Straight from DesignCon 2023, Kevin Burt, Samtec’s Director of Happiness, walks us through a proof-of-concept for an on-package, or near-package, linear direct drive electrical channel that gives us a 100-meter link at 112 Gbps.

These links could be used in mid-board optical and copper designs using Samtec Flyover® cable assemblies or high-speed mezzanine connector sets, as well as for full-channel front-panel and back-panel cable applications.

A Multilane Pattern Generator generates a 112 Gbps PAM4 signal, which travels through 6” of low-loss coax cable to a Samtec Bulls Eye®, BE70A test point system. This board is made of Tachyon® 100G.

The signals then travel through another 1” of PCB trace, to a Macom 4 X 112 Gbps PAM4 laser driver which drives a VCSEL that converts the electrical signal into optical.

After traveling over 100 meters of OM4 fiber, it is received at a photodiode and Macom Transimpedance Amplifier converting the signal back to electrical. This then travels to a second Bulls Eye connector, and back to the error detector.

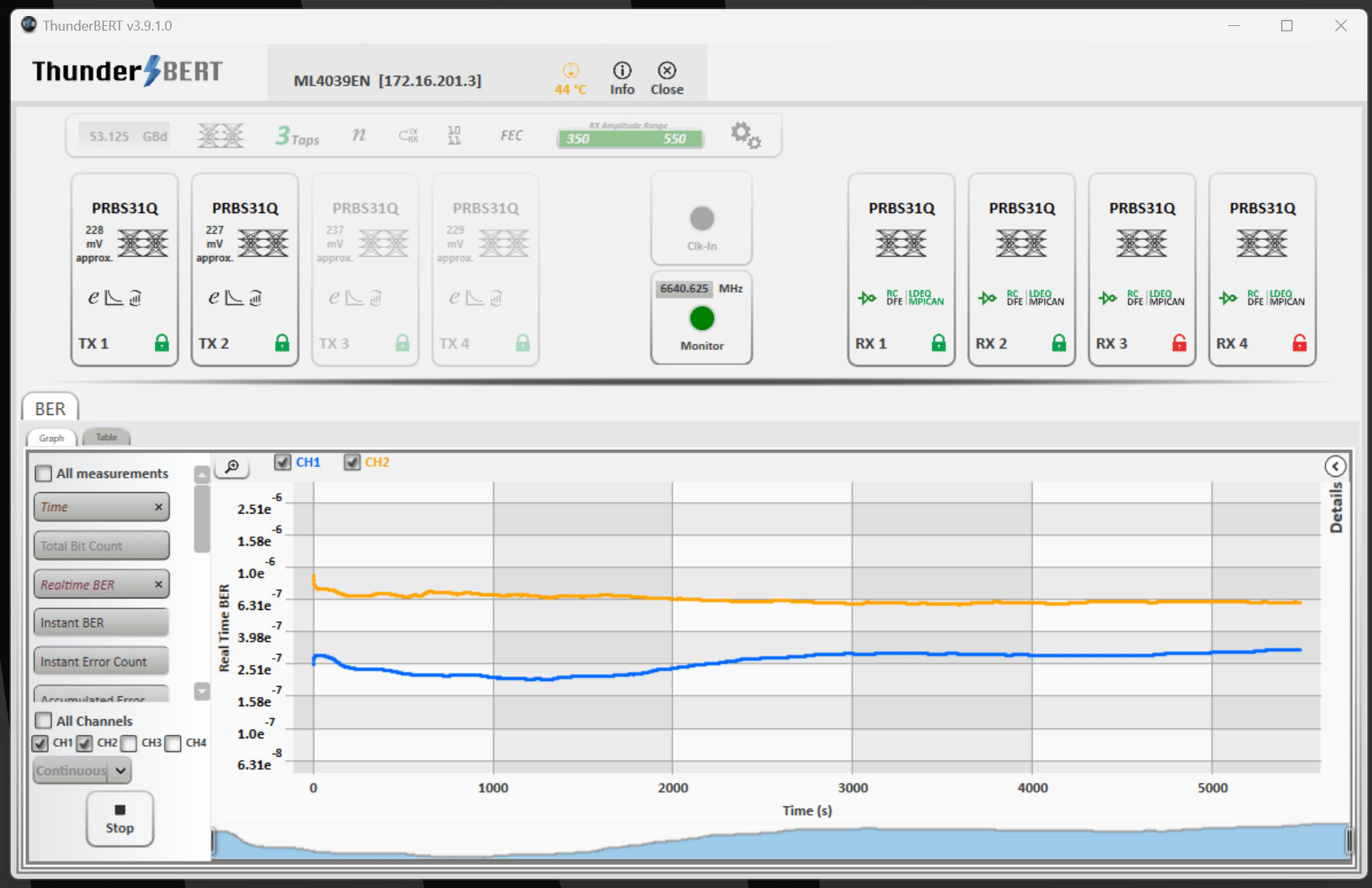

Looking at the performance, we see the BER on two channels is better than 1e-7, and it’s stable over time. We are not seeing burst or dribble errors; it’s going to give the performance with forward error correction (FEC) that designers want for their systems.

There are many benefits to a linear direct drive:

When compared to today’s co-packaged solutions, it gives the network equipment manufacturer (NEM) far more flexibility in their system. It allows the choice of cost-effective copper or high-performance optics, and it also allows differentiation of the type of optics used.

This means that the correct optics can be chosen for the reach, resulting in both power and cost savings.

And when compared to a traditional system with pluggable optics, linear direct drive systems eliminate retimers, which significantly reduces costs. For example, a typical 32 QSFP-DD port Ethernet switch containing 256 lanes could see a cost savings of up to $20,000.

In both cases, optical transceiver DSPs are no longer necessary, which can reduce transceiver module costs by up to 50%. Since DSPs consume significant power, removing this need will also reduce the power and corresponding thermal load.

Next-gen 112 G active optical transceiver will consume 20 to 25 watts of power. Removing the DSP and supporting hardware could reduce the power required by 60% per module.

So in addition to the cost savings, the reduction in power and heat results in improved reliability.

If you want to learn more about this Linear Direct Drive approach, contact the Samtec Signal Integrity Group at [email protected].

Leave a Reply