You might remember the last blog on Immersion Cooling where we introduced Samtec’s new landing page for Immersion Cooling. The test results are in, and they look good.

Samtec has partnered with Engineered Fluids to run a series of qualification tests on several of our product series. This was done to see how well they perform, and to prove the connectors function as they should in that environment.

What Was Tested?

So far, we have the test results for our popular SEARAYTM series and EXTreme Ten60Power™ series. Several other series are in queue, including Micro Rugged Connectors, Power Connectors, and High Density Arrays, to be tested.

For each series, the tests are being conducted in open air as a control group, and in ElectroCool EC-130. The tests conducted include:

- Mating/Unmating/Durability (Humidity, LLCR, Thermal Age and Thermal Shock)

- Insulation Resistance/Dielectric Withstanding Voltage (IR/DWV)

- Current Carrying Capacity (CCC)

- Current Cycling (CC)

What were the results?

Looking at the EXTreme Ten60Power™ series, we see very favorable results from the connectors operating in ElectroCool EC-130. As you would expect, the connectors can produce better electrical results.

This is due to the liquid dielectric’s ability to disperse heat more efficiently than air, and having a dielectric constant of 2.104 vs 1.00059 for air.

Looking at a couple of the tests below, we can see the extra performance gained by operating in an immersion cooled environment.

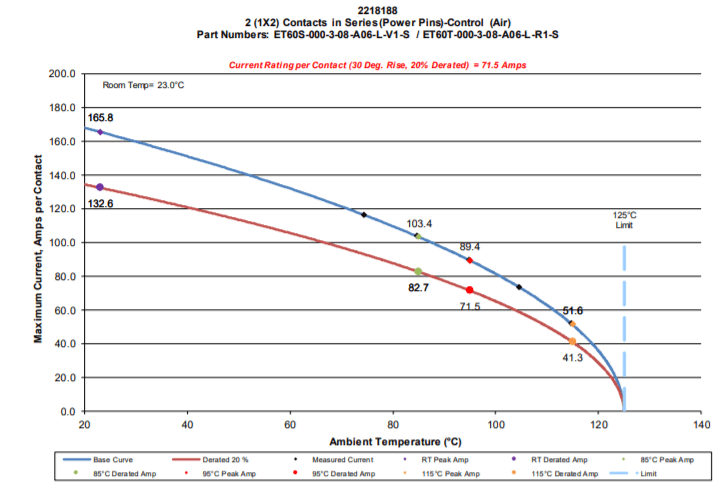

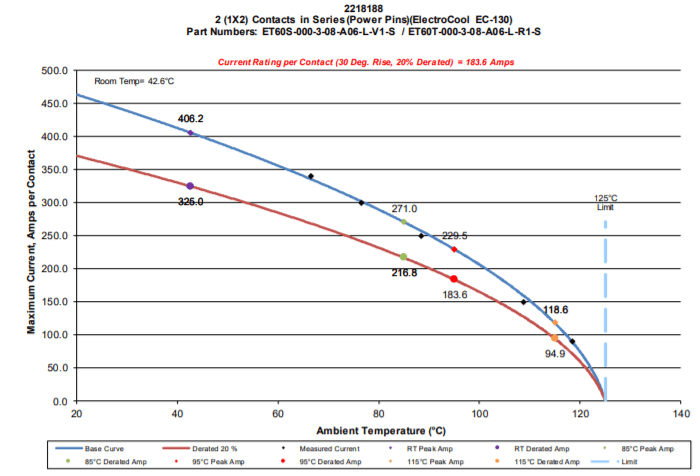

Current Carrying Capacity

Current Carrying Capacity is used to establish the maximum current carrying capacity vs ambient temperature without exceeding the temperature limitations of the materials in the connector set.

For the EXTreme Ten60Power™ series we are going to look at the power pin capabilities for two power contacts powered in air vs EC-130. Below are the results of all of the CCC tests.

Looking at the two power contacts in air we can get 71.5 A per contact vs 183.6 A per contact in EC-130.

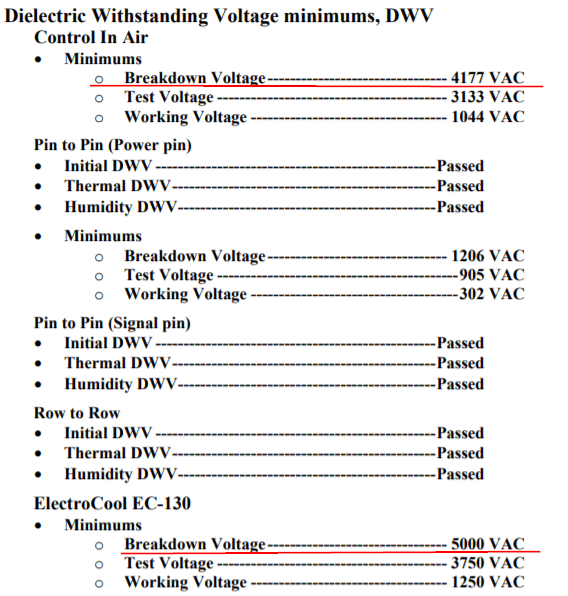

Dielectric Withstanding Voltage (DWV)

Dielectric Withstanding Voltage (DWV) uses momentary over potentials caused from surges or switching and establishes the proper operation at test voltage.

Looking at the EXTreme Ten60Power™ series we see the DWV Breakdown Voltage in air is 4177 VAC for the power pins, and 5000 VAC in EC-130.

The rest of the test results can be seen on the test report here.

As Samtec continues through the testing, the results will be published on the Immersion Cooling landing page here. For more information about the test specifics or any other questions regarding immersion cooling, please contact [email protected].

Leave a Reply