While air cooling is still a commonly used method to cool data centers, the industry is seeing HPC, AI, and scientific computing market leaders investigating either conduction cooling, or full-scale immersion cooling, for their next generation designs.

In this video from SuperComputing 2019, Arlon Martin and the Samtec Optical Group are demonstrating the latest developments in full-scale immersion cooling.

Using Samtec Flyover® technology and FireFly™ optical modules as an example, Arlon explains the tradeoffs between air, conduction and liquid cooling.

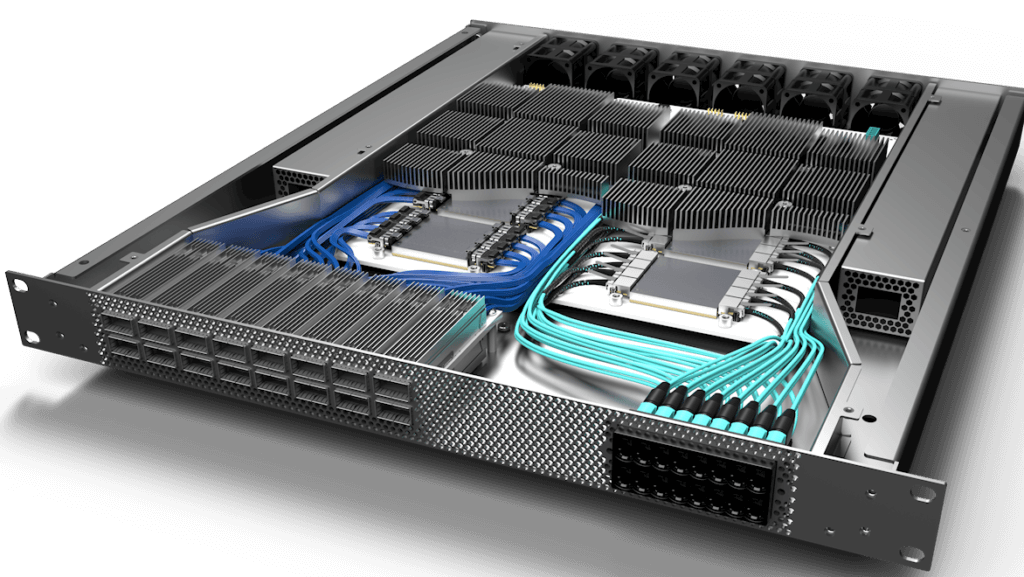

The demo shows a 1RU compute switch with Samtec Direct Connect Technology. The switch incorporates a row of fans along the back panel to draw the cool air through the row of QSFP-DD transceivers on the front panel.

However, in this example, these five fans alone are consuming 30 W each, for a total of 150 W. Fans are part of every switch blade or server blade in an air-cooled computing system. In fact, cooling accounts for 30 to 35% of the total power consumption of a typical air-cooled super computer.

Conduction cooling and immersion cooling are both more energy efficient than air cooling.

With conduction cooling, a cold plate with liquid running through the plate contacts the FireFly optical modules.

Power is reduced three ways. First, FireFly embedded optical modules themselves use less power, because they are smaller and placed mid-board, next to the FPGA. This results in roughly 25% less power consumption than an equivalent front panel pluggable version.

Second, contact cooling is better at heat transfer than air. The thermal conductivity of copper is 15,000 times better than air.

Third, the Samtec FireFly system increases board density. Reduced power consumption and improved density are the key drivers why COBO and Co-Packaged Optics techniques are receiving so much attention as interconnect options for next generation switches and servers.

The most energy efficient solutions use full immersion cooling. Here the entire board, optics included, is submersed in a non-conductive liquid. The heat transfer is faster, the boards can be even denser, and cooling system uses less power.

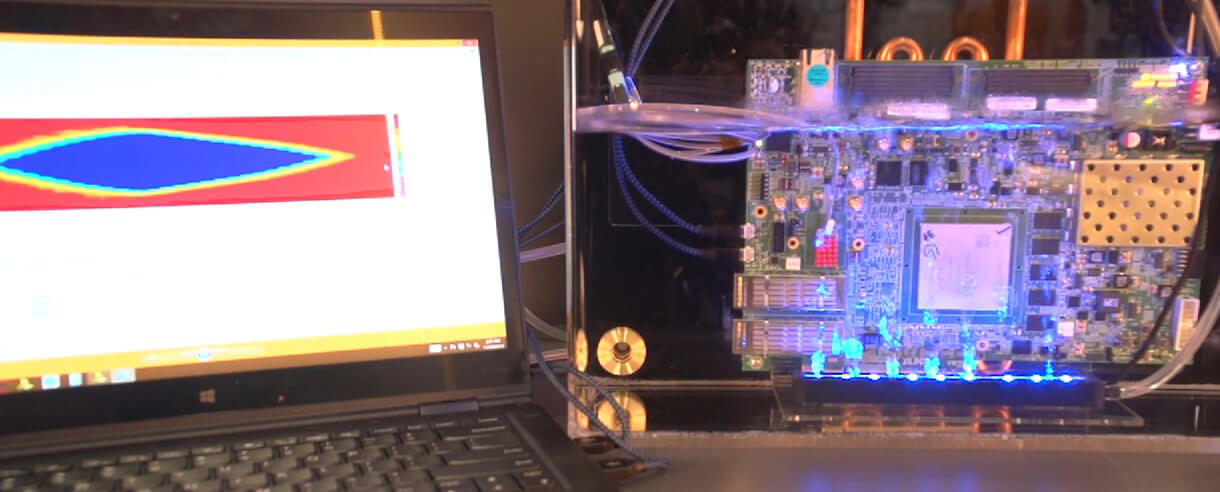

In the featured demonstration, a Samtec FireFly optical transceiver supports 100G Ethernet and is running at 112 Gpbs (x4, 28 Gbps/lane), with fantastic BER results. It works in virtually any submersible environment. Inside the critical components are all sealed to ensure high reliability.

In this demonstration the FireFly and Xilinx VCU 118 development board are fully submersed in 3M™ Fluorinert™ Electronic Liquid FC-43.

The FireFly transceiver is a mid-board optical module which is less than 25% of the size of a QSFP module, and it uses less than 50% of the power of a normal transceiver. This allows for very dense, high performance computing applications.

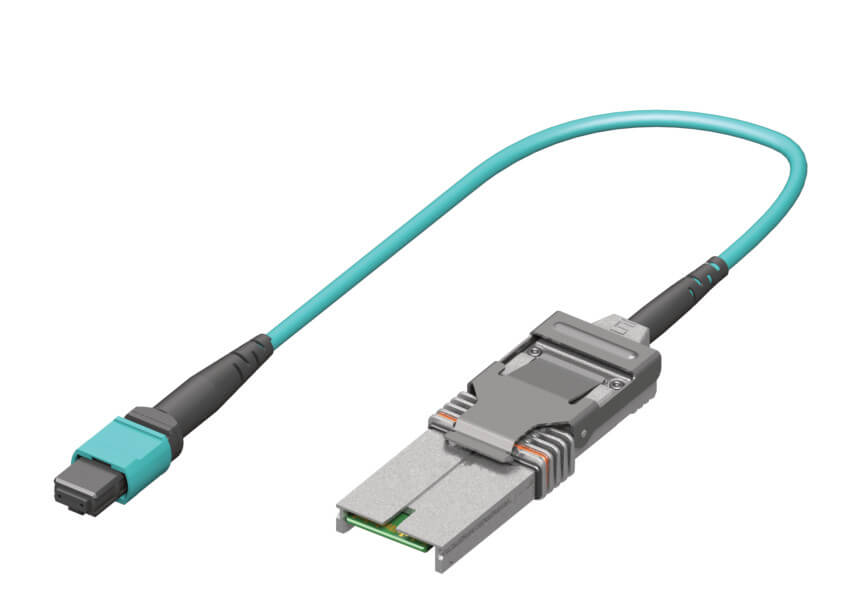

FireFly micro cable assembly systems are available in both optical and copper designs. Both systems use the same two-piece, low insertion force connector system with surface mount tails to eliminate through-holes in the board.

Samtec is the only company to offer both a copper version and an optical version in the same connector. We are also the only company to offer submersible, embedded optical transceivers.

If you want to learn more check-out samtec.com/FireFly. Or email us at [email protected].

You may also want to check out “Removing Heat and Noise With Submersible Cooling.”

Leave a Reply