A new high-speed, high-density Samtec Flyover® cable system extends signal reach to achieve next-gen speeds and improves thermal management. Andy Shrout, Samtec’s High-Speed Cable Product Manager, walks us through this demonstration, originally shown at DesignCon 2022.

High-speed channels route directly off the chip package substrate to the front panel, through Samtec Eye Speed® Ultra-Low Skew Twinax. The channels don’t route through BGAs and multi-layer PCBs.

This demo also shows how cable management can be optimized for an even distribution of the thermal load. The path from chip package to front panel I/O is a typical architecture like we see in data center and telecom infrastructure, or HPCs, to name a few applications.

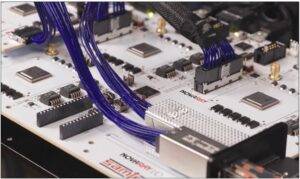

Let’s take a closer look at the design. We see 32 low-profile, Samtec Si-Fly™ cable assemblies, each with 16 differential pairs. This is 512 lanes, and 51.2 TB of aggregate data.

The extremely low 3.8 mm profile allows Si-Fly to be placed adjacent to the IC package and under heat sinks, or as shown here, directly on the substrate, for design flexibility.

From the Si-Fly interconnects, the signals route through 34 AWG Samtec Eye Speed® ultra-low skew twinax cable, to the front panel. These cables range from 12” to 20” (30 to 51 cm) in length.

Samtec’s proprietary co-extruded twinax cable technology eliminates the performance limitations and variability of individually extruded dielectric twinax cabling. It improves signal integrity, bandwidth, and reach, for high-performance system architectures.

The cables terminate to 16 NovaRay® I/O high-density panel mount cable systems. NovaRay I/O has the industry’s highest aggregate data rate, 3,584 Gbps PAM4, shown here with 32 diff pairs per port.

The Si-Fly to NovaRay I/O Flyover cable system is rated at 112 Gbps PAM4.

In an active demonstration, also at DesignCon, a Si-Fly to NovaRay I/O Flyover system, with eight connectors and two and a half meters of twinax cable, achieved a pre-FEC BER of e-7.

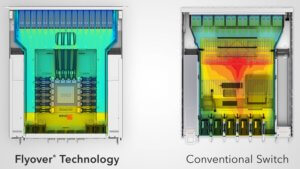

Samtec Flyover cable systems allow the ASIC, FPGA, or device to be located in the center of the tray, creating more symmetry in the system, and resulting in more laminar airflow. This gives us a lower ASIC inlet temperature.

Here’s an interview with Samtec’s Aaron Tucker on cable management, thermal management, system design strategies, etc. If this topic interests you, you can learn more about it by reading this interview..

You can contact us for more information on thermal management, and how Samtec Flyover cable systems can extend signal reach and lower losses to help you achieve next-gen speeds.

Leave a Reply