As computing power continues to increase, air cooled systems cannot meet current thermal requirements for HPC hardware systems. Power consumption, space and performance must all be considered during system design. Immersion cooling is a fast-growing solution to economically combat system heat, noise, power consumption and compute density.

Samtec’s Brian Niehoff presented “Thermal Management of HPC Hardware Architecture via Immersion Cooling” at the Exhibitor Forum at SC20. Brian’s presentation includes discussions of the challenges, costs, and considerations of air, liquid, and immersion cooling. He discusses immersion cooling techniques, and he compares the test results of connectors in both air cooling and immersion cooling environments.

Since this is a Samtec blog, of course we’re going to on the results of the connector testing. Samtec performed the following tests on a variety of connector products, in both air-cooled and in a single phase immersion cooling environment:

- Mating/unmating/durability

- IR/DWV

- CCC

- CC

- LLCR

- Thermal Shock

- Thermal Age

- SI Testing

Samtec products either tested or scheduled to be tested include:

- SEAM, SEAF (SEARAY™) high density grid arrays (complete)

- ET60T, ET60S (EXTreme Ten60 Power™) power/signal connectors (complete)

- UMPT, UMPS (mPower®) micro power connector (in-testing)

- ERM8, ERF8 (Edge Rate®) rugged high speed system (in-testing)

- QTE, QSE (Q Strip®) high speed ground plane system

- SFM, TFM (Tiger Eye™) high reliability system

- MPT, MPS (PowerStrip™/30) dual blade power connectors

- UEC5 (FireFly™) socket connector for optical engine cable assembly

- IPBT, IPBS (Power Mate®) isolated power strips

We partnered with our friends at Engineered Fluids; they manufacture the single phase immersion cooling liquid used in the tests (EC-130).

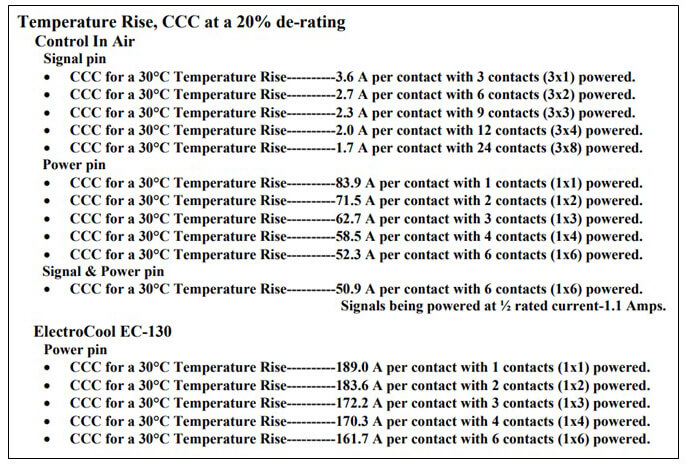

Space doesn’t allow us to share all of the test results. But we can tell you that the results have been significant. For example, looking at current carrying capacity (CCC) for the ET60S, ET60T power/signal connector system – in an air-cooled system — the CCC for a 30° C temperature rise is 52.3 A per contact with 6 contacts powered (1 x 6). The equivalent CCC in the immersion cooled environment is 161.7 A.

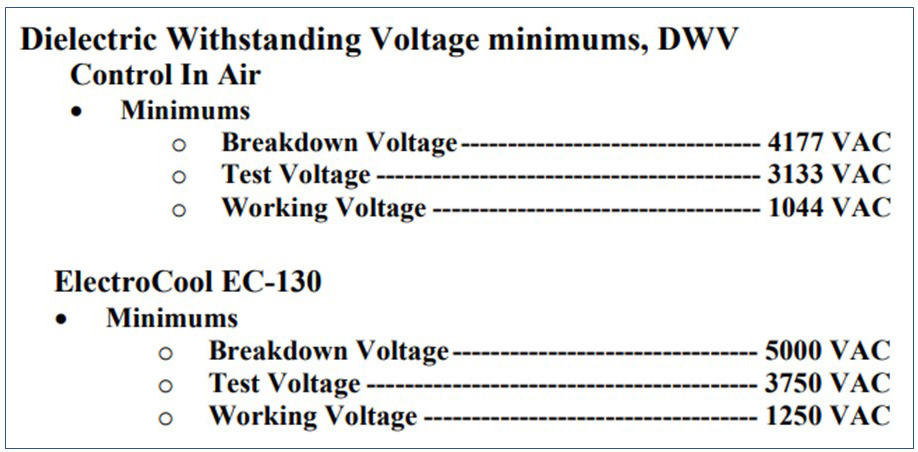

Similarly, looking at the dieletric withstanding voltage (DWV) test for the same connector system – in an air-cooled environment – the breakdown voltage is 4,177 VAC. In a immersion cooled system the breakdown voltage is 5,000 VAC.

Click here if want to see full product test reports, comparing the results of air-cooled connectors to the results of the same immersion cooled products.

Besides traditional two-piece board-to-board connectors, we also have a FireFly™ active optical engine cable assembly that can be used in immersion cooling systems. The immersion process has no impact on the RF or optical performance of this sealed optical transceiver system. This was tested on a Xilinx VCU 118 development board, with 2,000 hours of submersion completed, pressure to 60 psi, and tested in 3M™ Fluorinert™ FC-43.

Click here if you want to see a video demonstration of the immersion cooled active optical engine system, or you can also click here to see another video, or you can learn about our salt-fog resistant optical modules.

Leave a Reply