Our armed forces need to be able to function in some of the most remote and desolate places on earth. Far from conventional infrastructure, and operating over wide areas, the military cannot depend on conventional wired systems or line-of-sight radio, and so rely on satellite communications.

The Value of Satcom

At the same time, the battlefield is a connected space. The machine-to-machine communications that are so fundamental to the Internet of Things (IoT) are becoming vital to military commanders, allowing widely dispersed units to share intelligence and make rapid decisions based on real-time information. Combined arms operations, which see the integration of air, sea and land assets, require this information sharing to be accessible to all participants. This becomes even more important in multinational deployments.

To provide high-speed information sharing in remote locations, the military turns to satellite communications (Satcom) to provide the links vital to operations. Their orbits high above the atmosphere provide satellites with line-of-sight communications without the need for land-based infrastructure and without the blocking effects of high ground or the horizon.

Devices that provide the soldier, sailor or airman with satellite communications need to be constructed to the same standards as other military equipment. Designed to withstand use in harsh environments, these devices need components that are equally capable in tough conditions. They need to withstand both high and low temperatures, provide reliability when subjected to shock and vibration, and ensure the signal integrity that is vital to rapid and accurate communications.

Challenges of Spaceflight

Communication equipment that is destined for use aboard satellites faces a different array of challenges. The launch and deployment of satellites will see them subjected to prolonged acceleration. Once safely in orbit, equipment will be subject to microgravity conditions, extremes of temperature both high and low, and the vacuum of space.

Outgassing is a key concern to designers working with systems that will be used in vacuum conditions. Outgassing is the name given to the gas and vapor that that is released from non-metallic materials when exposed to extreme heat or vacuum conditions. These gases can then condense onto other electronics or even optical surfaces, significantly impairing their capabilities. Designers, therefore, need to ensure that the components selected have been tested to ensure that outgassing is kept to a minimum.

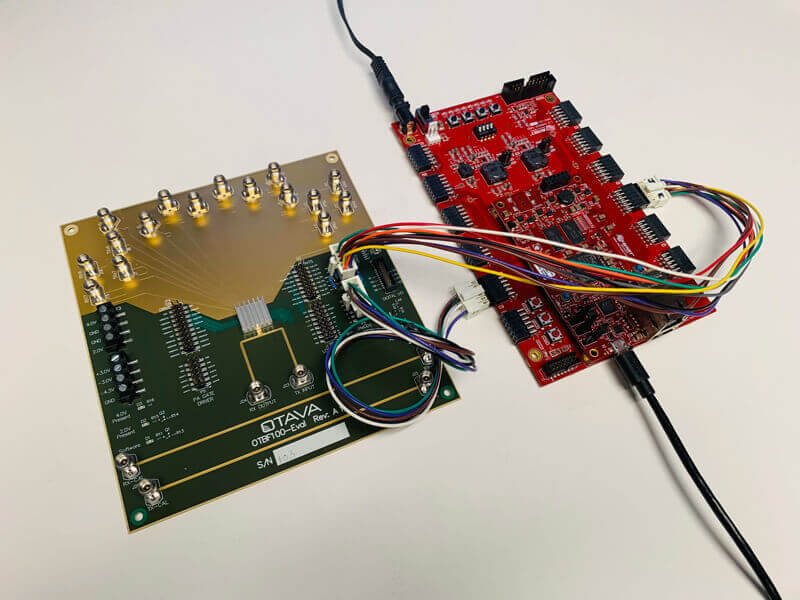

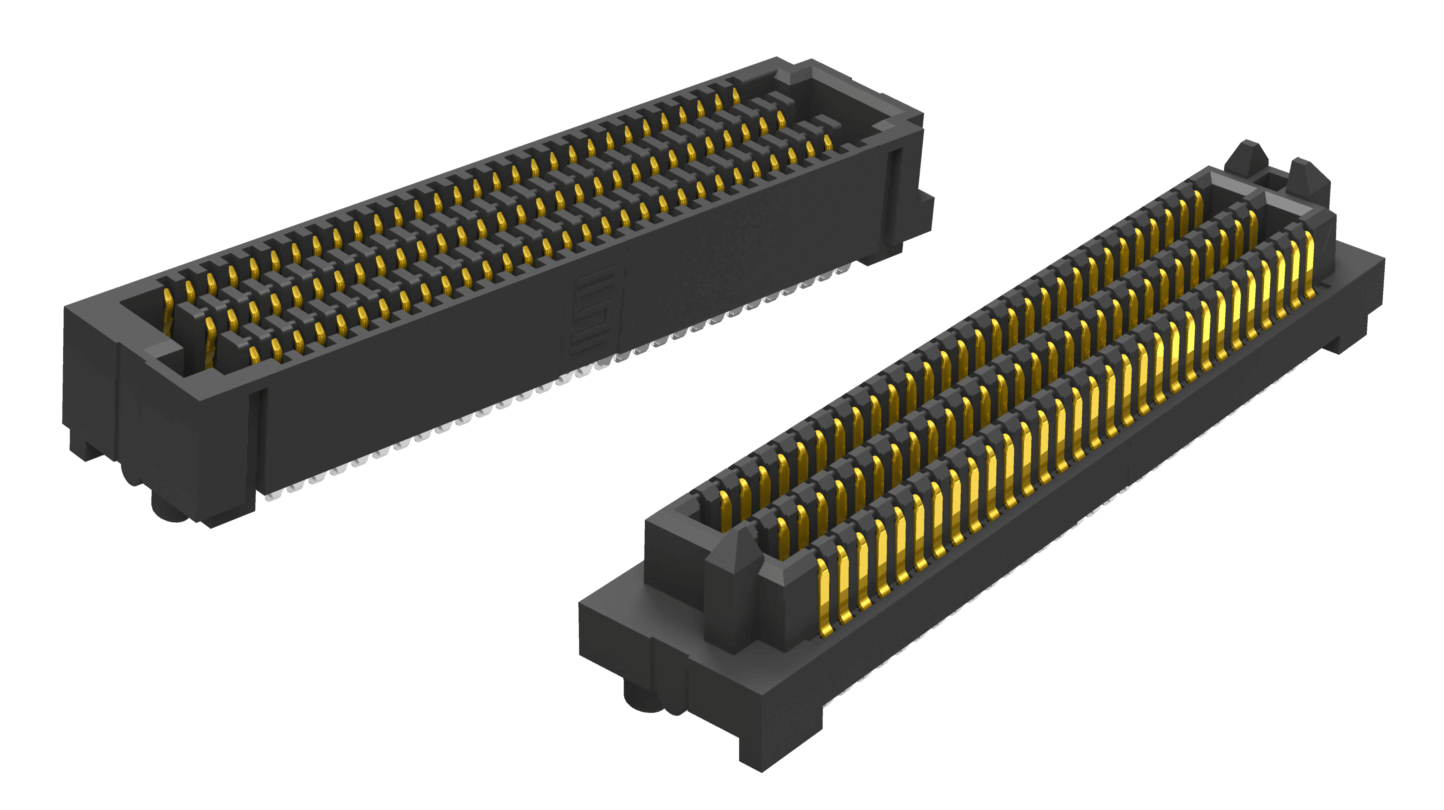

The Severe Environment Testing (SET) program from Samtec takes standard connectors and subjects them to a battery of qualification tests that assure their performance far beyond commercial standards. Tests include thermal aging, mechanical shock with in-test continuity, and electrostatic discharge (ESD). Outgassing is also tested to ensure that The resulting certification provides customers with the confidence to select the right products, secure in the knowledge that Samtec connectors provide superior performance, even in harsh conditions.

Robust Solutions for Satellite Communications

Samtec’s SET products have also been approved for NASA Class D missions that require high-reliability and cost-effective solutions. Suitable for use in low-Earth orbit (LEO) and geostationary-Earth orbit (GEO) applications, Samtec products have been selected for SmallSats, CubeSats, and a number of other space exploration projects.

In the modern age of digital devices, it is easy to forget that wireless transmissions, including satellite communications, use radiofrequency (RF) technology. Samtec boasts a specialist range of precision RF connectors that are designed to provide solutions for frequencies of between 18 GHz and 110 GHz, making them ideal for Satcom applications. Samtec also has market-leading expertise in high-speed board-to-board, cable, and active optic connectivity.

Learn more about Samtec’s capabilities in SATCOM with the dedicated MIL/Aero industry applications page. The Samtec blog is also packed with useful information, including an insight into the latest mmWave technology and a detailed look at outgassing.

Leave a Reply