As our blog team was reviewing upcoming topics, I was considering a few possible topics, so put a TBD on the schedule. Before I knew it, the time was drawing near and my list just did not fit as well as I had hoped. I jokingly said I would write about a family experience and put up a slide show of pictures!

The first quarter of most schools is winding down and people are traveling for a Fall Break. Read on if you would like to go on a family vacation with me and how I use some of these experiences to explain to my kids what Samtec does.

Customers and Inspiration are Everywhere: Family Vacation or Not

I recently had the fortune to take a bit of a long weekend with the family down to Disney World for our Fall Break/Family Vacation getaway. There is no shortage of electronics and special effects in that place. I am sure if they let me I could find some Samtec products behind closed panels.

From beginning to end, Disney has many customer interactions. This starts with opening your hotel room with a Bluetooth connection or using an embedded RFID Magic Band to get into the parks or on rides. The number of little RF antennae and sensors embedded everywhere is incredible.

When you start to look at the special effects, props, and experiences that exist around every corner it is amazing to think of just how many wires and connectors are running through every building, set, ride, or sidewalk.

We Make the Things that Enable those Things!

While waiting for the next ride I tend to look for odd things and point them out to my kids. “I think I know how they do that,” I would say as we queue. Sometimes they oblige me and listen, other times they roll their eyes and ask “how much longer,” or “can I get a Mickey pretzel?” To which I respond “We will get there when we get there!” and “NO! eat this granola bar I have been packing around all day!”

I see many High-Speed products running the projections, animations, or data servers connecting the apps to the sensors. For the most part on the rides and experiences, I see a ton of Rugged/Power and Discrete Wire products running the controls, robotics, and lighting.

My boys saved up for well over a year to build their own light saber at Savi’s Workshop. The experience was magical and at that moment they were in another world: becoming a Jedi. Once we got home we took a closer look and noticed the components used were not all as out of this world as we initially thought.

Spoiler Alert! they are not actually powered by the Kyber Crystal nor do they emit some sort of plasma blade. They are however pretty amazing, even if they are only a rigid PCB loaded with over 100 LEDs and wrapped with foam to diffuse the light.

Inspirations for Demos and Displays.

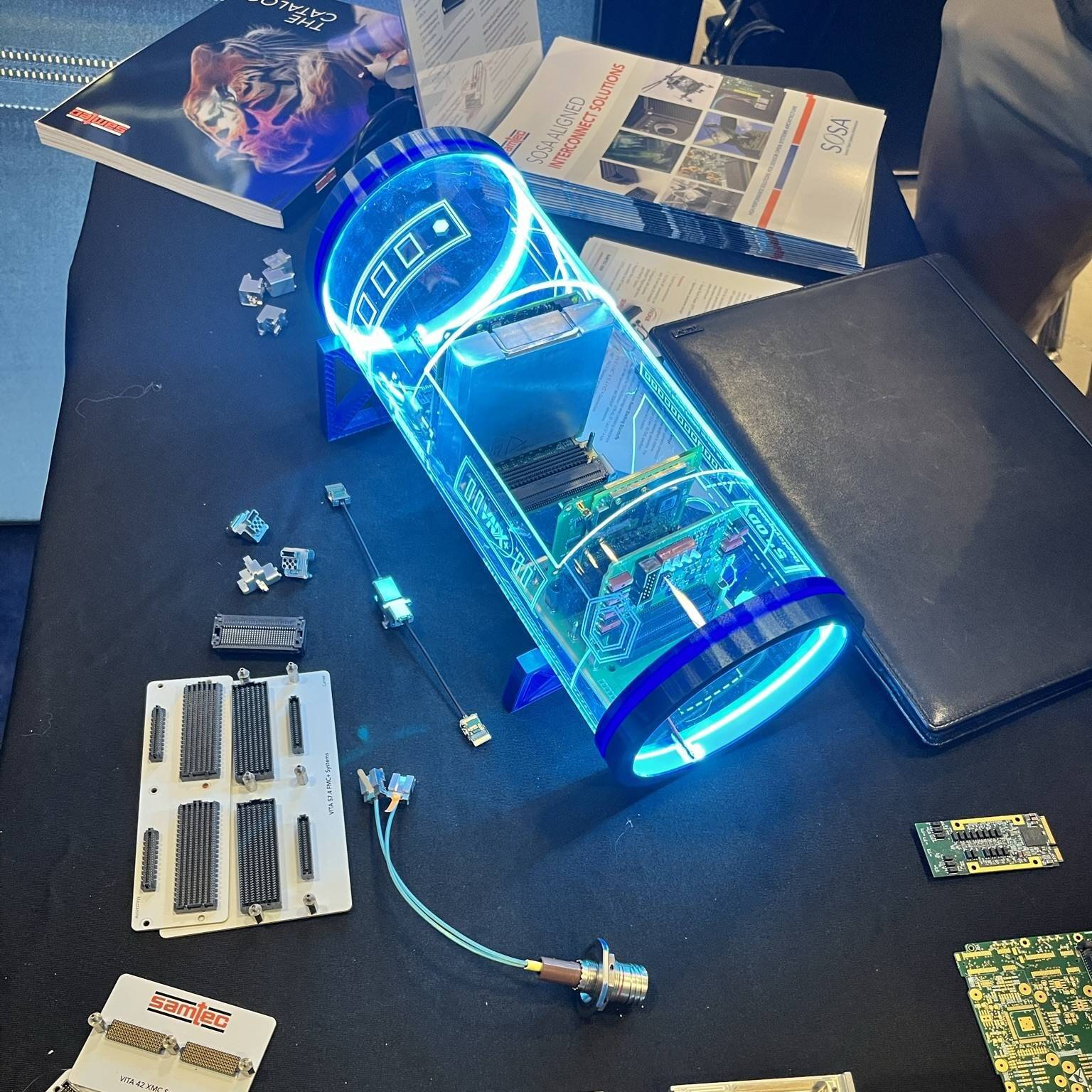

We now have to save up for another three years to go back to Disney. We will relish the memories and inspiration until then. Upon returning I was able to take a few ideas and build a demo for the recent Air Force TIM.

Some of our rugged products could be deployed in round cylindrical pods. The best way to show this new standard is to mount a system in such a way that our customers could easily picture this installed.

The acrylic tube was laser etched with some designs that may be reminiscent of a droid or ship from Star Wars. LED lighting was projected through the edge of the acrylic to make the logos and designs stand out. Customers could then load and unload the embedded system and see how much room they still have to use.

Am I the Only One?

As a self-proclaimed nerd, I hope I am not the only one who constantly thinks about how things work. I like to think that Samtec connectors are behind every screen, controller, or embedded system, family vacation or not.

Do you build products or systems that are not typically seen by the general public? How do you explain to your friends or outsiders what your company does? We would love to hear the best analogy you have used to describe what you do.

Leave a Reply