If you are involved with ISO 9001 then you probably know that “continuous improvement” is the name of the game. After all Rome wasn’t built in a day, and neither was Samtec’s newly updated Outgassing Guide.

Our first version of the Outgassing Flyer was focused on the information that we had at the time, but being Samtec, we didn’t stop there, and that is the topic of today’s blog.

Third Party Testing

In the past, industry wide, manufacturers have relied on the outgas testing that NASA provides on their website. Their website has been a wealth of knowledge for years, but there are times when you need information about a material that they have not tested.

That is where third party testing comes in, and Samtec has tested many of the materials found in the products associated with Severe Environment Testing (SET).

Since SET is geared towards extreme conditions, it is only fitting that the information on outgassing be available as well.

If you are not familiar with outgassing testing, how it is done, and what it measures, then make sure to check out the last blog where we go into all of this in detail.

How Did the Products Perform?

To simply put it, they passed. This clearly comes as good news as you don’t want to have a connector that outgasses operating in a high altitude and / or sealed environment.

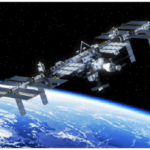

Below is a table from our updated Outgassing Guide that shows the materials that have been tested, and their results. Please keep in mind that these are mainly from products associated with SET, but there are others as well. It should also be noted that Samtec has connectors made with other polymers as well.

As a reminder, the parts are tested by taking the weight of the sample before and after the experiment. The polymer passes if the total mass lost (TML) and the collected volatile condensible materials (CVCM) are below 1.0% and 0.10% respectively.

As seen in the table above, all of the series listed are considered to be a low outgassing series.

If you have any further questions concerning a product for your extreme environment application, then please contact [email protected].

Leave a Reply