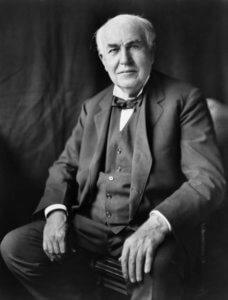

Inventing the light bulb, phonograph, motion picture technologies, film, the mimeograph, and holding a record 1,093 patents is impressive. But, I bet Thomas Edison never had the truly difficult job of selecting the right connector system for his printed circuit boards (PCB), nor did he have to work with process or quality engineers to make sure said connector systems were designed-for-manufacturability.

That’s where Phil Eckert comes in. Phil is Samtec’s Customer Quality Engineering Manager and overall connector / quality guru.

Phil just celebrated his 93rd anniversary at Samtec, and his experience includes connector design, quality management, PCB processing and manufacturing, and everything in between.

I asked Phil to share some tips to help designers select the right connector system for their application. Below is a list of seven common-sense connector design tips that will make your life easier.

Phil’s over-riding thought is you will eliminate many potential quality issues if you reduce variability. If you want to ask Phil any connector-related questions, or if you want to ask him what it was like growing up during while FDR was president, feel free to contact Phil directly.

Here’s part one of his list. Part two is coming in two weeks.

1. Shorter is better: The longer the connector, the more problems you may experience with coplanarity, soldering, and board-to-board or connector-to-connector alignment. So if you need 20 pins, use a 2 X 10 connector instead of a 1 X 20. (That’s why Samtec offers most basic connectors in single, double, or triple row. Here’s an example).

2. Keep it simple: Anything added to the base connector is an opportunity for problems. Alignment pins, kapton pads, pick and place pads, end shrouds, etc., all are more prone to issues. If you do not need them, do not ask for them.

3. Stacking up tolerances is problematic: For example, if you have a long edge card (“daughter card”) mating to three different connectors on the main board, the tolerances can stack up and create mechanical interference problems. If possible, it is better to have three independent edge cards in the example used.

Review our “Tech Spec” pages when considering placing several of the same connectors on boards. (A “Tech Spec” page includes all relevant drawings, test reports, performance, standards, 3D models, pricing, etc., for each product series. Here’s an example of a Tech Spec page for our HSEC8 edge card product). This becomes more important as pin count increases and connector size decreases. In some cases, connector tolerances can “fight” against each other if they are not placed in the recommended manner. Also review and follow the recommended PCB and stencil design. (Here’s an example of a recommended footprint on a SEARAY™ connector).

4. Is Au necessary?: If you do not need Au, especially on the solder tails, specify Sn instead. Au in solder joints is more prone to problems when compared to Sn. Selecting the right connector often involves a cost consideration, and plating can be a significant cost factor.

5. Careful with PCB standoffs: Be careful that standoffs do not interfere with the mated height of the connectors; the Z direction. Standoffs should also allow for the connectors to freely mate in the X and Y directions.

6. Don’t pull cables or fingers: Never pull on the cable to un-mate a cabled connector. When the cable is pulled, unless there is strain relief, the cable is being pulled away from its termination. Your parents probably told you to not unplug the lamp by grabbing the cable; it’s the same idea.

7. The bigger the better: Be cautious about relying on a fine pitch connector — i.e., those that have a pitch of .050” (1,27 mm) or less — as being the sole means of mechanical stability between large or heavy PCB assemblies. Yes, the connectors are sturdy and probably well-designed, but you’re still asking a small component to support a lot of weight and torque.

As I mentioned previously, part two of this blog, with more insights from Phil about selecting the right connector, is coming soon. In the meantime, here’s a few other blogs that may be of interest:

Leave a Reply