A Good Problem?

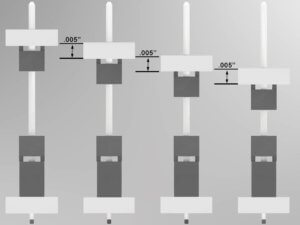

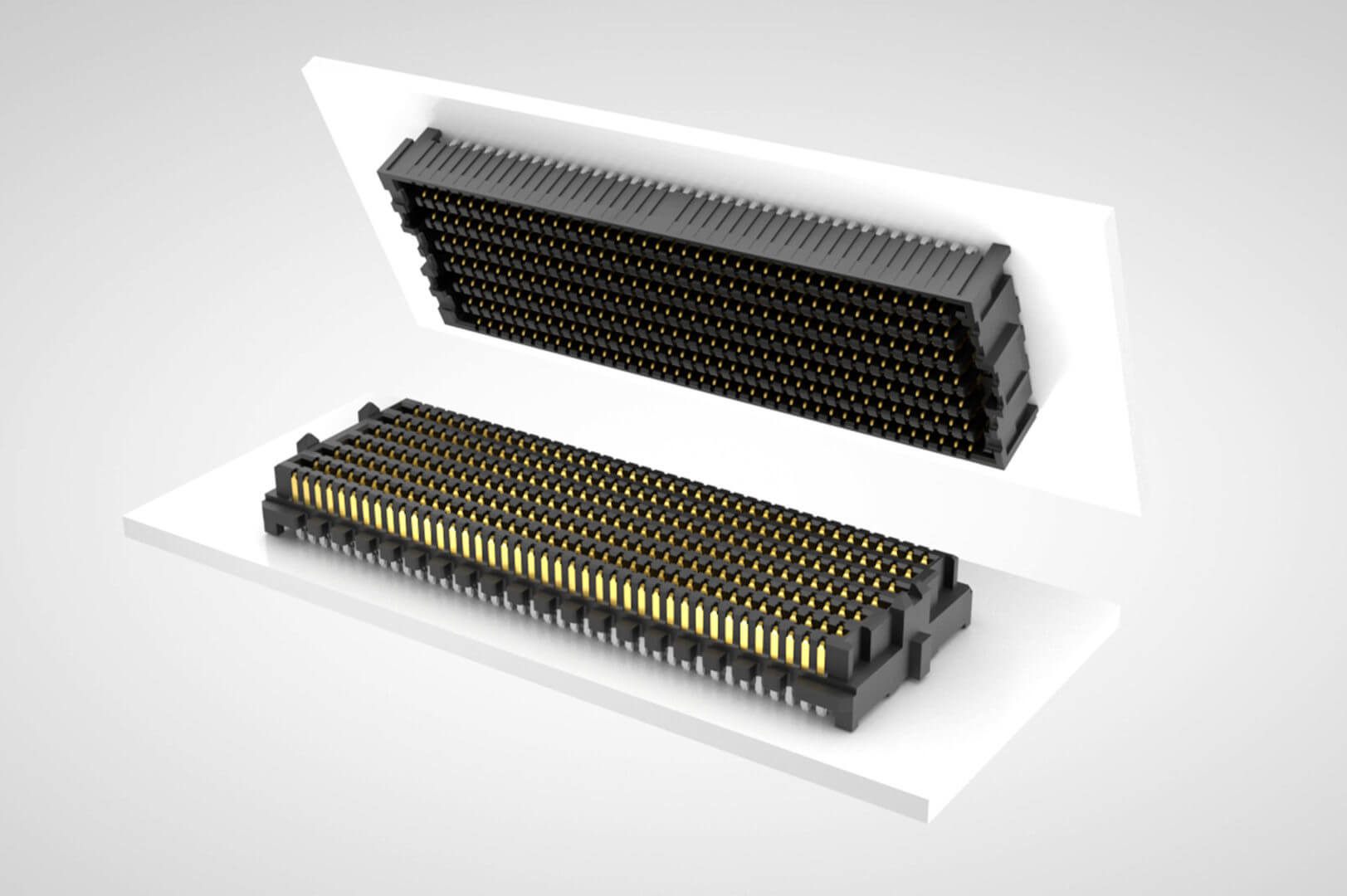

Samtec has more ways to stack two or more boards together than any other connector company. Our manufacturing process allows us to position the plastic body on the terminal pin in increments of .005” (0.13 mm) on standard dual-body stacking connectors and on standard terminal strips (“headers”). Designers can create standard part numbers for very precise, non-industry-standard-board stacking heights.

The good news is we have literally millions of connector combinations, so chances are we can solve your design challenge. The bad news is we have literally millions of connector combinations, and sorting through all of these can be difficult, to say the least.

You Get A Mated Connector Set

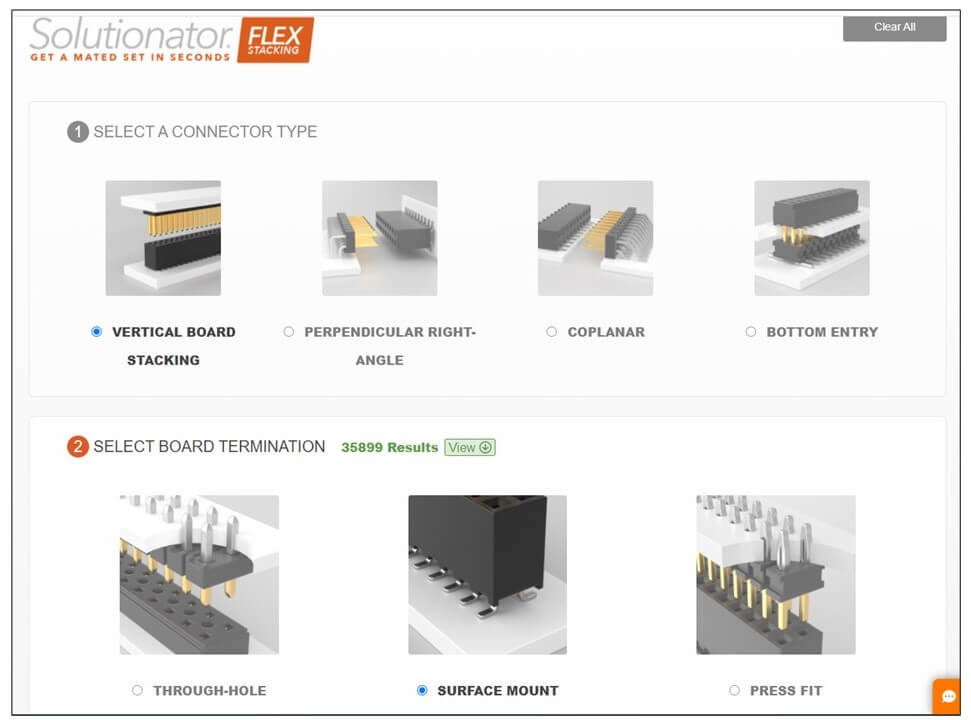

We just introduced a new, improved, and greatly simplified Solutionator® Flex Stacking tool (an online connector board stacking tool) that provides the mated connector set you need for your board stacking design requirements. Let me say that again – the tool gives you complete part numbers of the two mating connectors that meet your design specifications.

Almost every other connector parametric search leads you to one connector, and then you still have to search to find the other half of the mated set. In other words, you have to do at least two searches, and still figure out the stack height of the mating connecting system. And that can be, putting it mildly, a major hassle. With the new Solutionator tool, you can literally locate the best mated connector set for your board stacking application in a matter of seconds.

With most other parametric search tools, you have to begin your search by sorting through countless connector types that you’re not interested in, from a database that includes every connector product in said database. The new Solutionator Flex Stacking tool is for board-stacking connectors only, and the search is simple.

How It Works

You provide specifications for one or more of the following attributes:

Select a connector type; you can choose a vertical (traditional “sandwich”), right angle (90°), coplanar (horizontal), or bottom entry (pass-through) design.

Select the board termination (through-hole, surface mount, or press fit).

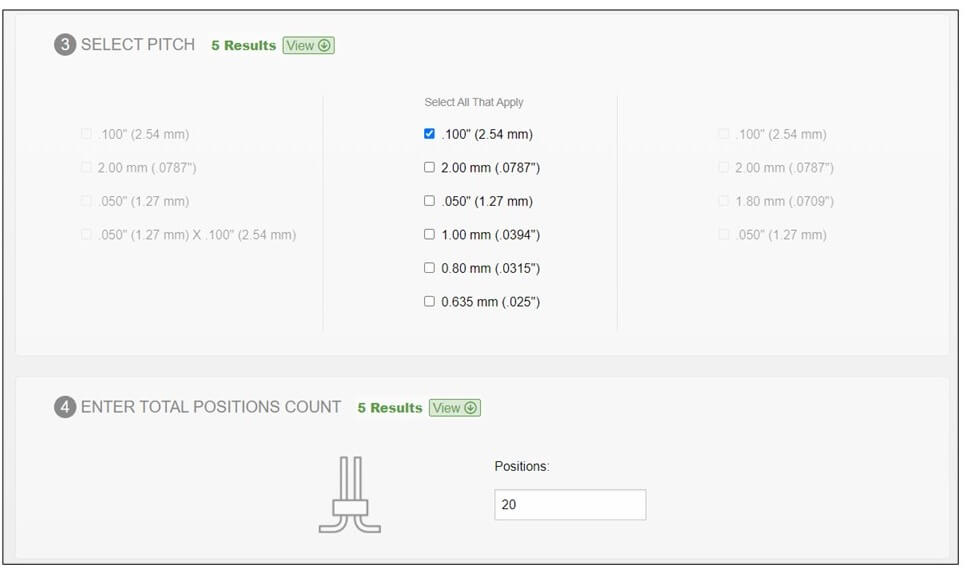

Select the pitch (or centerline) you need. You can choose as many as you like.

Select the number of pins (I/Os) needed for your application.

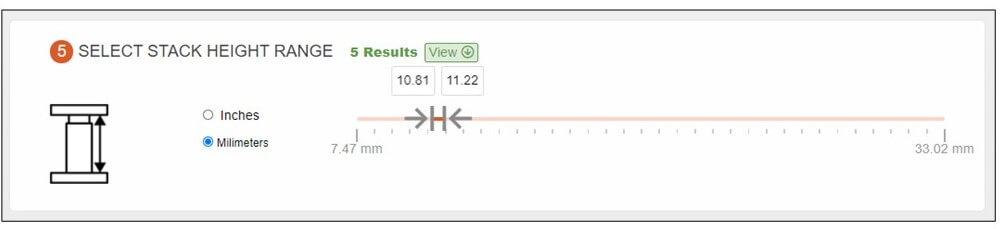

Select the stack height range in inches or millimeters. You can select a range (for example, from 10.81 – 11.22 mm) or a specific stack height (for example, .350”).

BTW, I recommend completing as many search attributes as possible, and being as specific as possible. Like I said before, we have millions of board stacking connector combinations, and the more specific your request, the quicker it is for you to identify the best solution.

Results (Did I Mention You Get A Mated Connector Set?)

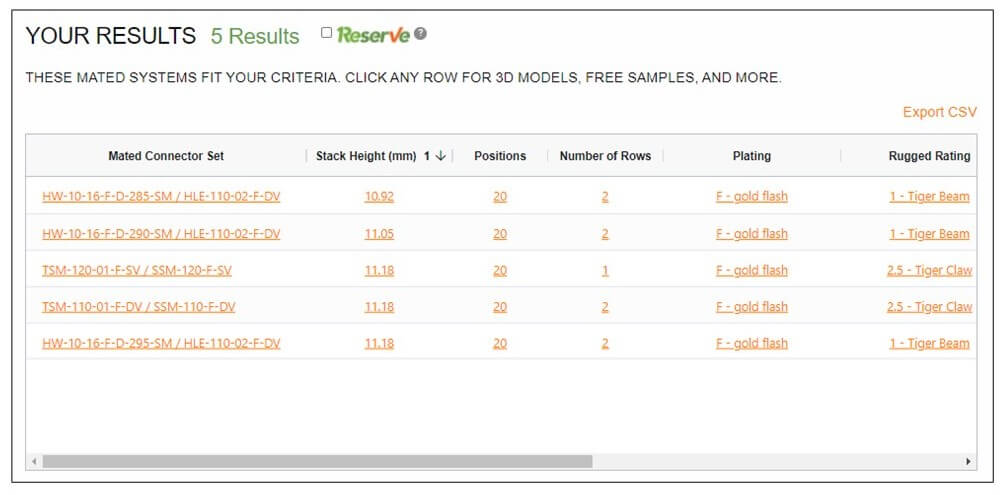

The stacking tool results will list the mated connector sets that meet your design requirements. In the example below, you’ll notice there are five mated connector set options, available in single or double row, and rated by the ruggedness of the contact system.

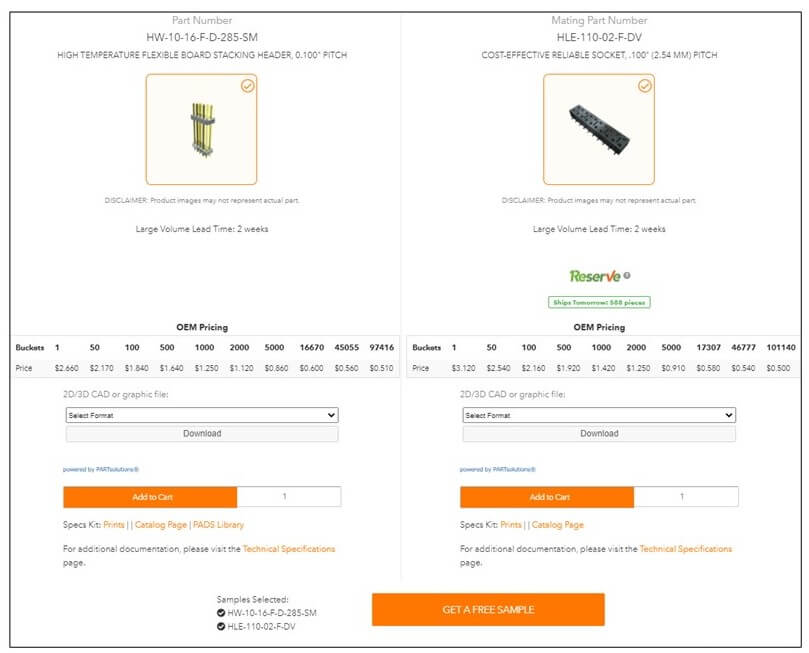

When you select one of the connector sets in the image above, the tool takes you a screen like the one shown below. You can see the full part numbers of the mating connector set, standard book pricing, you can download 2D or 3D models, you have access to prints, catalog pages, and PADS libraries, and you can order free samples.

Notice the HLE socket strip is in the Samtec Reserve™ program. This means a quantity of these connectors can ship tomorrow.

The Solutionator Flex Stacking tool is the first installment of several new Solutionator tools. It covers all of our basic two-piece, pin-and-socket (header and socket strip) products. Coming soon are Solutionators for High-Speed Board-to-Board and Micro Rugged products, among others.

Leave a Reply