Design engineers are the heroes of the electronics industry. Responsible for creating everything from cell phones to satellites, it is the creativity of designers that drives the modern world.

Engineers must respond to a specification. This is where the life of a design engineer becomes a little difficult. In an ideal world, a design specification should be clear and detailed, but I’m afraid that sometimes our design engineer might be given instructions that are less than perfect.

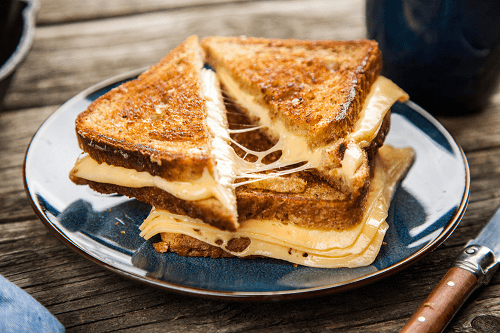

Make me a cheese sandwich!

There is an analogy that might make this problem easier to visualise, and it is called the Engineer’s Cheese Sandwich. It describes a situation where the client presents a design spec to our engineer which says, “Oh, and make me a cheese sandwich!”

Not really a detailed brief, is it? The engineer is now faced with a dilemma. The client has asked for a cheese sandwich, but does the client just want cheese? What kind of bread do they need? Salad? Sauces? The engineer is left to get on with the design based on the vaguest instructions.

A little while later, the time comes for the engineer to present his product to the client. The client has asked for a cheese sandwich, and so the engineer has created just that – a piece of cheese wrapped in two pieces of plain, white bread. The client looks for a moment, thinks, and then says “Where are the pickles? And the lettuce? Oh, and I wanted rye bread. And…”

Suddenly, the engineer has to completely redesign his product at short notice, all because the client was unclear with his instructions. Lucky for us, redesigning a cheese sandwich is a relatively simple task – adding pickles, lettuce, even the rye bread is easy.

The last-minute redesign

To illustrate my point, we need to take this analogy and translate it into the electronics industry. The design engineer has produced the best product possible with what little information he was given, and it does not match up with the image that the client has in his head.

The engineer has already laid out the PCB, created the mechanical design, obtained samples and created the prototype. To redesign at this late stage will cause a lot of problems, especially if the deadlines are tight.

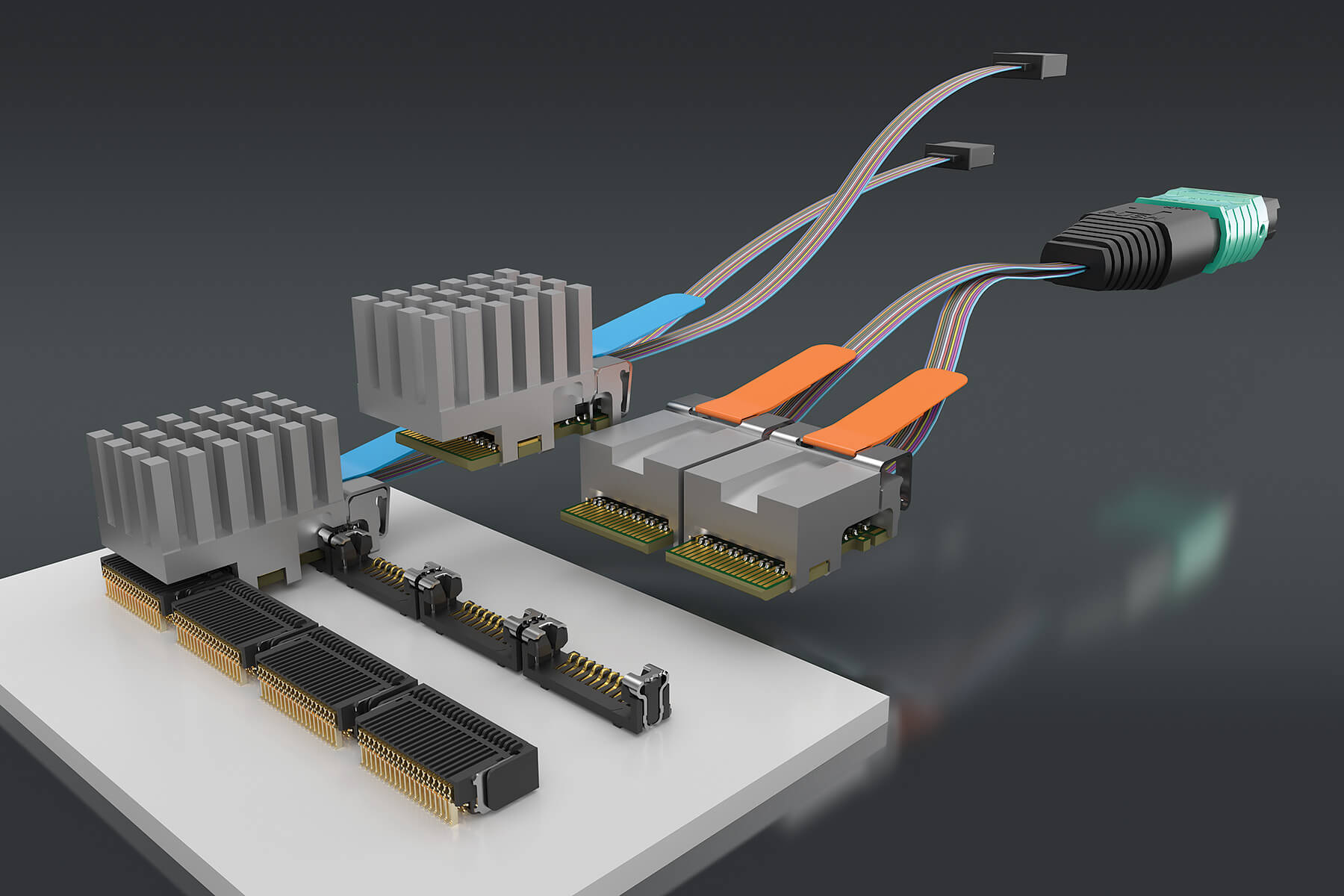

There are those times when to redesign seems all but impossible, and you need to dig deep to find the solution. At those times, you need someone in your corner, someone who can help you be the superhero. Samtec understands your dilemma and has established tools, services, and an infrastructure to help you dig deep.

Fear not, help is at hand…

When it comes to creating the seemingly impossible, Samtec has become known as the “save the day” company. Samtec has built its reputation in the electronics industry by being a genuine solution provider. On-line tools and responsive service allow the customer to configure connectors from a huge range of options, making it possible to find precisely the connector that is needed for your “impossible” application.

“So what?” you may ask. Many connector companies offer configuration tools for customers. What makes Samtec different is their ability to deliver? Using state-of-the-art, rapid manufacturing techniques, the connector that did not even exist 20 minutes before can be made and shipped overnight.

This is truly revolutionary. In a marketplace that is seemingly driven by availability, Samtec is a company that does not hold shelves and shelves of stock. But what Samtec does stock is the expertise, passion and service that allows the engineer to become the superhero, deliver the impossible, and save the day.

After all, who doesn’t like being the hero every now and then?