It is always good to learn from someone who knows more than you! I recently had the chance to speak to our very own Istvan Novak about power integrity (PI), and it was very illuminating. Istvan is one of the key figures in the understanding of PI, and we are proud to have this award-winning engineer as part of the Samtec family.

At Samtec, we often talk about Signal Integrity (SI) and our work to develop new high-speed connector solutions for the latest applications. As I write this, Samtec is very active in the world of 112Gbps PAM4 signaling but we are also talking regularly about 224 Gbps PAM4. During a recent interview with Samtec’s Director of Product Management, Keith Guetig, I asked for a brief description of SI. He told me that, “SI means more signal, less noise.”

Hopefully, you will understand that SI is a huge topic, and reducing it to just a few words ignores the detail of high-speed signal design. However, in my efforts to understand SI more fully, these are words that help me enormously. But while we talk about SI regularly, we less frequently talk about Power Integrity (PI).

Understanding Power Integrity

The problem is that, while SI is well-defined with a wealth of information available to engineers, PI requirements and best practices are less defined. It is up to the designer to determine how to manage their own PI needs.

The goal of PI is to provide power to the system within acceptable limits. Key to this goal is the power distribution network (PDN), which is defined as the entire path of current from the power supply all the way to the consumer. This means minimizing the voltage fluctuation across the consumer, in spite of fluctuating current demanded by the consumer.

This variation or ripple is induced by dynamic current introduced by the consumer, and is often created by switching. This can reduce the voltage or create spikes, either of which affects the quality of the power supply as it reaches the consumer. The use of decoupling capacitors can reduce the effect of these variations, and the closer that these capacitors can be placed to the consumer, the more effective they can be.

However, in common with signal integrity, the medium over which power is transmitted also has a major impact on the PI of a power network. Connectors are a key component in this battle to provide clean power.

When looking to provide a PDN that maximizes PI, designers must consider both the series resistance and the series inductance of the components. When it comes to selecting a suitable connector, we frequently look at contact resistance as a key indicator of its performance. However, inductance is not so familiar to many of us. In general, series resistance will influence the DC drop while series inductance will determine the AC transient noise.

We can apply a generalization in which a higher overall inductance will require a greater number of decoupling capacitors. It is possible to reduce the inductance of a connector by altering its geometry – the arrangement of power contacts in relation to each other. But as the challenges of PI are less well understood, there is less information available to help the designer.

Connectors and Power Integrity

While there are a few guidelines that will help, there is no single rule that is true for all applications. For example, we could ask whether it is better to employ a connector with a few large contacts, each carrying higher currents or a larger number of smaller contacts in which the power is distributed more evenly across the connector. For higher, unregulated input voltages where the system can tolerate greater AC fluctuations, a single larger blade-type contact will be more suitable. A larger contact will be able to carry larger currents at higher voltages, and will therefore minimize the DC losses. However, once the power supply has been regulated, the problem of AC fluctuation becomes more important. In this case, the inductance of the connector will be lower using smaller contacts, using several in parallel to reduce the current transmitted through each.

As a result, the designer must be prepared to ask some important questions when establishing the power requirements of their system. What is the required target output, how low can this be allowed to fall before affecting functionality, and what is the source of any noise that might affect power integrity?

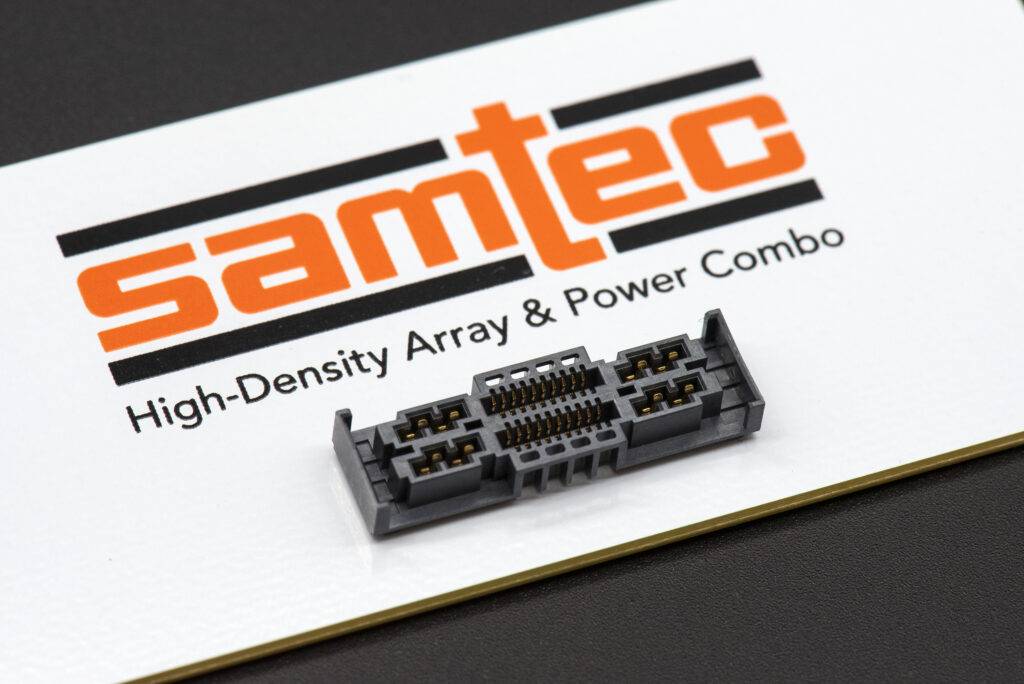

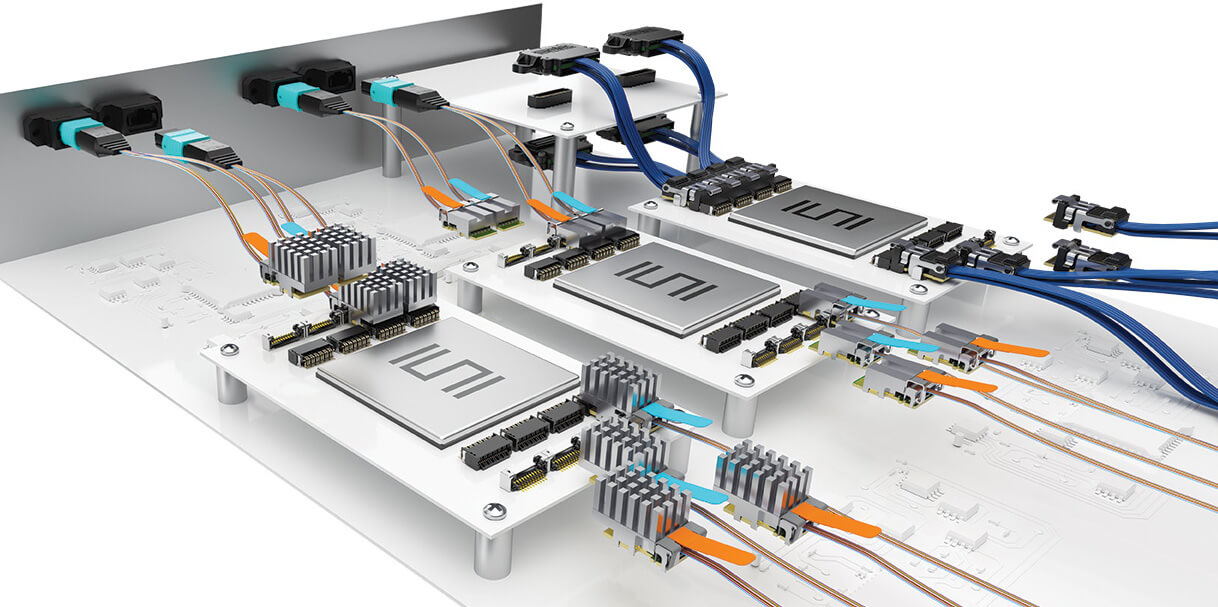

The upcoming Accelerate/mP, also named as UDx. A combination of two well-established connector families, the Accelerate high-speed connector and the UMPx power blade, with one noticeable upgrade: the blades in the power connector are turned in parallel to the connector body. This allows easier and more convenient power routing on the board and better cooling, ultimately raising the maximum allowed current value by 15-20%.

With the emphasis on high-speed communications, it is easy to assume that signal integrity is the only aspect that must be considered. However, a reliable and clean power supply is vital to fast communications. Selecting the right connector geometry, and thus the right connector, plays a huge role in maintaining a clean power supply.

Samtec is exhibiting at DesignCon 2023, and Istvan will be once again sharing his in-depth knowledge of PI. He will host a discussion about the use of power integrity simulators and will be promoting the new edition of his new book, Power Distribution Network Design Methodologies. Come and visit the booth on February 1st between 2:30 pm and 3:00 pm to meet the man himself, and to look at some of the latest Samtec products in use, including Accelerate®, mPOWER®, Si-Fly™, and NovaRay®

Register for DesignCon 2023 today and join us as we fly the flag for Power Integrity!

Leave a Reply