Samtec’s SEARAY™ high density, high-speed array interconnect is now available in a right angle, press-fit design.

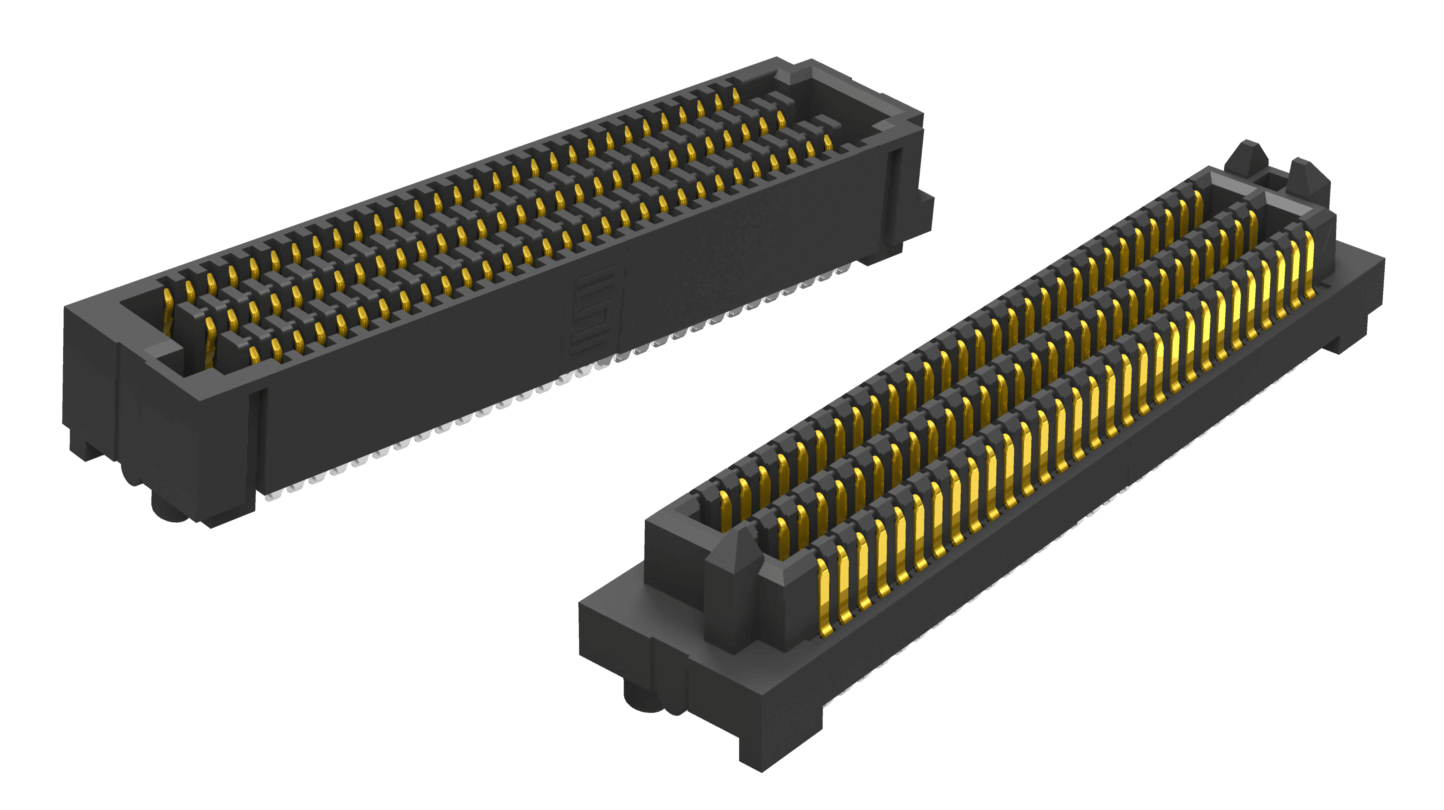

SEARAY™

The SEARAY™ high speed array system is a 1.27 mm pitch open pin field array for maximum grounding and routing flexibility. It is available with up to 500 I/Os, and the rugged Edge Rate® contact has low insertion and withdrawal forces to simplify pcb handling. SEARAY® is an Extended Life Product™ (ELP) and has passed 10 year mixed flowing gas (MFG) and high mating cycle (250 to 2,500) testing.

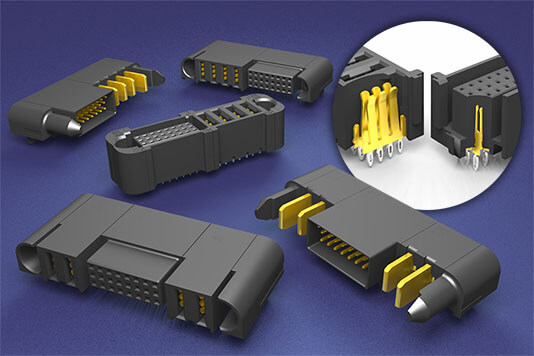

Press Fit Right Angle

The new SEAFP –RA series press-fit receptacle mates with SEAM terminal arrays in either press fit or SMT solder charge terminations. Press fit tails are obviously a standard in the backplane world. Advantages of press fit tails, while well-documented, include avoiding thermal exposure to the backplane by eliminating exposure to heat in SMT reflow or wave soldering processes, retention, the flexibility to terminate interconnects on either side of the backplane, eliminating the risks of shorts and cold solder joints, consistent electrical performance, and you can eliminate the hassles of lead-free solder.

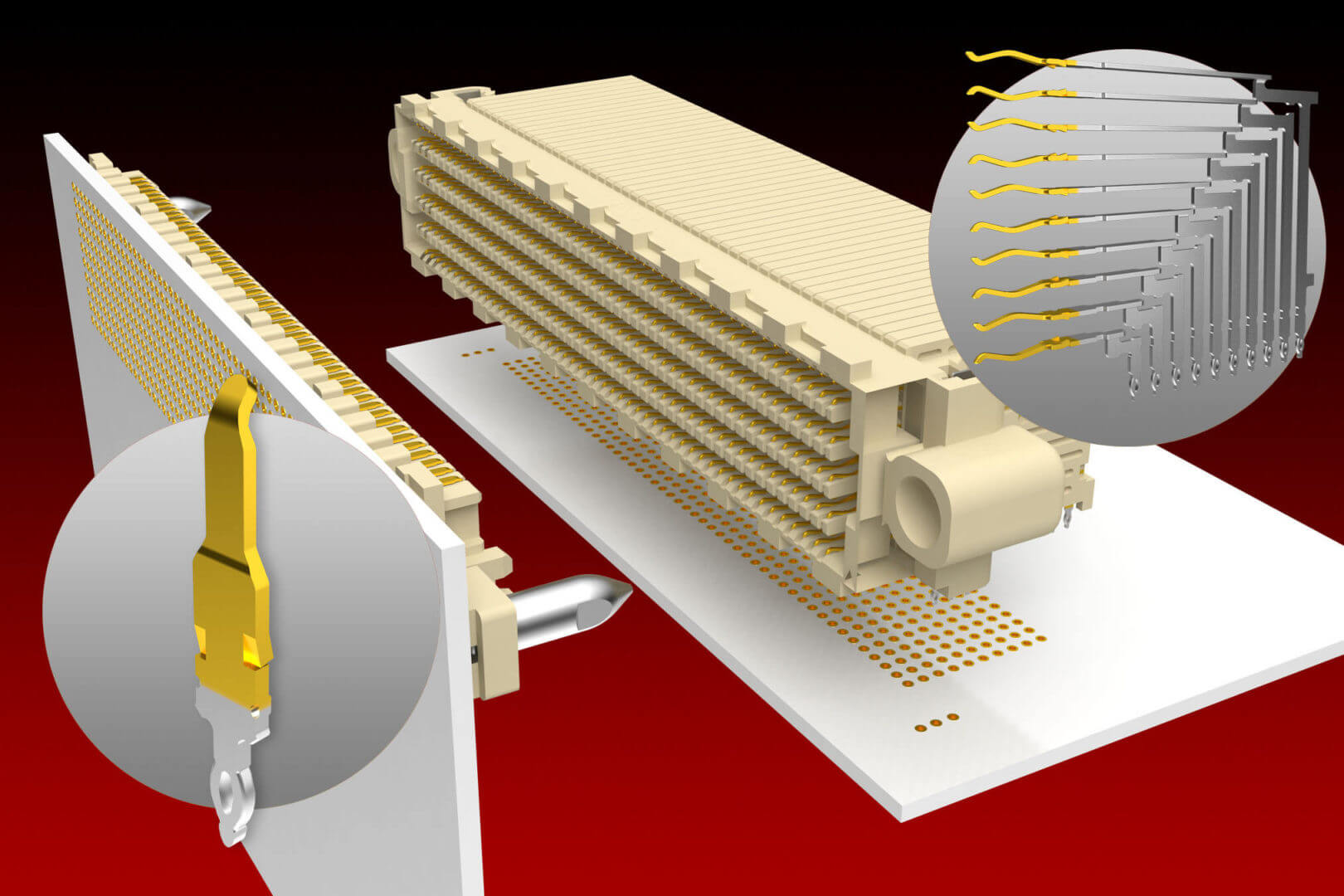

Micro Backplane

While not a backplane connector per se (if you want a true backplane check out ExaMAX®) press fit SEARAY™ is a popular micro backplane interconnect. Micro backplane are high density, high speed, micro pitch interconnects available in right angle and edge mount configurations.

Optional guide post holes aid in proper alignment when mating with SEARAY™ terminal arrays, which are also available in right angle and press fit terminations. The Edge Rate® contact system increases cycle life and minimizes the effects of broadside coupling, which decreases crosstalk for superior signal integrity performance and impedance control. This rugged contact system is also less prone to damage when “zippered” during unmating. SEARAY™ interconnects are also available with tin-lead or lead-free solder charge terminations for ease of processing.