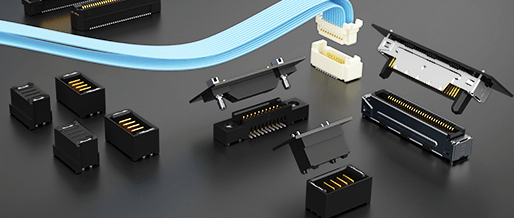

MICRO RUGGED CONNECTORS

Most designers think the smaller the connector, the more fragile and delicate it is. We don’t usually think of micro pitch connectors as being rugged, as being able to handle high mating cycles, or as having robust mechanical strength on the PCB, or with strong retention of mated connector sets.

Samtec has a complete line of micro rugged products that can do all of the above. Our micro rugged products are just that — micro, and rugged. I guess that’s why we call them micro rugged, but I’ll check into that …

The features and options I’m going to tell you about are available on many Samtec connector series, across several different centerlines and sizes, and across many different types of connectors.

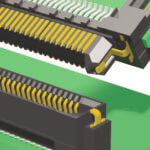

MATING RETENTION

We have numerous elements to help ensure the mated connector set doesn’t come unmated in high shock and vibration applications.

Positive latching systems, which are manually activated, increase unmating forces by up to 200%.

There’s also retention pins which increase unmating force by up to 50% – that’s still a big increase in connector retention.

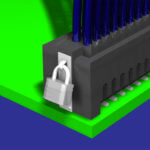

Metal or plastic friction locks are another way to increase retention and withdrawal forces.

Board locks are available on edge card connectors to mechanically lock the connector to the board.

And there’s more extreme options when you’ve got to guarantee the connectors just ain’t gonna come apart …

And we have ejector latches on terminal strips to eject an IDC cable assembly during unamting, and they also help secure the cable assembly in place.

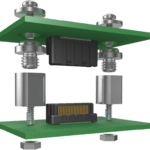

And if you want to make sure the two boards never come apart, like in the event of a nuclear explosion, we have precision stand-offs in board stacking heights from 5 mm to 25 mm.

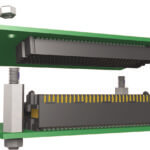

MECHANICAL STRENGTH TO THE PCB

Samtec has several ways to increase the mechanical strength of the connector to the board. IOW, we can help ensure that small connector doesn’t pull off the board during mating and unmating.

Weld tabs, which are soldered to pads on the board, significantly increase the pull and shear force of the connector to the board. Depending on the product line, these are either SMT or through hole.

There’s also screw-downs to secure the connectors to the board and to each other.

We also have jack screws which are used to separate the boards in applications when unmating the connector set may cause damage to the connectors or PCB. This might occur if a connector system has high pin counts, or if the mated connector set has high withdrawal forces.

OTHER RUGGED FEATURES

Other design features that make life easier are guide posts and polarization to make sure mating connector sets are properly aligned when mated.

Alignment pins do just that – they help make sure the connector leads are accurately placed on the solder paste on the boards.

And locking clips, which don’t actually increase the mechanical strength of the connector to the PCB, can be used to hold the connector in place during dual-sided reflow.

There’s more rugged design features than those covered above, but these are the more popular ones.

All of this information, plus our full line of Micro Rugged interconnects, is found in our Micro Rugged Application Design Guide.

Here’s for an overview of our Micro Rugged Products, and our Tiger Eye™ system is our most popular micro rugged family because it’s the best in the industry.