In 1995, I attended a seminar in which the presenter told us that copper was dead.

This sort of statement is not new. The connector market is filled with armchair pundits who predict the demise of everything from D-Subminiature connectors (which are very much alive and kicking) to the V.35 telecommunications connector (which is as dead as the Dodo). This just goes to prove that it is almost impossible to predict the future trends of this industry with any certainty.

Making Predictions

In the seminar, the presenter told us that we were approaching the limits of what copper connections could deliver in terms of speed. He said that 100 Megabits per second (Mbps) was the best we could hope for. After this, the future belonged to fiber optics.

Then, as now, fiber optics are viewed with a certain amount of fear by some engineers. Using fiber optics, and certainly installing optical connectors, is different from the traditional methods familiar to generations of engineers using electrical copper-based connectors. But in 1995, fiber optics offered almost science-fiction-like performance, and we were all just going to have to get used to it.

It is now almost 25 years later, and I recently attended the European Conference on Optical Communication (ECOC) in Dublin. I went to ECOC to take a look at the latest in copper connection technology and to see three Samtec partners demonstrate the latest connector technology.

That may sound crazy – why would I attend a show about fiber to see the latest innovations in copper?

Relying on Fiber

Fiber optics certainly provide the best solution for long-distance data communications. It should not be a surprise to find that the largest physical manifestation of the internet – the subsea cable network – all uses fiber optics to provide the connections on which we now increasingly rely. Current trends including the Internet of Things and Artificial Intelligence will see the demand for data continue to grow.

However, fiber is not the answer to everything. The semiconductors that provide the processing power for the modern world are still electrical, not optical. Semiconductors create the data that must then be transmitted at rocket-ship speeds, and so the need exists for a copper connector that will allow extremely high-speed data to be taken from silicon to silicon, or silicon to fiber.

For decades, the printed circuit board (PCB) has been the primary means of connecting one semiconductor to another. It has long since replaced the old cable connections that provided the backbone of the first generation of electronics. However, one of the features of PCBs is that they become very inefficient when transmitting higher data speeds. This limits their usefulness when it comes to high-speed communications infrastructures.

Back to Cables

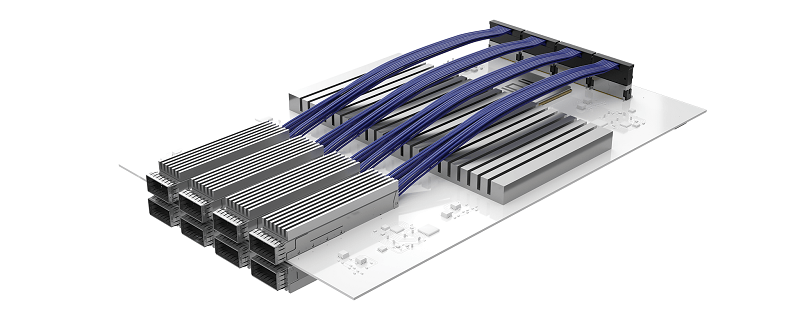

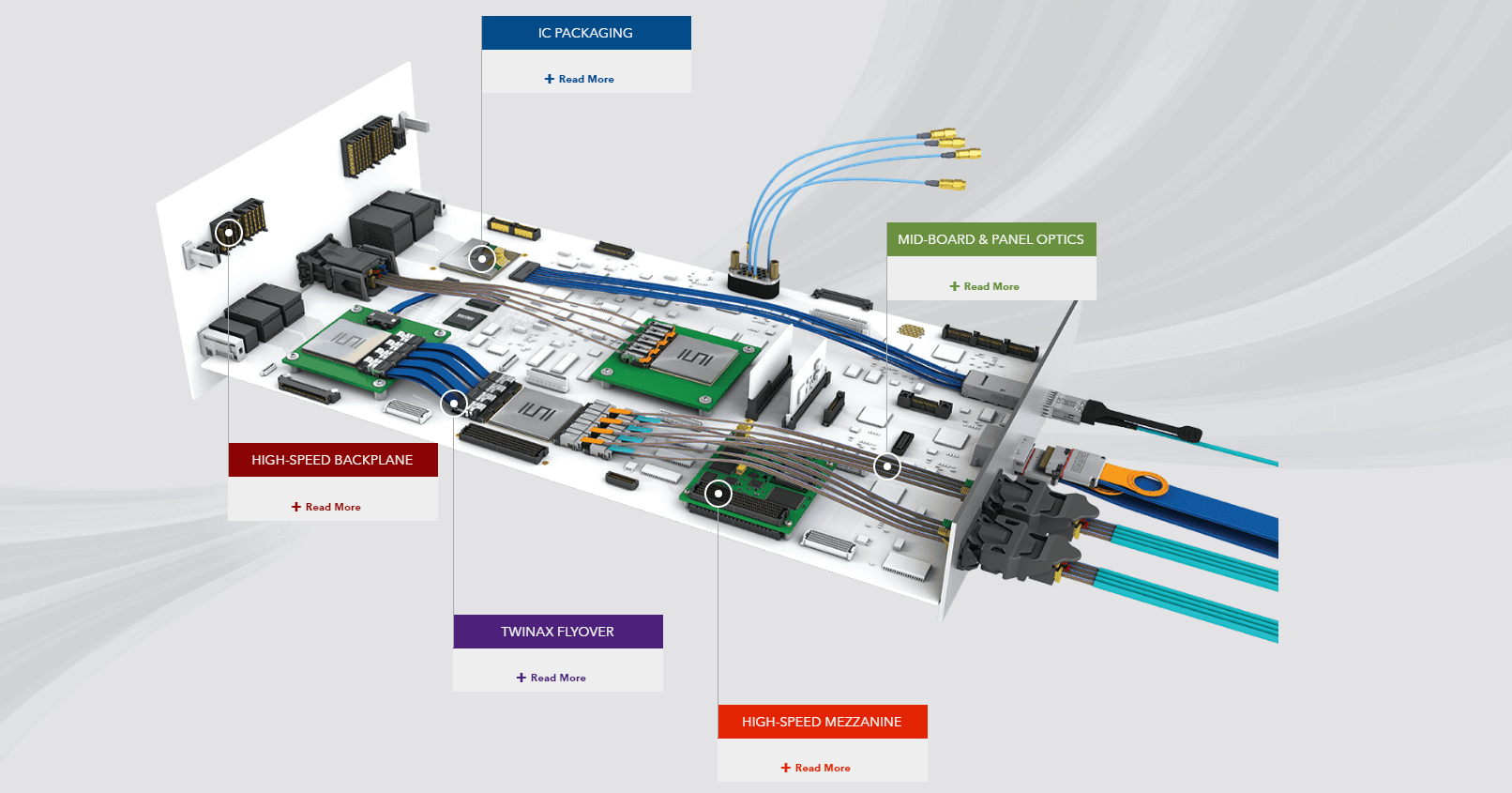

This is why the concept of Flyover® architecture was developed. In chip-to-chip applications that require communication over relatively short distances, such as between two racks, it is considerably more efficient to use cabled connections rather than PCBs. Samtec is creating innovative solutions in this field that are designed to complement the latest developments in silicon technology.

The best way to see these high-speed products in action is to attend a show like ECOC, where manufacturers like eSilicon, Inphi and Credo are able to show their latest developments.

I was particularly impressed by eSilicon, who showed the capabilities of Samtec high-speed cable solutions over a long distance. Using the Samtec ExaMAX® connector, eSilicon demonstrated a practical example of a rack-to-rack application which achieved a staggering combined data rate of 2.2 Terabits per second over a 7 metre cable.

112 Gigabits per Second

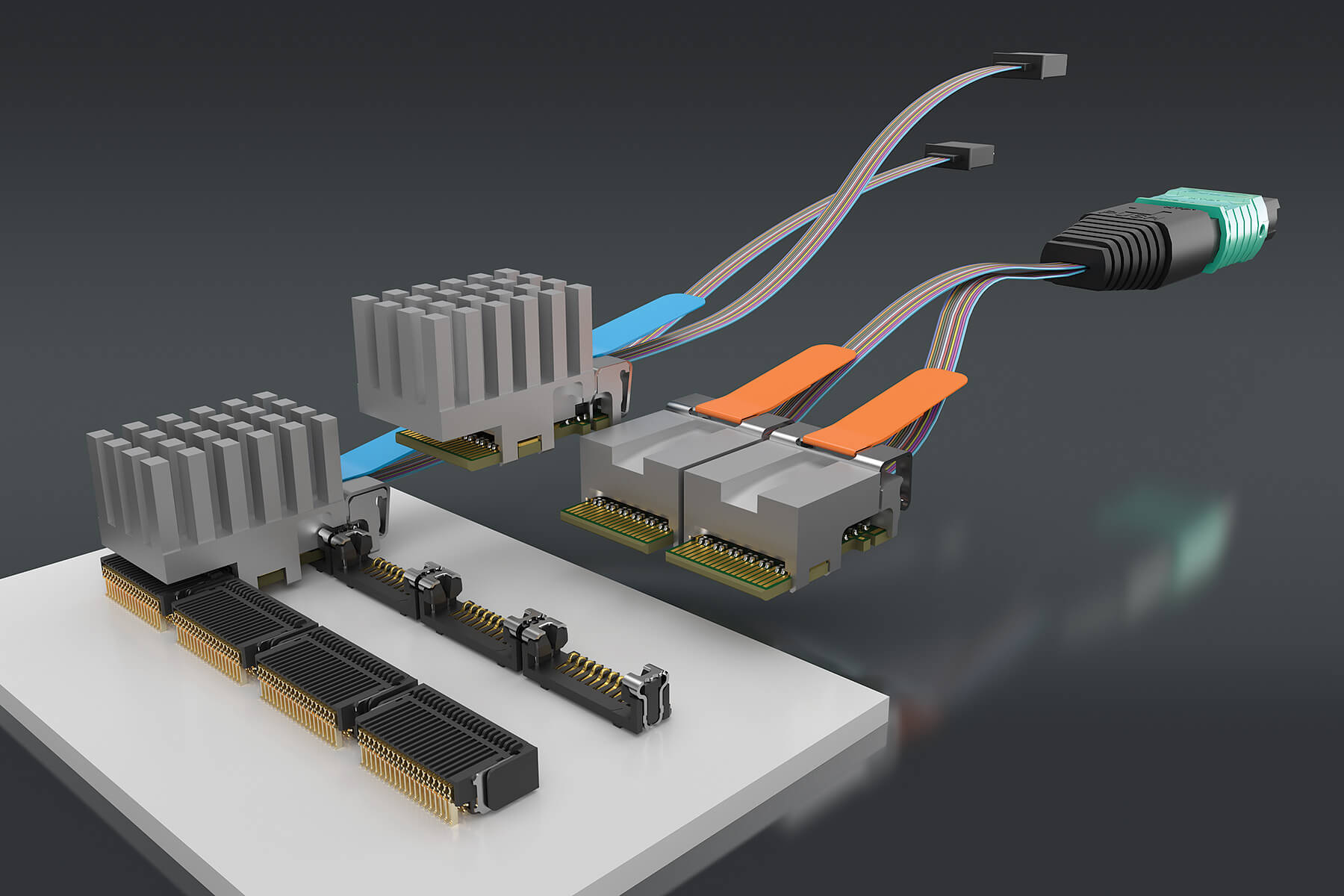

Another impressive demonstration could be found on the Inphi booth. Their latest test silicon is generating data at 112 Gbps, and Samtec have provided systems that allow transmission of these data speeds over copper. Using a combination of NovaRay™ and ExaMAX®, Inphi silicon represents the solution for the next generation of data center infrastructure.

Another product that is used in the Inphi demonstration is the Flyover® QSFP deliver up to 56 Gbps PAM4 performance per lane using micro twinax cable.

Samtec products are not only found using copper technology. Samtec is blurring the lines between copper and fiber systems with the FireFly™ Micro Flyover System™. FireFly lets the user choose between a copper or optical interface using the same connector system, providing great flexibility.

It would appear that predictions concerning the demise of copper were premature. Although there is clearly a case for a combined copper and fiber strategy when it comes to high-speed data, innovations in the world of electrical connectors like the Flyover system mean that copper is going to be with us for a long time to come.

I’ll remember that next time I’m asked for a prediction about connectors.

Re: FireFly lets the user choose between a “copper of optical” interface using the same connector system, providing great flexibility. I think you mean “copper or optical”. Also interesting- how you mix fiber” and “fibre”. Great article though, I was in the business when fiber optics came along and it was viewed with much trepidation!

Hi Ron,

Thanks for your sharp eyes. It doesn’t matter how many times an article gets proof-read, or by how many people – there’s always one typo that sneaks through!

As for the fibre/fiber question, that one is my fault. I’m a Brit, so my habit would be to spell the word as fibre. Anyway, I think we’ve fixed it all now.

Thanks for your comments. You are right, fiber is still viewed as alien by lots of engineers!