Next-gen, high-performance Test and Measurement platforms support faster data rates than current solutions. Prevailing devices communicate over copper interfaces in standard form factors and traditional bench instrument applications.

At increased data rates, signal integrity concerns over copper cable assemblies and connectors limit the reach and interoperability of systems. The new Optical Data Interface (ODI) is a new high-speed interface standard for advanced instrumentation and embedded systems.

ODI enables higher data rates over longer distances. It increases interoperability in an open system by connecting a fiber-optic data link between two devices regardless of functionality.

ODI is based on a standard optical connector that can be placed anywhere on any device. It defines a highly functional and expandable physical layer. Key specifications include:

- 12-lane multimode optics

- 12.5/14.1 Gbps Data Rates

- Interlaken Protocol

- Flow Control

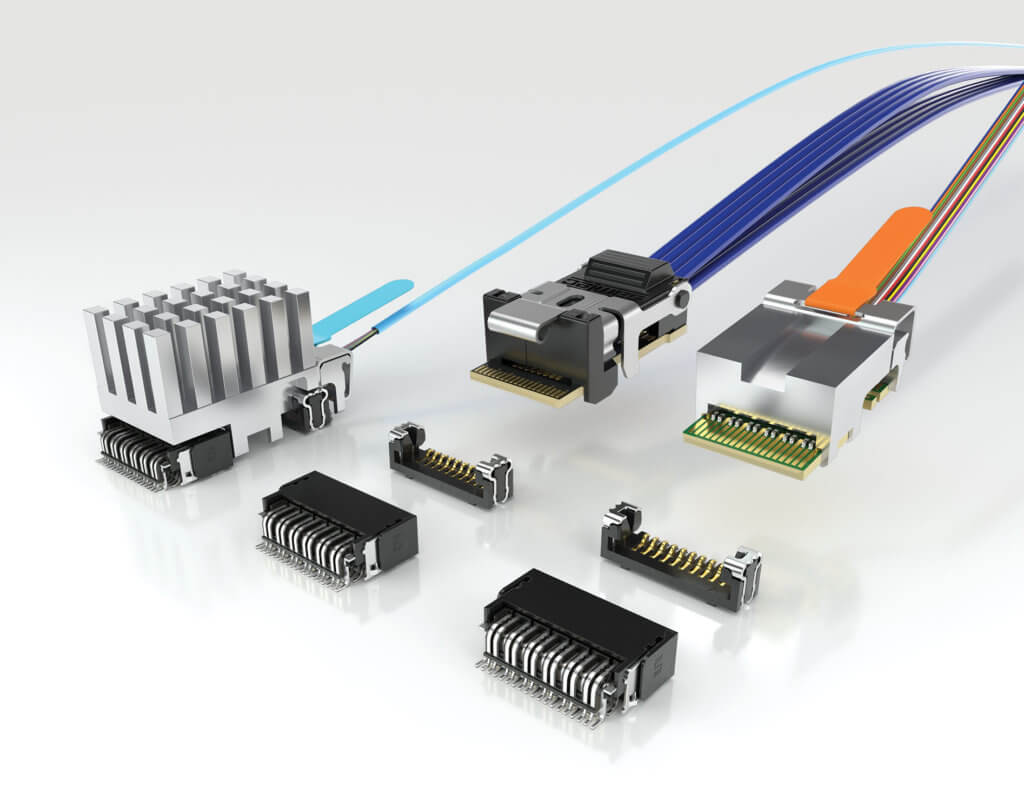

Samtec FireFly™ Micro Flyover System™

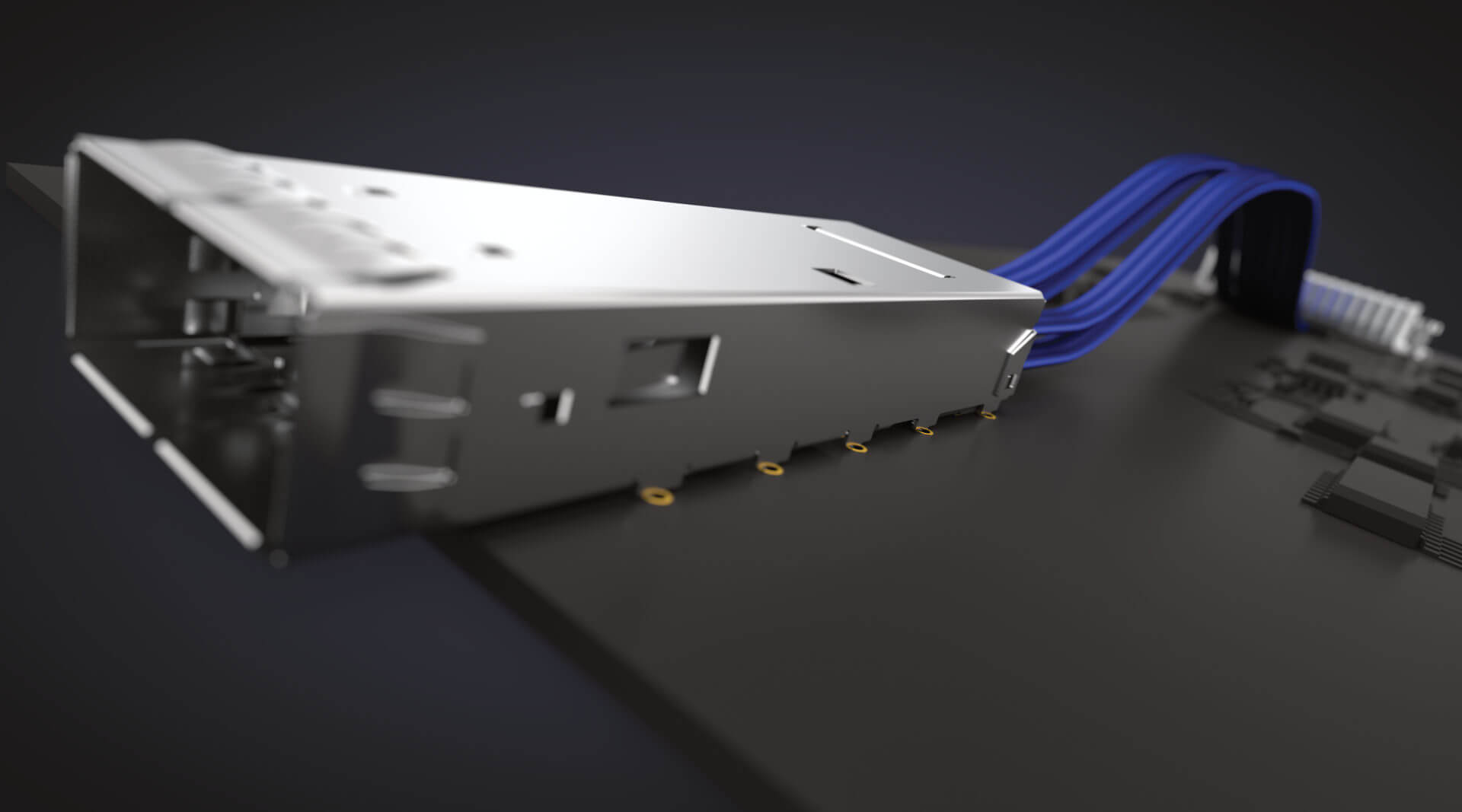

ODI uses Samtec’s FireFly™ Micro Flyover System™ as the physical layer. FireFly™ is the first interconnect system that gives a designer the flexibility of using micro footprint high-performance optical and low-cost copper interconnects interchangeably with the same connector system.

Samtec FireFly™ copper and optical cable systems provide the flexibility to achieve higher data rates to 28 Gbps and/or greater distances, simplifying board design and enhancing performance.

The system’s miniature footprint allows for greater density and closer proximity to the IC, enabling chip-to-chip, board-to-board, on-board and system-to-system connectivity.

For more information about FireFly™, please visit our landing page at www.samtec.com/firefly or download our FireFly™ Application Design Guide. For technical support and design assistance, please contact our optical specialists at [email protected].

Expanding ODI Ecosystems

ODI functionality and flexibility make it a popular interface on commonplace test platforms. From waveform generators and optical bridges to digitizers, signal processors and data recorders, the ODI ecosystem continues to grow.

Here are some examples of the latest solutions now available on the market

- Keysight M8121A 12 GSa/S Arbitrary Waveform Generator

- Keysight M8131A 16/32 GSa/S Digitizer

- Keysight M8132A 640 Gb/s Digital Signal Processor

- Keysight M9411A VXT PXI Vector Transceiver

- Guzik ADP7000 Series 10-bit Digitizer

- Guzik DP7000 Digital Processor

- Guzik DP8000 Fiber Optics Bridge Card

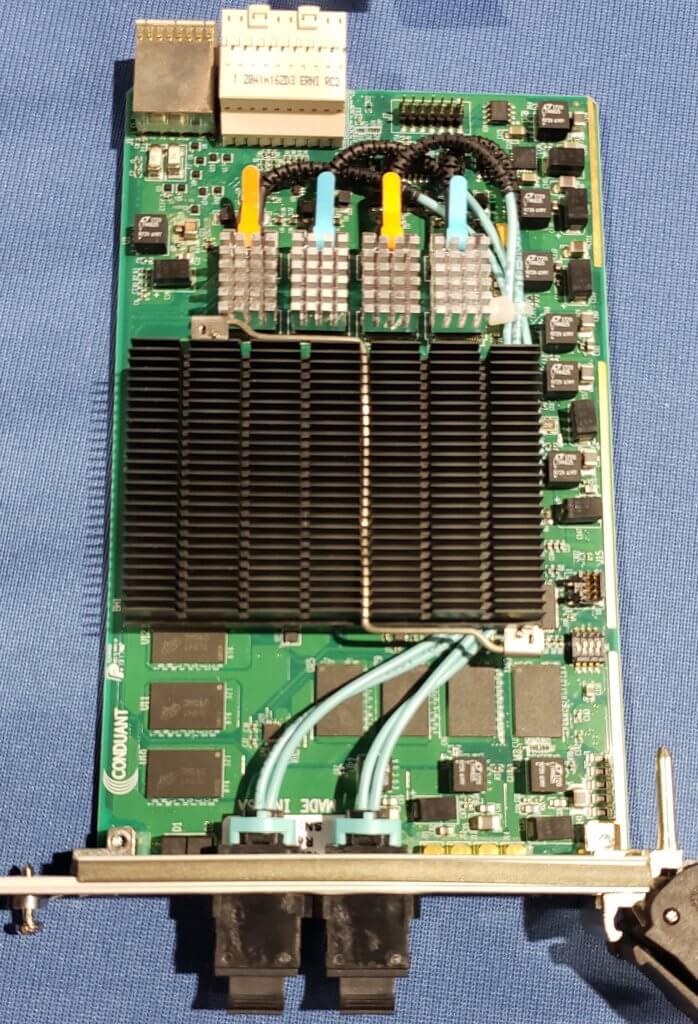

- Conduant StreamStor® High Speed Recording System

Connecting ODI-Compliant Data Recorders to Xilinx Development Boards

High-speed data acquisition (DAQ) systems can be tough to develop. The analog front-end needs to be fine-tuned to a specific application. The digital back end converts and processes the data while combining many channels into a usable data stream.

FPGA development boards, like the Xilinx® Virtex® Ultrascale+ FPGA VCU118 Development Kit, are often used to emulate these applications. They typically offer flexible copper and optical interfaces that can support popular interfaces like ODI.

Longmont, CO-based Conduant recently developed a white paper that details connecting their data recorder to the VCU118. The Conduant StreamStor® supports data recording and playback at rates up to 20 GB/s (160 Gb/s). StreamStor® leverages FireFly™ to connect to a VCU118.

FireFly™ is protocol agnostic, so StreamStor® can connect to almost any Xilinx FPGA development kit using any number of protocols. The Conduant HSS-8324 board provides the optical interface to the Cobra recorder via a 24-fiber MTP/MPO connector.

For more information on this platform, please visit www.conduant.com.

Leave a Reply