The aerospace industry has had a tough time over the last 12 months. Not only has the commercial aviation market suffered severely from the effects of the COVID-19 pandemic, but the industry has not been able to showcase its latest developments.

The signs of a recovery are beginning to show. The SUN ‘n FUN Aerospace Expo took place in Florida during April, providing enthusiasts and professionals with their first look at new aviation technology for nearly a year. On show was everything from basic training aircraft to the latest military technology. However, one of the most striking aspects of aviation today is the sophistication of modern avionics.

The name avionics is a contraction of the words aviation and electronics and is used to describe almost every aspect of these systems used in aircraft, from the simplest to the most complex.

There was a time, not too long ago, that high-performance avionics systems were purely the preserve of military pilots. The development of 4th generation combat aircraft during the 1970s, such as the F-16 Fighting Falcon and the Mirage 2000, represented the lessons learnt from the types that went before them. The design philosophy changed from one of single-role specialist aircraft to multi-role flexibility. At the same time, technology was allowing the creation of controls for the pilot that would help enable this change by reducing their workload and increasing their efficiency.

aircraft that revolutionized the design of avionics

From Steamship to Rocket Ship

The adoption of these aircraft introduced us to a raft of new TLAs (three-letter acronyms), from the HUD (Head Up Display) to the MFD (Multi-Function Display) and FBW (Fly by Wire) controls. With these innovations, the pilot’s working environment evolved from a huge array of conventional dials to a small number of configurable displays, presenting information with simple, easy-to-read symbology. Suddenly, the cockpit of military aircraft came to resemble a computer arcade rather than the engine room of a steamship, and the increase in their capability brought about by this revolution has been proven time and again.

As the technology matured, the commercial aerospace industry was able to employ similar systems. The flight deck of the latest generation of airliners would appear almost empty to the pilots who flew in the 60s. Modern commercial aircraft are even using HUD technology to improve pilots’ situational awareness.

This had an almost immediate effect on a whole range of other technologies, including connectors. Information that had previously been presented using a mechanical gauge was being provided as part of an electronic display, and so the volume and speed of electronic signals required for them to function grew exponentially. It is from this period that we can trace the origins of some of the most popular connectors used in the military and aerospace arena, as they were designed specifically to cope with these new digital systems.

It has taken many years, but this technology has become more accessible to the rest of the industry. Just as modern family cars benefit from technology developed for Formula 1 or Indy cars, modern general aviation is now using the systems developed for combat and commercial aircraft.

The cockpit of modern aircraft, even the humblest propeller-powered training airplane, is a showroom for the latest avionic technology. In place of traditional mechanical gauges, many aircraft boast just one or two oversized screens on which can be displayed a wealth of flight, navigation, communication and safety information. Fully configurable, they are designed to provide pilots with all of the information they need in a single, unified picture that reduces their workload and improves safety.

Small Size but Huge Functionality

The challenge for designers of these new avionic systems is to incorporate all of the functionality demanded by modern pilots in packages that can be installed in small aircraft. At the same time, it is imperative that safety is not compromised, and so these systems need to provide superior reliability. Finally, this equipment must function in the demanding environment of the aviation industry, subjected to shock and vibration associated with a lifetime of flight operations.

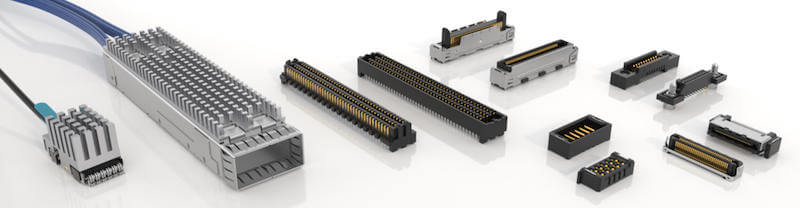

The connectors employed within modern avionics must be capable of transmitting high-speed data whilst providing superior reliability demanded by the tough conditions found in aviation. While traditional military-specification connectors are sometimes useful, many of them are too bulky and cumbersome to be designed into the latest devices.

Fiber optics have also started to play a part in the avionics world. The data rates needed for modern avionics make the high performance of fiber communications an attractive solution. In addition, the small size and low mass of optical systems are both features that are hugely attractive in the aviation industry where weight is the enemy.

Samtec provides connector solutions that are ideally suited to the needs of the modern avionic designer. From high-density, PCB-mounted arrays to high-speed precision RF connectors and cutting-edge fiber optics, the Samtec product range supports a huge variety of avionic applications. Combined with the Severe Environment Testing (SET) and Extended Life Product initiatives, Samtec can deliver confidence and reliability as well as performance and service.

Take a look at our new military and aerospace applications page to learn more about the Samtec products that are supporting these vital industry sectors.

It is interesting to learn how modern general aviation is using systems developed for commercial aircraft. My sister is fascinated by aviation in general and is thinking of making it part of her career. I’ll share this info with her as she looks up more information regarding avionic systems.