I don’t watch much television, but when I do, I am captivated by some of the products advertised. Some of them are hilarious, but I don’t think they were meant to elicit that reaction. The products in many of these ads are “products looking for a solution.” I mean, who would buy a hamburger grill that runs on your car exhaust, umbrellas for your shoes, or diet water?

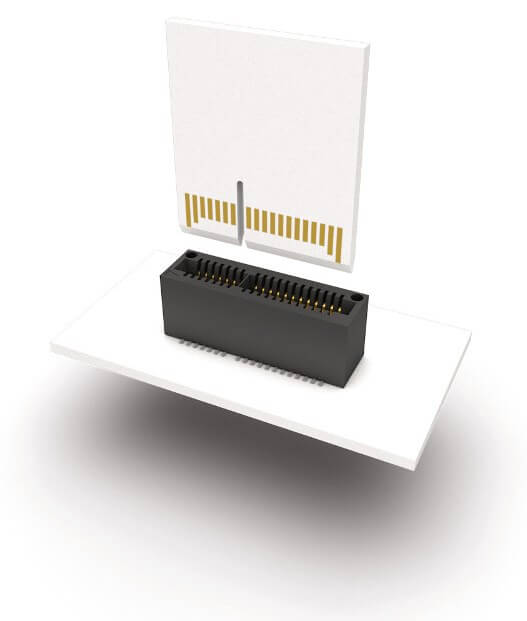

I’m also not always a fan of “new and improved” products, unless the improvement has merit. Having said that, Samtec is introducing a “kind-of” new version of our popular HSEC8 connector. When I say “kind-of” new, I mean we are introducing a new option designed to accept blunt edge cards, which saves money and processes in pcb manufacturing.

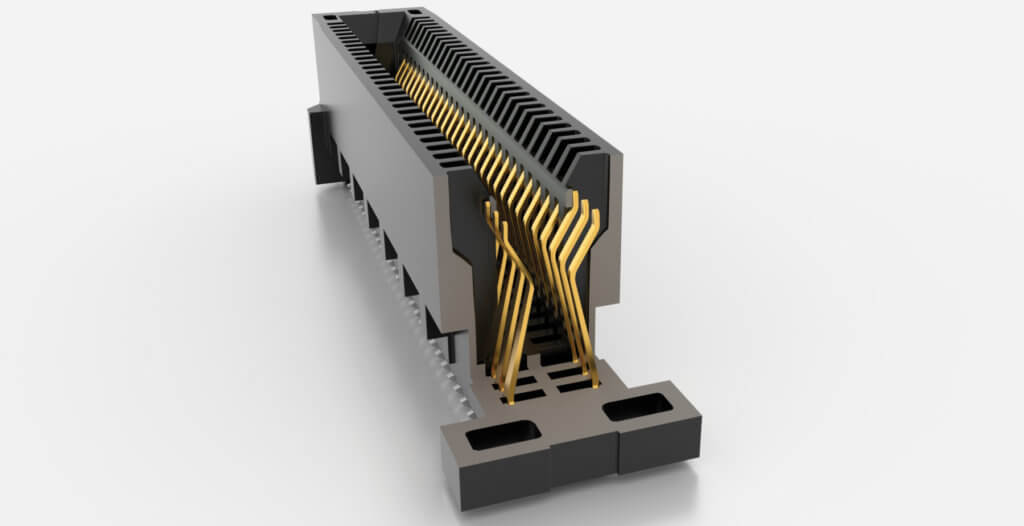

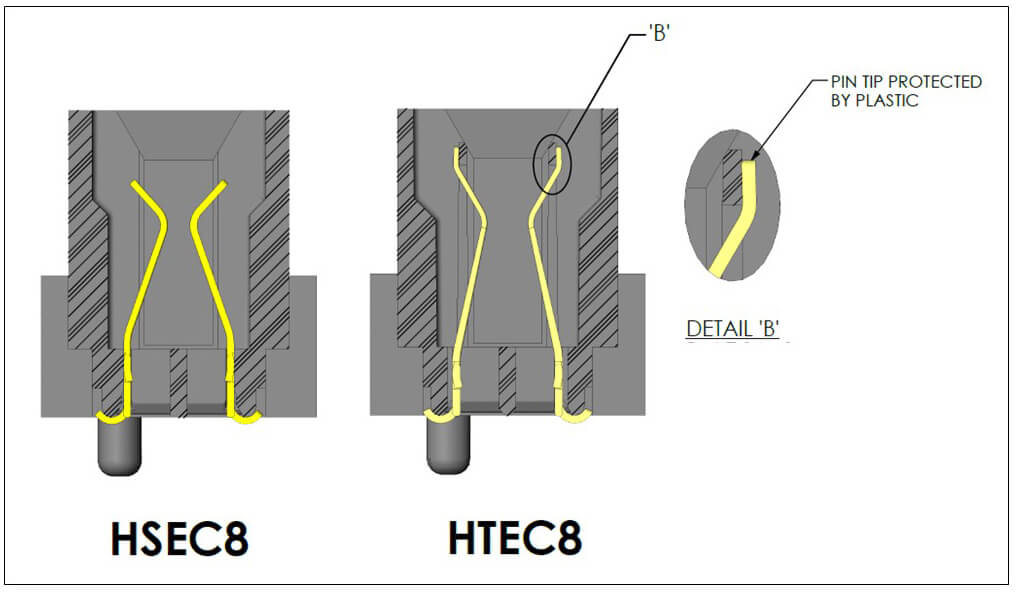

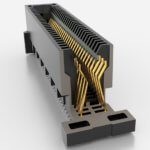

HSEC8 is a micro pitch edge card socket that incorporates our rugged, higher-cycle Edge Rate® contact. The Edge Rate contact system in the HSEC8 is also high speed; the contact geometry is designed, simulated, and optimized for 50 and 100 ohm systems. Oh yeah, and there’s all kinds of design flexibility.

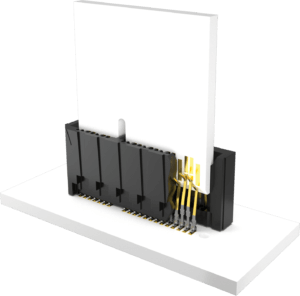

So how do we “kind-of” improve on that? The new HTEC8 — a variation of the HSEC8 socket — is designed to allow more lead-in for the mating PCB. Specifically, the tips of the HTEC8 contacts are completely hidden behind the chamfered entry in the plastic insulator (body). This is especially helpful when the mating PCB has a blunt edge. Blunt-edge PCBs cost less than PCBs with chamfered edges. Also, HTEC8 can be used if a designer just wants to be sure because his manufacturing or assembly process has less-than-ideal assembly or PCB mating circumstances.

The HTEC8 is footprint compatible to the HSEC8 and has similar electro-mechanical and electrical specifications.

HTEC8 is available from 40 – 200 positions, is PCI Express Gen 4 compatible, accepts 1.60 mm thick PCBs, and is available with optional weld tabs for additional mechanical strength on the board. It is RoHS compliant, lead-free solderable, and UL recognized.

Other links that may be of interest:

Leave a Reply