Each industry has its own standards and requirements that components must meet in order to be considered usable for that industry. There are some tests that are common between industries, such as outgassing, but more often than not there are going to be different requirements that must be met.

For instance, manufacturers within the medical field can be interested in magnetic field testing and magnetic permeability, if their products are used in or near a Magnetic Resonance Imaging (MRI) machine.

An MRI creates an extremely strong magnetic field, normally around 1.5 Tesla, to observe small features in human anatomy, and materials with a potential for magnetism will distort the measurement. As an FYI, a normal household magnet might be around 0.001 Tesla.

What is Magnetic Permeability?

Magnetic Permeability Testing measures a material’s resistance of forming a magnetic field, or the degree of induced magnetism a material experiences under a magnetic field.

Think about magnetic permeability as being similar to conductivity. Some materials can conduct electricity better than others, ie copper, gold, silver, etc; where other materials such as concrete, rubber, and plastic are poor conductors.

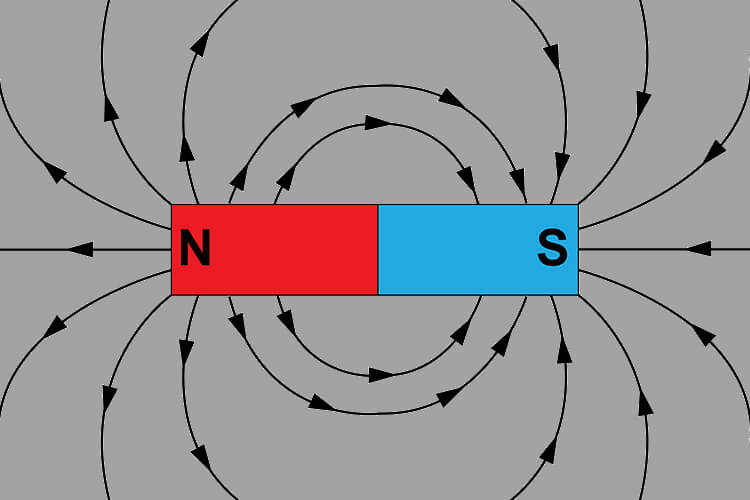

The higher the magnetic permeability a material has the more the material will allow magnetic flux to pass through it. This is represented in a formula by:

B = µH

Where B is the flux density, µ is permeability, and H is the externally applied magnetic force. When µ is = 1 the material is considered to not respond to a magnetic field, and if µ > 1 the material will magnetize in response to the applied magnetic field.

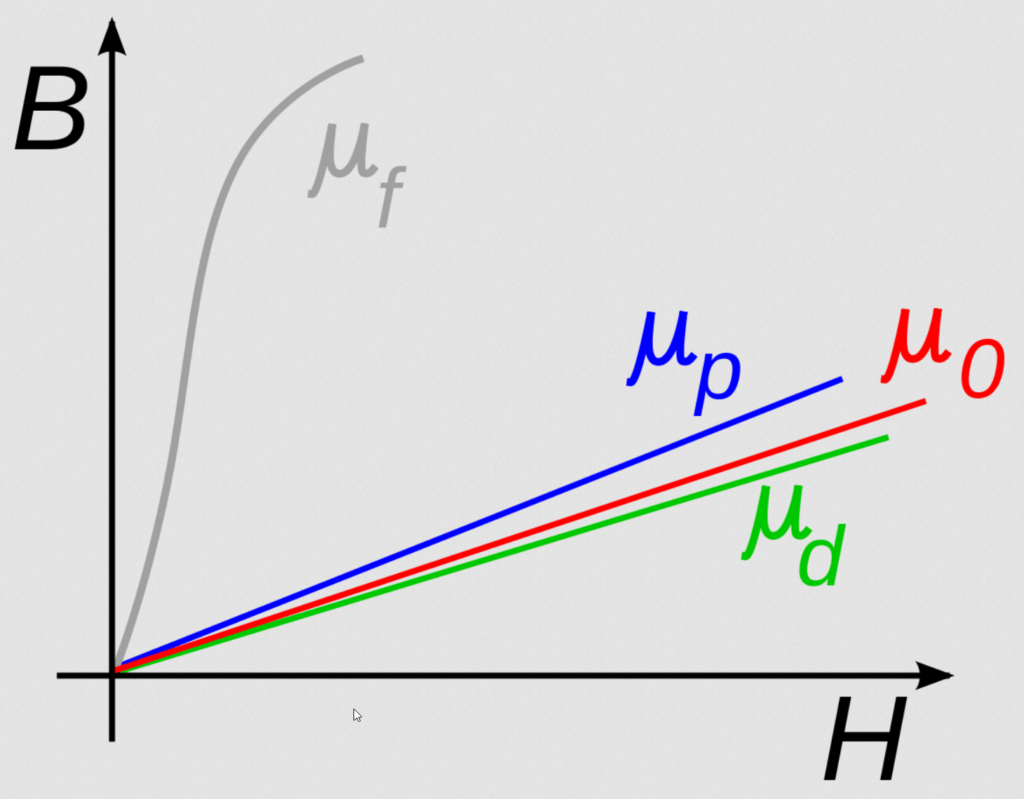

In the graph above, µ0 = 1.25663706 x 10-6 H/m permeability of free space, a vacuum environment. µd is any material that is considered to be diamagnetic, the material is repelled by a magnetic field. Material examples of this would be bismuth and antimony. µp is considered to be a paramagnetic material and will have a µ reading of greater than 1. µf is a material that is ferromagnetic and is attracted to a magnet such as Nickel, Iron, and Cobalt.

Why Perform Magnetic Field Testing?

Magnetic field testing measures the degree by which the presence of a magnetic field will effect a material. This property of being attracted to a magnetic field is known as paramagnetism.

If your products are being used in an environment, such as those around an MRI, it will be important for your customer to know if your product is paramagnetic.

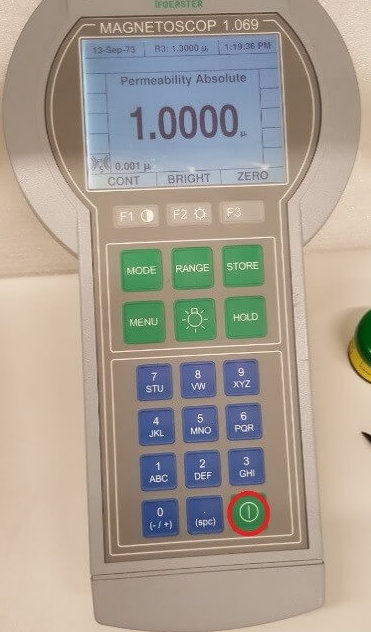

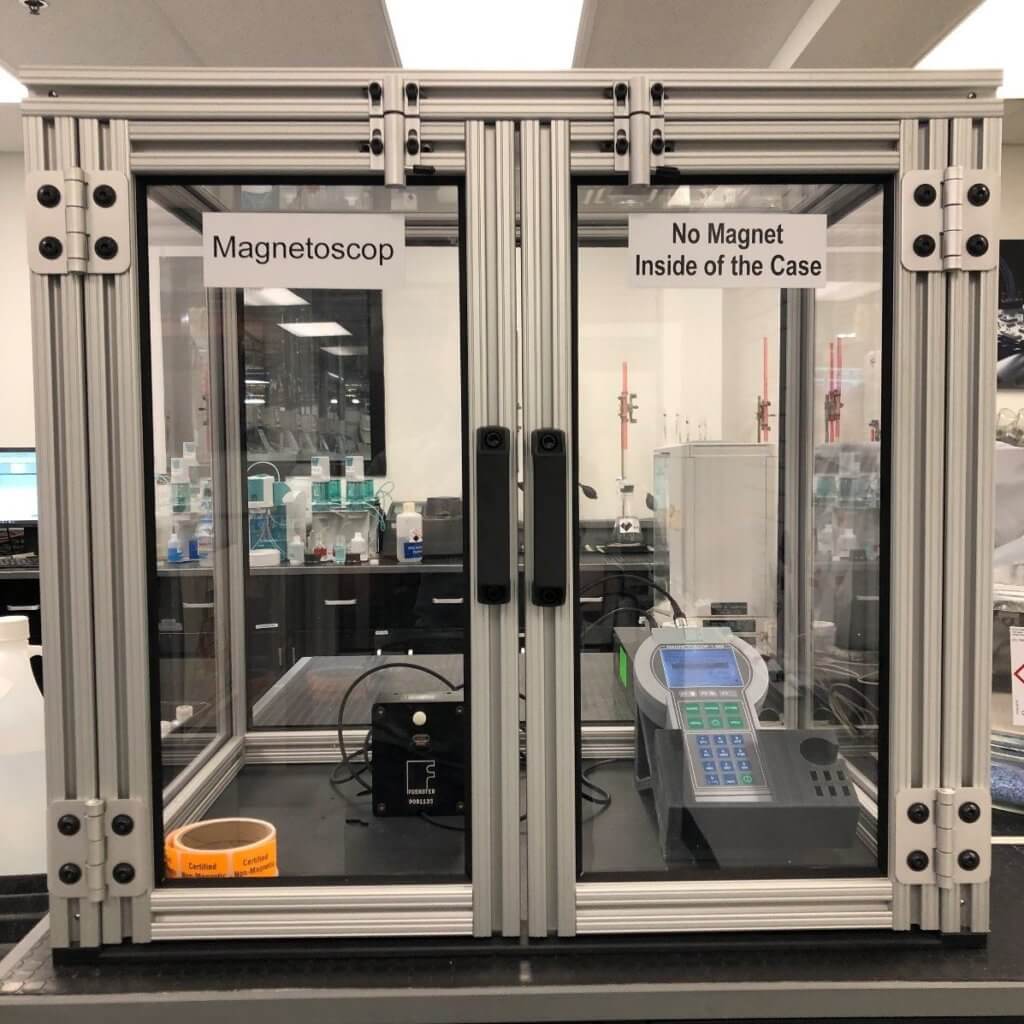

A simple setup, as shown above with the Magnetoscop, can determine how your products will react in that environment. Samtec does test select products to ensure that they can perform in an environment with extreme sensitivities to magnetic fields.

Some popular RF interconnects that can be produced as non magnetic:

- SMA (straight, right angle, edge mount)

- SMB (right angle)

- MMCX (straight, right angle, edge mount, high vibration)

- MCX (straight, right angle, edge mount)

- SMP (straight, edge mount, bullet adaptors)

- RF 174 (SMA, SMB, MMCX, MCX)

- RF 178 (SMA, SMB, MMCX, MCX)

- RF 316 (SMA, SMB, MMCX, MCX)

If you have questions concerning Magnetic Field Testing then please contact [email protected] for more information.

For the Fun of It

If you have made it this far, then here is fun/interesting video of some people “experimenting” with an old MRI machine. Some of the forces shown in this video are pretty incredible, and stress the importance of keeping ferrous metals away from an MRI.

Leave a Reply