Edge Rate® is one of Samtec’s most popular high-speed, high-bandwidth interconnect systems. Edge Rate is both the name of the pin and in this case, it’s also a product family.

Edge Rate Contact Design

Let’s begin with the contact system because that’s the star of the show.

With some connectors, the mating edge of the contact is the cut edge of the pin. If you look at the edge under a microscope you may see micro burrs and edges. This reduces the life of the connector because repeated cycles against those cut edges will wear out the plating.

But, the mating surface of the Edge Rate contact is the smooth, milled side of the contact. This smooth mating surface reduces wear tracks on the contact, increasing the durability and cycle life of the contact system.

Also, the Edge Rate contact is rugged and can handle high-cycle applications. The contact wipe on the .8mm and .5mm pitch products is 1.5 mm for a reliable connection.

Second, the thin, narrow, cut edges of the Edge Rage contact are positioned side-by-side. This minimizes the parallel surface areas, which reduces broadside coupling and crosstalk.

Third, the contact is simply designed for higher bandwidth. The contact geometry is designed, simulated, and optimized for 50 and 100-ohm systems given the contract pitch and appropriate grounding schematics.

Since Edge Rate connectors don’t have ground planes, they take up about 15% less PCB real estate than connector strips with said ground planes. And, since there’s no ground plane, depending on the quantity ordered, they can be significantly lower priced.

(BTW, you might also be interested in this blog about different contact systems: Select The Best Connector Contact and Pin)

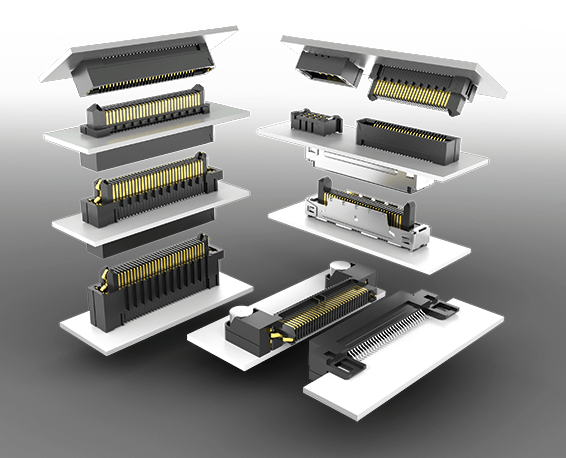

Edge Rate Connectors

The connectors are the ERM and ERF series. You guessed it: ERM stands for Edge Rate Male, and ERF stands for Edge Rate Female. These three letters are followed by either an 8, 5, or a 6. Eight is for 0.80 mm pitch, 5 is for 0.50 mm pitch, and 6 is for 27 mm pitch. Just kidding, 6 is for 0.635 mm pitch.

The new ERM6, ERF6, on 0.635 mm pitch, saves space on the board. The slim body design is only 2.5 mm wide, or just under .100”. That’s big. Well, I mean it’s a small connector, but it’s a big deal.

Edge Rate connectors are available in vertical, right angle, and edge mount terminations. They are available with all kinds of design options, like full 360-degree shielding, latching systems, guide posts, and differential pair configurations, to name a few.

Adding all that up, here’s what’s the full line of Edge Rate rugged, high-speed strip connectors:

- ERM8 (0.80 mm Pitch, Mezzanine Terminal Strip)

- ERF8 (0.80 mm Pitch, Mezzanine Socket Strip)

- ERM8-RA (0.80 mm Pitch, Right Angle Terminal Strip)

- ERF8-RA (0.80 mm Ptich, Right Angle Socket Strip)

- ERM8-EM (0.80 mm Pitch, Edge Mount Terminal Strip)

- ERF8-EM (0.80 mm Pitch, Edge Mount Socket Strip)

- ERM5 (0.50 mm Pitch, Mezzanine Terminal Strip)

- ERF5 (0.50 mm Pitch, Mezzanine Socket Strip)

- ERF5-RA (0.50 mm Pitch, Right Angle Socket Strip)

- ERM6 (0.635 mm Pitch, Mezzanine Terminal Strip)

- ERF6 (0.635 mm Pitch, Mezzanine Socket Strip)

In Summary …

- Edge Rate contacts are rugged and designed for higher-cycle applications.

- They’re high speed – depending on the configuration they’re rated at 28 Gbps or 56 Gbps PAM4.

- There are lots of design options.

- And without a ground plane, Edge Rate saves space on the PCB and is lower cost.

If you have any questions please contact the Samtec Application Support Group.

And if you’ve stayed with me this long, below is an old topical ad that we ran on our website years ago, when we first introduced Edge Rate. Read this if you’re wondering why we have a tiger in our ads.

Leave a Reply