Mr. McMorrow states that ANSYS® HFSS™ is the highest-performance 3D solver available. Optimizing performance means simulating the interconnect in the presence of both electric and magnetic fields.

For Samtec, design and EM simulation are not a one-time step. The interconnect design can change. Why? To achieve the desired simulated results.

In the video, Mr. McMorrow highlights the power of ANSYS® HFSS™. It can design and simulate various PCB routing designs. Specifically, Samtec simulates the effect of route radius shape and size on RL and TDR performance.

112 Gbps PAM4 Key: Correlation

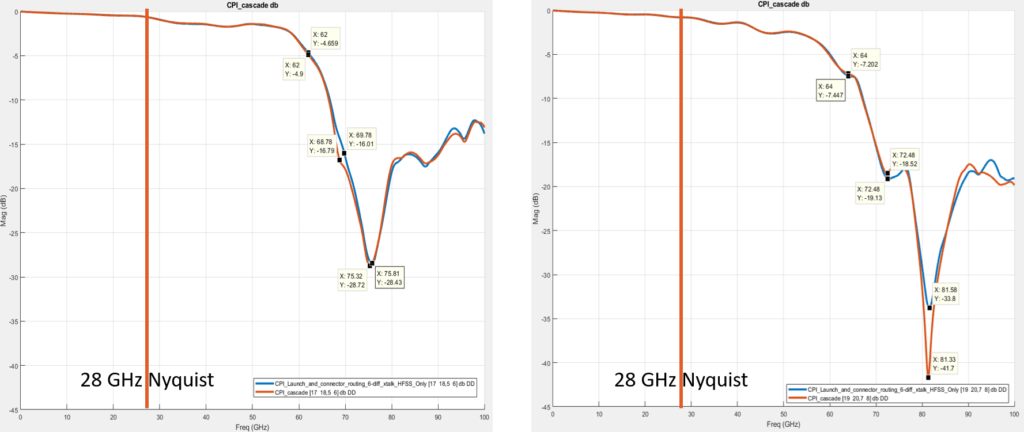

At Samtec, correlation is a key design goal for high-performance interconnect design. In short, correlation occurs when tested and measured data correlates, or closely copies, the simulated data.

For interconnect design, a sample is built. The sample is placed on an SI Evaluation Kit for testing and measurement. Typical measurements include IL, RL, TDR and XTLK.

Additionally, Mr. McMorrow illustrated this with Samtec’s new Si-Fly™ 112 Gbps PAM4 Low-Profile, High-Density Cable System. Si-Fly™ eludes the BGA. Signals are routed directly from the silicon package through a long-reach cable.

For instance, both graphs show a comparison between Si-Fly insertion loss when simulated with two different methods. The first contains a complete model of the package and connector.

The second contains a “sectioned” model where the package and connector are modeled separately in significantly reduced time. Most importantly, both methods provide almost exactly identical results.

For more information, please contact our SI technical experts at [email protected].

Leave a Reply