Many of our Samtec blogs focus on high-speed, high-bandwidth, cutting-edge connector applications rather than simple board stacking connectors. This makes sense because Signal Integrity is a critical issue for many of our customers, and because it’s a more flashy, attention-grabbing, sexy topic. And yes, I did just use the word “sexy” to describe a connector application. And yes, I do need a vacation …

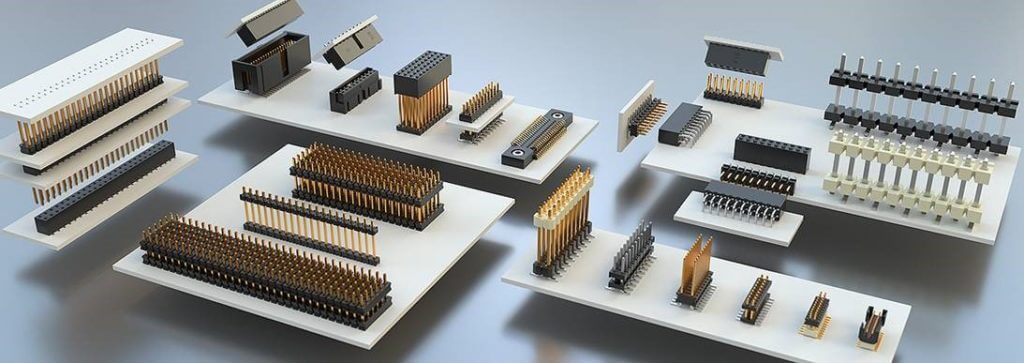

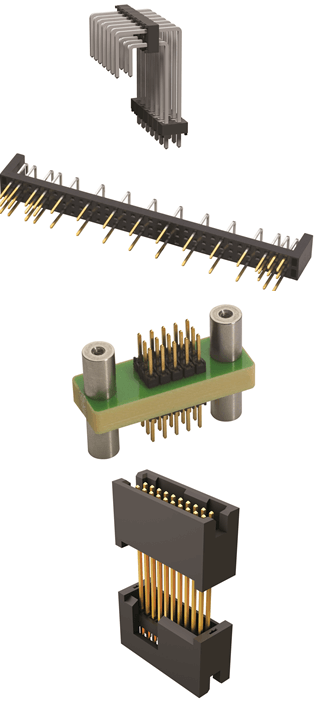

Having said that, two-piece, standard pitch (2.54, 2.00, 1.27 mm centerline), pin-and-socket board stacking connectors are one of our biggest selling product categories. We call these “Flexible Stacking” products, and they are used by just about every type of customer known to Samtec: industrial, telecom, Datacom, medical, computers and peripherals, instrumentation, test and measurement, mil/aero, and automotive, among others.

Flex Stacking (that’s what the in-crowd at Samtec calls “Flexible Stacking”) is most popular among our industrial customers. Common applications for board stacking connectors include factory automation, embedded computing, robotics, monitoring, vision systems, measurement, metering, motion and process controls, safety and security, to name a few.

Here are five important things to know about Samtec Flex Stacking connectors that make them great for industrial applications. But thinking it through, these things make them great for any application.

Flexibility in Board Stacking Connectors

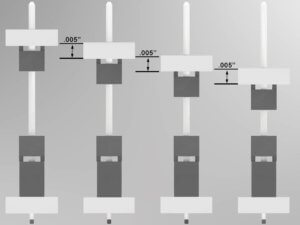

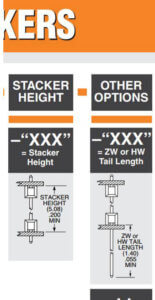

Arguably our strongest capability is what we call “Flex Stack.” Flex Stack is the ability to move the plastic insulator (body) up and down the terminal pin in increments of .005″ (0.127 mm) on header strips and dual-body stackers. If you need a .360″ stack height, we’ve got it. Ditto .365,” .370,” .375,” and so on, and so on.

You specify the post height and/or stacking height — the distance between the two plastic bodies — in the standard Samtec part number. To the right is a picture of part of a Samtec catalog page. See the “XXX” — that’s where you specify the exact stack height you are need.

This allows designers to order a custom stack height for a board stacking connectors with:

• a standard part number

• no minimum order size

• no long lead times

• and no tooling or NRE charges.

The Flex Stacking capability is available on .200″, .156″, .100,” 2 mm, .050″, .050″ x .100″, 1 mm, and 0.80 mm pitch terminal strips.

Pass-Through

Samtec has a variety of contact systems in our socket strips which gives designers the flexibility to do some pretty creative board stacking.

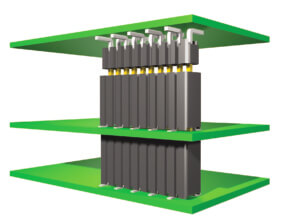

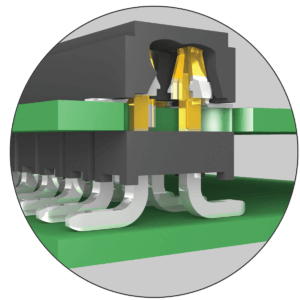

For example, Samtec’s Tiger Claw™ contact is a low-profile, dual-wipe, pass-through contact. The Tiger Claw contact is available in 1.00, 1.27, 2.00, and 2.54 mm pitch socket strips. The profile of the SMT version is usually 2.29 mm (.090”). But more importantly for today’s discussion, Tiger Claw is a pass-through contact, meaning the terminal strip pin can pass through the bottom and/or top of the socket strip.

Pass-through sockets give designers the ability to connect three boards. A common design has a terminal strip with longer pins on the top PCB. These pins pass through the Tiger Claw contacts in the socket, and through non-plated through-holes in the middle PCB. These same terminal pins then mate with a second socket on the bottom (third) board.

Pass-through sockets also allow bottom-entry, pass-through applications, where the terminal strip pin (on the bottom PCB) passes up through the bottom of the top PCB and into the contact. This is used for low profile board stacking, or if the application requires certain components to be on the top side of the PCB.

Elevated to Low Profile

Many designers are faced with the challenge of limited PCB real estate – not only the overall size of the finished good, but also its profile. We all know that most electronics continue to trend smaller and thinner. Many designers of industrial products don’t face the same size constraints, and in some instances, they need a greater separation between PCBs for airflow, to accommodate taller components, or for easier access to the PCB, to name a few reasons.

Guess what – Samtec offers a full line of elevated board stacking systems, on a variety of centerlines, pin counts, and configurations. By elevated I mean any PCB stacking application over .500” (12.7 mm). Here’s a few examples of elevated products: ESW, ZW, TW, ESQT, but there’s many more.

Variety

Samtec has more ways to connect two or more boards together than any other connector supplier. For brevity’s sake, here’s a partial list that shows our wide variety of design attributes:

- Usually available in pin counts from 1-50 pins per row

- Vertical, right angle, and coplanar (horizontal) designs

- Through-hole, SMT, press-fit, even mixed technology

- Single and double row strips are most common, but they go up to six rows

- Variety of centerlines: 5.08 mm (.200”), 1.27 (.100”), 2.00 (.0787”), 1.27 (.050”), 1.00 (0.39”

- Shrouding, alignment and polarization options, plating options

Modifications

Most designers shy away from using modified or custom interconnects, mostly due to concerns about price, availability, and sourcing. But there are times when you can’t find a standard product that works in your design, and you have to consider using a modified or custom interconnect.

Samtec has the ability and willingness to design and build modified and custom interconnects, from simple to complex. Nearly 25% of Samtec sales are modified and custom products, mostly because we have a team of dedicated ASP (Application Specific Product) engineers and technicians, combined with our in-house quick-turn manufacturing capabilities, which provide unparalleled design and service flexibility. To prove my point, for years Samtec has been ranked #1 in turnaround time to design a new connector.

Examples of frequently requested “Express ASPs” include:

- Unusual angles or bends (anything besides the usual right angle / 90ᵒ)

- Multiple bends or angles on the same pin

- Extended right angles

- Multiple polarization

- Mix and match different pin lengths

- Modified footprints

- Alignment and mounting options

- Special platings

- Screen printing part numbers, identifying marks on the connector

- Stacked plastic insulators for custom stack heights

- Headers with ferrites

- Incorporating FR4 substrates

- Special cables and wiring – grounds, shielding, bands

By the way, Samtec has literally millions of ways to connect two or more PCBs. Check out the online Solutionator tool. It makes it very easy to find the best mated socket and terminal set, based on your design requirements.

If you have any questions about Samtec products for use in industrial applications, contact the Applications Support Group.

Leave a Reply