In his latest paper, Dave Scopelitti explains the ins-and-outs of connector vibration testing. In particular, Dave discusses the rationale, techniques, and procedures used to perform vibration testing at Samtec.

Dave begins by telling us that connector vibration testing is routinely performed to assess the mechanical and electrical stability and performance of a connector when subjected to the types of vibration that may be encountered during normal use. The type of vibration and the control parameters are dictated by the intended product market.

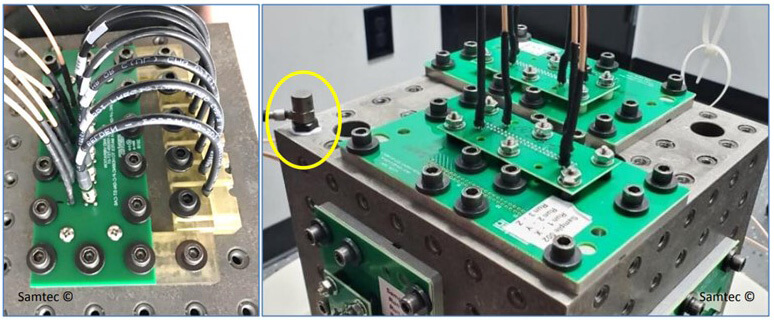

Proper test fixtures and mounting techniques are key to successful test exposure.

The paper includes a definition of vibration (an oscillating mechanical motion), what are the common sources of vibration (speakers, motorized assemblies, solenoids, fans, etc.), and what are the common vibration failures (from cracks and wear, to the microscopic damage of internal components and fretting corrosion). (BTW, there’s a link to Dave’s paper on fretting corrosion at the end of this email.)

Dave next discusses the test itself, focusing on protocols, the importance of proper mounting, why fixtures matter, and the fact that it’s difficult to over-secure the product and PCBs in connector vibration testing.

Next Dave gives four reasons for why we perform vibration testing, and he discusses the five types of connector vibration testing that Samtec can perform in our lab. BTW, random vibration and swept sine are the most frequently requested, in that order.

What are common pass/fail criteria? Answers include physical/mechanical damage, electrical degradation, and optical signal degradation.

What kind of test system is commonly used in connector vibration testing? A typical closed-loop vibration system monitors the vibration level close to the sample and adjusts the system accordingly to maintain proper test conditions. Dave shares an illustration of such a system.

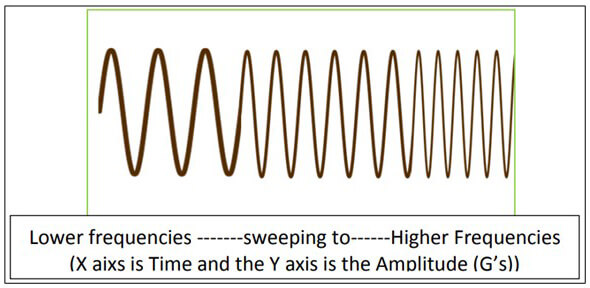

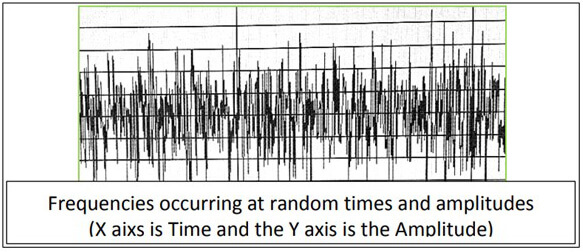

Since swept sine and random vibration are the two most frequently requested tests, Dave compares and contrasts the two.

The modified sine wave below represents the concept of a pure sinusoidal motion of varying/swept frequency, typically from 10 to 1,000 Hz, and the most common level run at Samtec is 15 G PEAK.

The random vibration, time domain waveform below shows varying amplitudes and frequencies, from 50 to 2,000 Hz, and the most common level run at Samtec is 7.56 grms.

The two most common monitoring tests are Low Level Contact Resistance (LLCR) and Low Nano-Second Event Detection (sometimes referred to as discontinuity monitoring). LLCR assesses resistance stability by comparing the contact resistance measured before and after vibration exposure.

Event Detection monitors the dynamic electrical stability to a pre-specified requirement, such as “X” ohm for a duration of “Y” nS.

Here’s a link to Dave’s “Shaken, Not Stirred” whitepaper on connector vibration testing, if you want to read it in its entirety. And here are some other blogs based on Dave’s white papers:

- Creepage and Clearance and Why We Care About It

- Connector Voltage and Power Rating 101

- How Samtec Uses A Scanning Electron Microscope to Ensure Quality Connectors

- Fretting Over Fretting Corrosion

- Interconnect Susceptibility To Galvanic Corrosion

And here’s a few other blogs about shock and vibration:

Leave a Reply