J.R. Bonnefoy, Systems Engineer at Samtec, walks us through a live product demonstration of a 70 GHz, high-performance test point system. This demo, from DesignCon 2020, incorporates two new high-performance products.

The demo is based on Samtec’s 56 Gbps PAM4 Product Demonstration Platform. It emulates real-world 56 Gbps PAM4 design challenges which pairs bleeding edge silicon and interconnect solutions using real-world, optimized design practices.

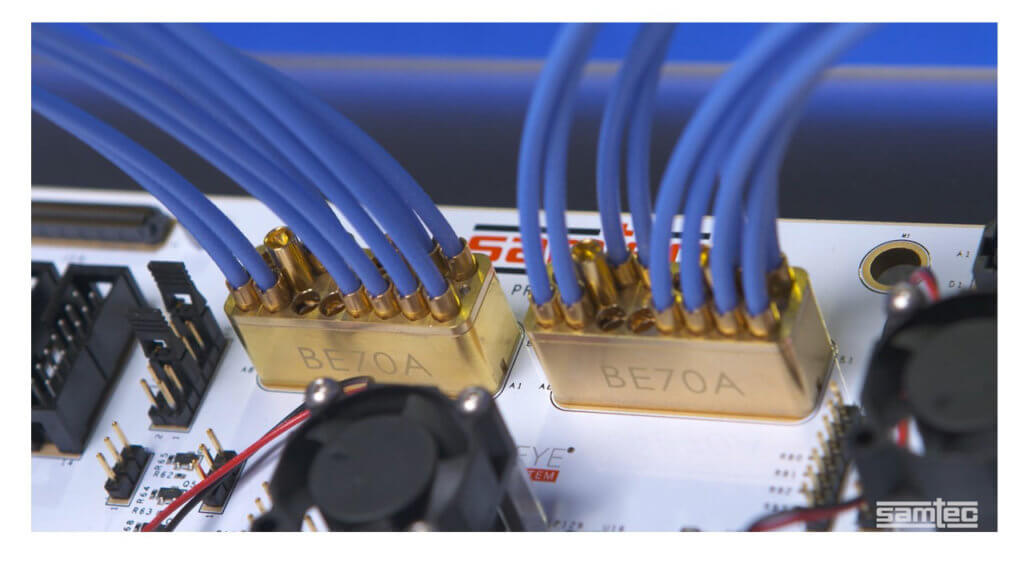

This demonstration focuses on the Samtec Bulls Eye® test point system.

Signal Path

A Credo Bald Eagle 2 retimer transmits QPRBS31 pattern signals at 56 Gbps PAM4 data rates on five separate channels.

These signals run differentially, through about 1.5” of PCB trace to the 70 GHz, Samtec BE70A Bulls Eye high-performance test point system.

The signals travel from the Bulls Eye connector, through phased match pairs of Samtec low-loss microwave coax cable, terminated with 2.4 mm precision RF connectors.

These connectors are mated to a Samtec SI evaluation board for our new NovaRay™ extreme density arrays.

The signals travel from the coax cables, through the evaluation boards, through a Samtec NovaRay connector set, through the second NovaRay SI eval board, through another set of high-performance precision RF 2.4 mm cables, and back to the Bulls Eye connector.

Finally, the data lanes circle back to the Credo Bald Eagle 2 receiver, where the data is recovered nicely.

Results

Specifically, we see zero errors, which is impressive for 56 Gbps PAM4 modulations. The eyes are wide-open, with eye heights ranging from 180 to 248 mV, which leads to very low bit error rates. In this case, BER is e-15.

This demonstration shows how Bulls Eye can be used effectively in a real-life evaluation board environment.

Samtec can bring the 56 Gbps Product Demonstrator to your lab or office if you’d like to see first-hand how Samtec high performance products can fit in your system.

Bulls Eye

Bulls Eye is ideal for high-performance test-point applications because of its compression interface, small footprint and high cycle count. Specifically, the connector grid design and smaller footprint enable smaller evaluation boards and shorter trace lengths.

This high-density design significantly saves PCB space compared to traditional test points.

The compression interface to the board provides easy on/off and eliminates soldering costs, and is available for both microstrip and stripline transmission types.

The contacts are designed for high cycle counts, and replacement components are easy to order.

Thanks to Samtec ultra low loss 086 microwave cable and precision interconnects, Bull seye enables optimized performance to 70 GHz.

NovaRay

NovaRay® is our new extreme density array connector system rated at 112 Gbps PAM4 per channel. The fully-shielded differential pair design enables extremely low crosstalk, tight impedance control, and minimal variance in data rate as stack height increases.

Multiple points of contact guarantee two points of contact, which ensures a more reliable connection and stub-free mating.

NovaRay has 112 differential pairs per square inch, which contributes to an industry-leading 4.0 Tbps aggregate data rate.

For more information on Bulls Eye, including the new 70 GHz products, go to samtec.com/bullseye, and to learn more about NovaRay go to samtec.com/novaray. If you have questions about this demo, email us at [email protected]

I think should be mentioned also few words about DFE and FFE is used

I’m wondering if this is as good as a torque wrench on an coaxial test point. If one can use a “compression” contact in place of a coaxial test point why then are there torque requirements on coaxial connectors for good measurements? Why are there screw-on coaxial connectors on the front face of test equipment instead of cheaper compression contacts? Surely a spring is going to loose its ability to compress over time right?