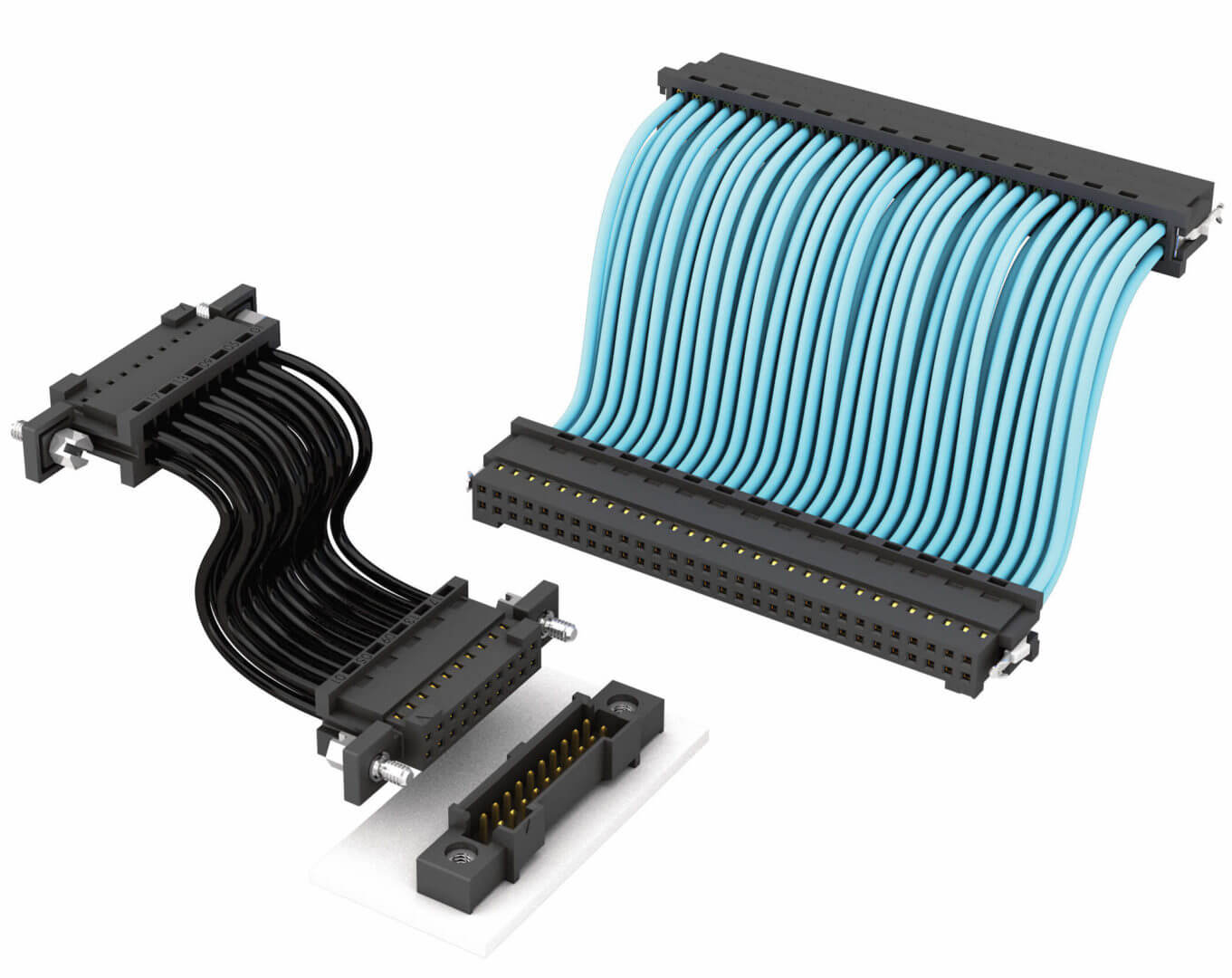

Samtec’s new generation of micro pitch discrete wire cable assemblies – 0.80, 1.00, and 1.27 mm pitch – meet the challenge of electronics devices getting smaller and denser.

Speaking of discrete wire, did I mention that 36% of Samtec discrete wire systems are modified and custom products? What type of modified products are designers asking for, and why? Glad you asked!

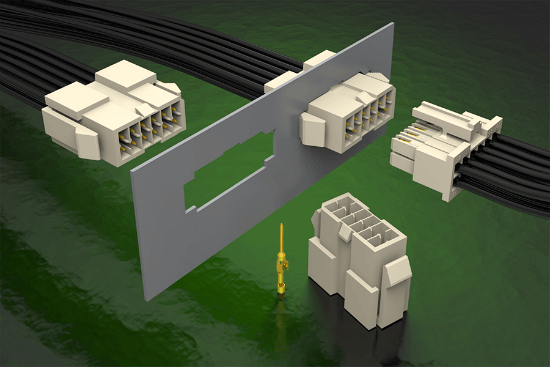

Below is a summary of some of our most frequently requested discrete wire cable assemblies. All of these are pretty easy modifications to our existing standard product line:

Most Requested Discrete Wire Cable Assemblies

Breakout To Smaller Positions: Many discrete wire assemblies breakout from a higher pin count connector to several smaller position connectors. Breakout assemblies provide greater pcb design and routing flexibility. Breakout connectors are common in industrial applications where one main PCB frequently interfaces with several smaller cards.

Color Coded: Color-coded cable is frequently requested; it is almost always used to identify the wire to a position on the connector and pcb. Most of these assemblies are single-ended.

Mixing Cable AWGs: Using two or more wire sizes in one cable assembly allows designers to route signal and power through the same connector. This design can save board space, and it can allow the designer to use fewer connectors. It is most popular on 2.54 mm pitch connectors, because those contact systems accept a wide range of wire gauges, from 20 to 30 AWG.

Twisted Pairs: Of course these are used for isolation, to minimize electrical interference. Multiple twist ratios in an assembly are common because each pair performs at a different frequency.

Jacket / Tubing: Jackets and tubing around the wires are used for a variety of reasons. Some of the more common reasons are:

- protect the wires, usually from heat, or from making contact with a component that needs to be isolated

- cable management and organization; cables may need to be positioned to not interfere with other pcbs, or allow room for a technician to access the system

- lack of clutter, general cleanliness

Ferrites: Ferrites placed around the wires suppress high frequency interference (EMI). Many connector manufacturers prefer to use ferrites that they can readily purchase, instead of using ferrites supplied by their customer.

Custom Labeling: Labels are used to identify virtually anything, including cable end number, the EOEM’s part number, a date code, a lot code, provide safety information (e.g., positive and negative), print rev, etc.

Change Connector Pitch: A common example is switching from 2.54 pitch to 2.00 mm pitch. Perhaps the most common application is a designer needs to connect their pcb to a pcb or device from another supplier. They may design a smaller pitch termination on their pcb to save real estate.

Creepage and Clearance: We frequently pull pins between—in other words, selectively populate – the plastic insulator to meet creepage and clearance requirements.

Ring Terminals, Battery Clips: These terminations are used for power applications, and include terminating cable end 2 to barrel crimps like ring terminals, spades, quick connects, etc.

I/O, RJ 45: We can terminate solid strand and multi-strand wires.

Of course the possibilities are endless.

The point is, 25% of Samtec’s total sales are modified and custom products. Samtec has been rated #1 in willingness to design custom (and modified) products, and in turnaround time of those designs. We have systems in place to make it as easy, quick and affordable as possible to design an interconnect system to meet your specific needs. Contact us and let us know how we can help.

Additional Resources:

- Discrete Wire Cable Products

- Micro Discrete Wire Application Design Guide

- Contact the Application Support Group (questions about any Samtec product)

- Contact the Application Specific Product Group (custom and modified products)