When they hear the phrase connectors for medical applications, most electronics types think of some type of I/O interconnect to accommodate the cable interfaces on handheld devices. Push-pull cable products, circular cable assemblies, and wire-to-board solder cup headers and sockets usually come to mind.

The medical electronics industry is one of Samtec’s largest customer segments. But unlike most other suppliers, Samtec’s most popular connectors for medical applications are all high data rate products. In this blog we’ll take a quick look at three Samtec connector products commonly used in medical electronics.

High-Speed Cable Assemblies

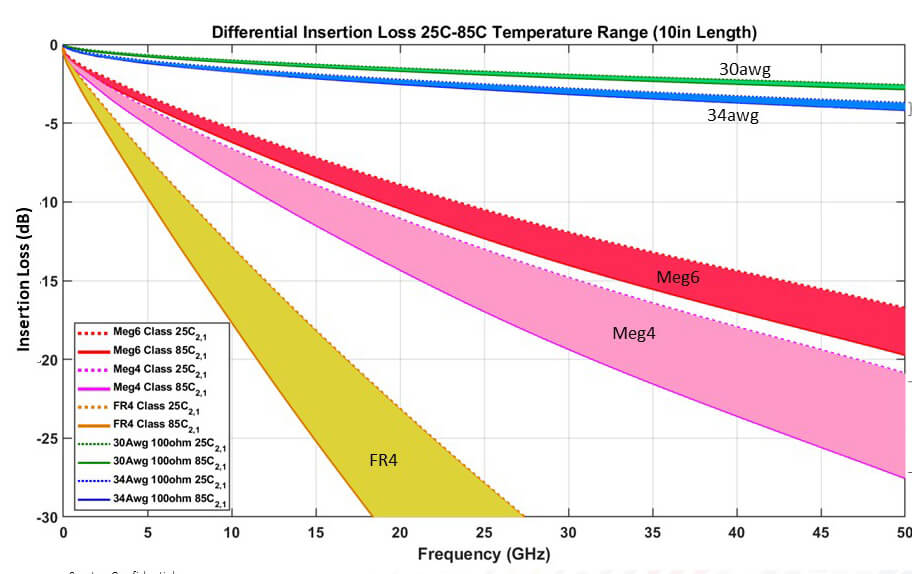

High-speed cable assemblies are most frequently used for medical imaging (MRIs, CT/CAT Scans, PET Scans, and Ultrasound) and rapid diagnostics. High-speed cable assemblies are available with micro coax and twinax cable for both single-ended and differential applications. Most designers incorporate a Samtec Flyover® cable system; this extends signal reach and density to achieve next generation speeds by routing signals through ultra-low skew cable instead of through a lossy PCB.

As bandwidth requirements increase, effectively managing heat and routing signals through lossy PCBs, vias and other components have become complex challenges. Samtec Flyover cable systems break the constraints of traditional signaling substrate and hardware offerings, resulting in a cost-effective, high-performance and heat efficient answer to the challenges of 112 Gbps bandwidths and beyond.

Optical Cable Assemblies

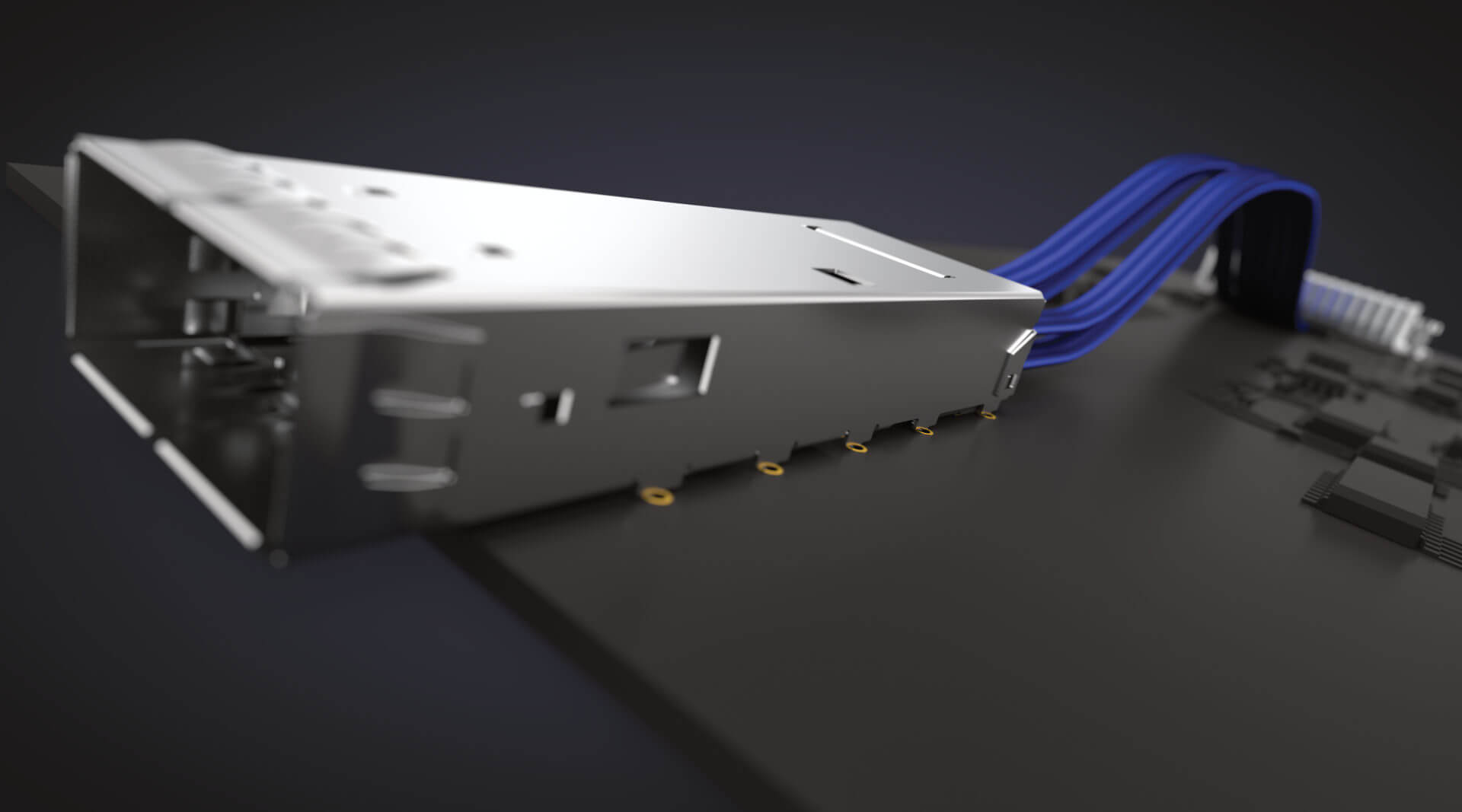

Optical cable assemblies were originally of interest to medical designers because they are non-magnetic. But they have become popular because of the data rates (obviously), and because the connector’s miniature footprint. The FireFly™ optical cable system allows for greater density and closer proximity to the IC, enabling chip-to-chip, board-to-board, on-board, and system-to-system connectivity. The data rates achieved with optics allow designers to incorporate future functionality upgrades without having to redesign their boards.

Both high-speed cable assemblies and optical cable assemblies are also popular in rapid diagnostics equipment. Same day results for Covid-19 testing, as well as upcoming demand for in-store testing equipment (i.e., self-testing for Covid-19 and other infections at your local drugstore) are two examples of this market. Other example include DNA Sequencing and infectious disease analysis.

High-Density Arrays, Micro High-Speed Edge Card Connectors

High-density, open pin-field arrays (SEARAY™) are a favorite with designers because they allow maximum routing and grounding flexibility, are available in a variety of design options (different pin counts, a variety of stack heights, etc.), and incorporate the rugged Edge Rate® contact system. Like high-speed cable assemblies and optical cable systems, SEARAY is frequently designed into high-speed imaging devices, as well as rapid diagnostics.

Micro pitch, high-speed edge card connectors (HSEC8) are popular in portable medical equipment, including ultrasounds, pulse oximetry sensors, smart AEDs, etc.

Here’s a few other blogs that may be of interest to you:

Leave a Reply