The Loch Ness Monster? There’s that old, grainy picture. Big Foot? I’ve seen the video. UFO’s? Who knows? But micro, rugged industrial connectors? Come on, that’s really hard to believe …

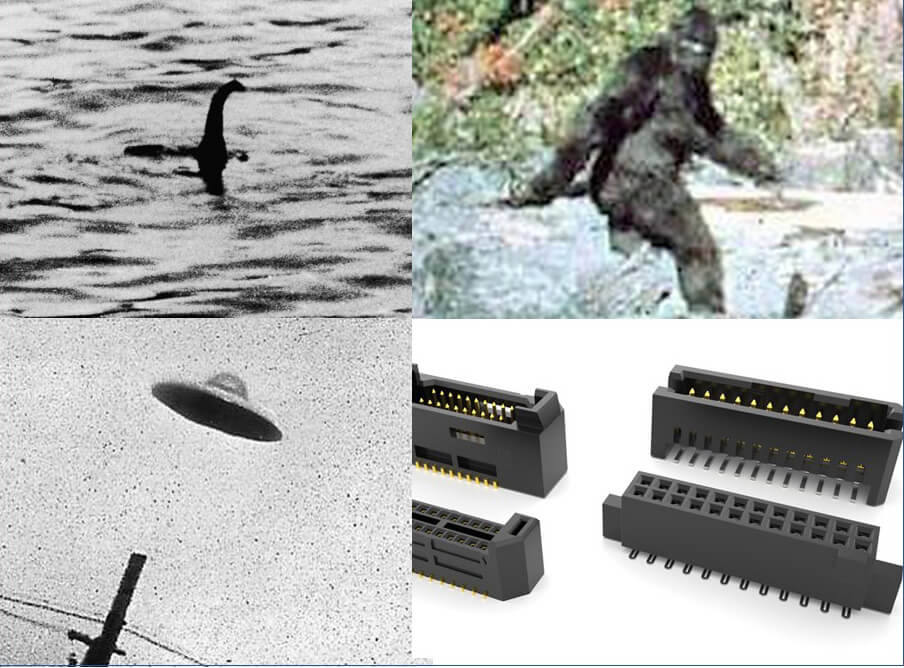

But, industrial electronics is Samtec’s largest selling industry sector, and that’s because Samtec has a full line of micro, rugged industrial connectors. Applications include factory automation, embedded computing, robotics, monitoring, vision systems, measurement, motion and process controls, and security, to name a few

Although the words “micro,” “rugged,” and “interconnects” usually don’t go together, many designers choose Samtec’s Tiger Eye™ interconnect system because it is designed for micro, high-reliability, high-cycle, and rugged applications.

High Reliability, High Cycle

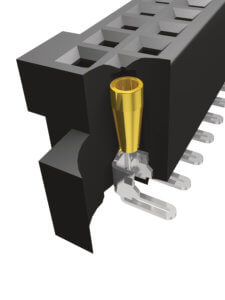

Tiger Eye is a multi-finger, heat-treated, Beryllium Copper (BeCu) contact designed for rugged environments. Once formed and hardened, BeCu will retain its shape under a wide variety of conditions. The superior spring properties of Beryllium Copper make it ideal for high mating cycle applications; it has been tested up to 10,000 mating cycles.

The contact mating surface is on the flat, smooth side of each finger. Smooth surfaces allow more mating cycles because the stress to the plating is minimized. This provides lower contact resistance and longer plating life.

A micro slot on the tail allows solder paste to penetrate the slot, wetting a larger surface area on the lead, providing greater solder joint strength. Connectors with micro tail slots tend to adhere to the wet solder paste prior to reflow better than flat leads.

Tiger Eye contacts are used for board-to-board, IDC, and discrete wire applicatons.

Extended Life Testing

Samtec Extended Life Products (ELP) are popular Samtec interconnects that are tested to much higher mating cycles, and they pass a nasty 10 year Mixed Flowing Gas (MFG) test.

Many EOEMs, especially those in the telecommunications and industrial industries, require their interconnects pass these more stringent tests. The application may simply require many cycles or the product may be exposed to harsh environments.

Designers frequently want this level of performance for their bench testing. The interconnects in their design typically will not see that level of abuse, but the engineers want to make sure their design is robust. In some ways it’s like power or voltage derating; the designer knows that if the connectors are rated at a certain level, then they will work in their less-stringent application.

EDT and MFG

A product must pass two tests to be ELP certified. First is an Extended Durability Test (EDT), which subjects the interconnect system to a higher cycle count. Note EDT is not a test to failure; rather, we test the interconnects to a set number of cycles and rate the connector at that level. The major stresses in EDT are thermal shock and humidity, and connectors are certified if they experience ≤ 15 mΩ LLCR from the initial value. Click here for an example of an Extended Durability Test.

Second, the product must pass a 10 Year Mixed Flowing Gas (MFG) test, based on EIA-364-1000. Click here for an example of a MFG test.

Again, most interconnect applications do not require this level of ruggedness, but verification is available if necessary. If you need to verify product performance to a specific level, Samtec is willing and able to test to your requirements. For more info about specific testing capabilities, or for more info on ELP in general, contact Samtec’s Engineering Support Group.