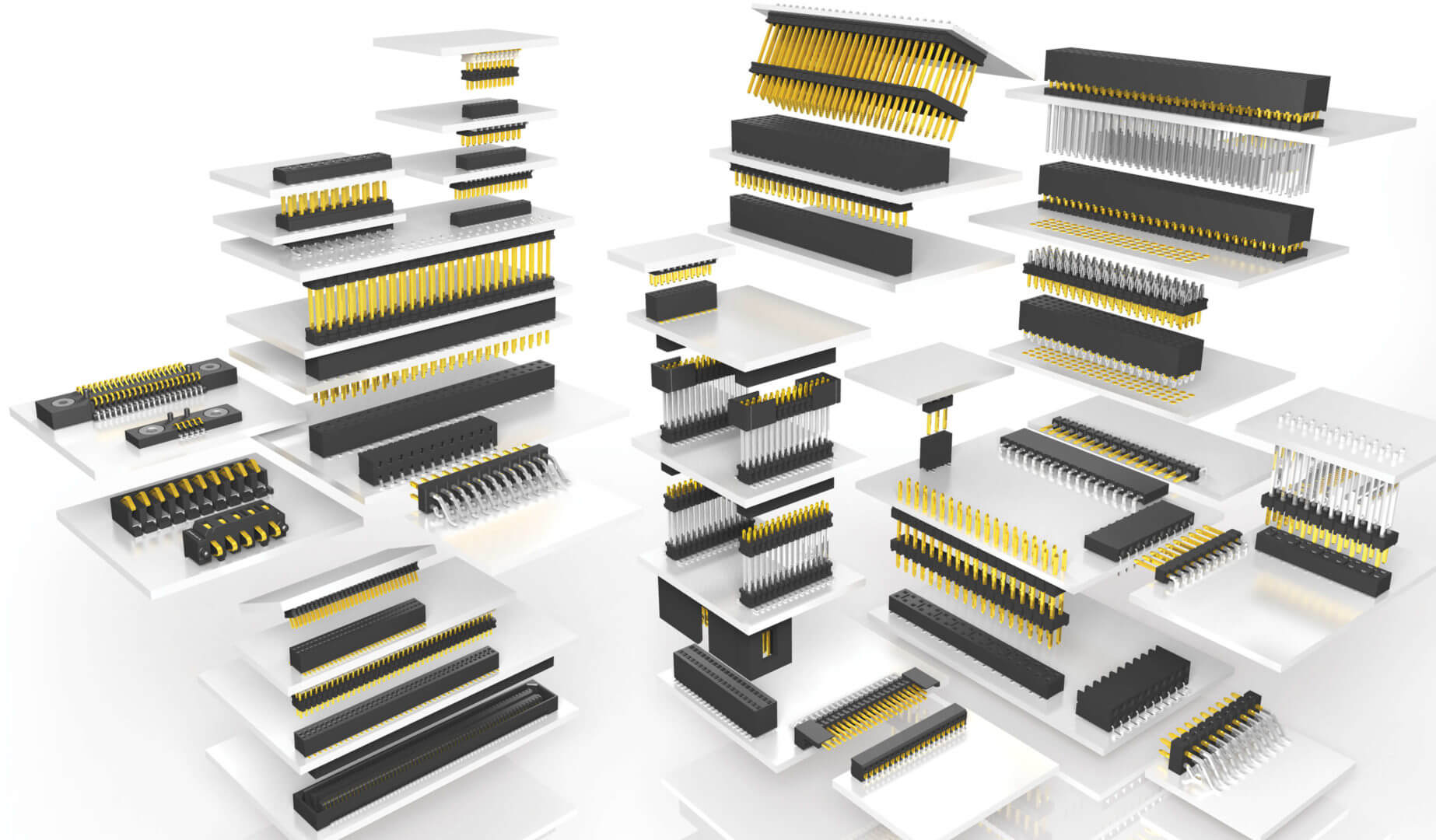

Many Samtec blogs discuss bleeding edge technologies, new products, or provide guidelines and tips on optimizing system performance. Having said that, our biggest selling product line is standard pitch (2.54, 2.00, 1.27 mm), two-piece board-to-board interconnects. These are not as sexy as using an ultra-high-density interconnect with PAM4 to achieve 56 Gbps serial channels, but they look mighty appealing if your job is to identify and design-in reliable board-to-board interconnect systems.

FLEX STACKING

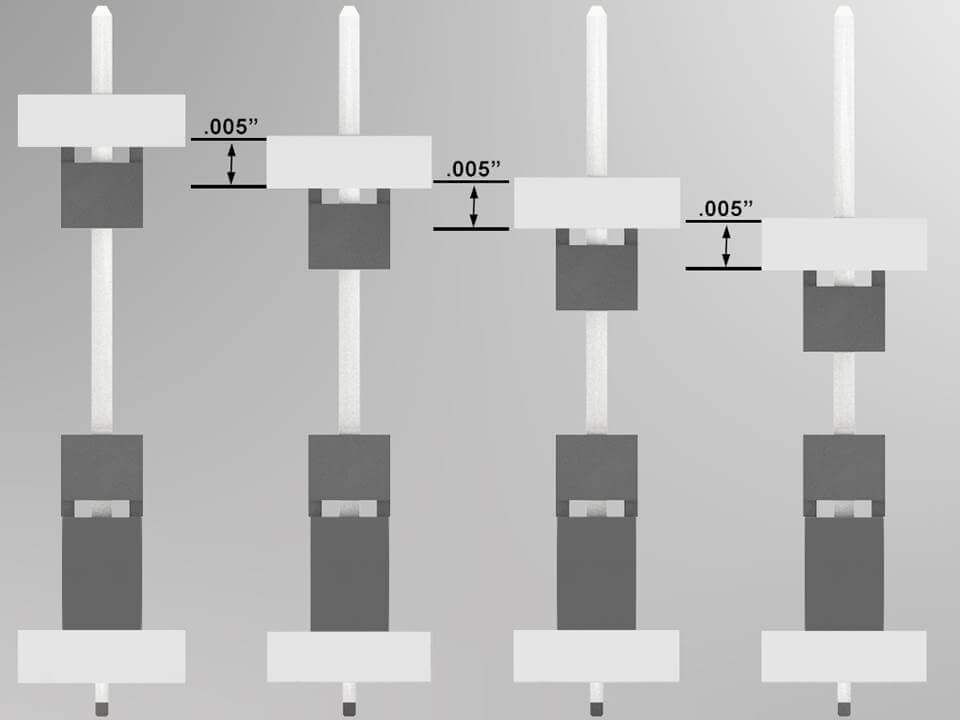

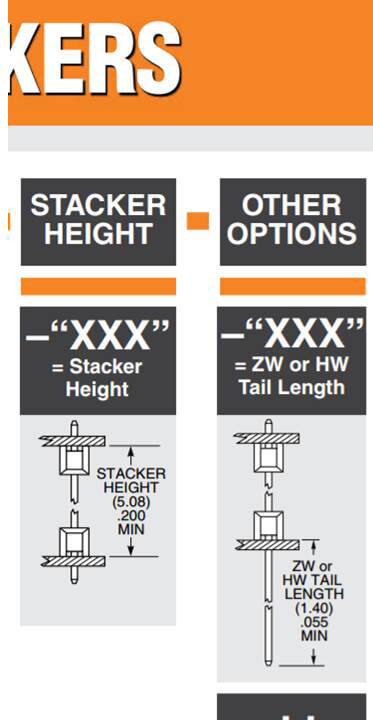

Samtec has more ways to connect two or more boards than any other interconnect provider. One really cool capability is what we call “Flex Stack.” Flex Stack is the ability to move the plastic insulator (body) up and down the terminal pin in increments of .005″ (0.127 mm) on header strips and dual-body stackers. If you need a .360″ stack height, we’ve got it. Ditto .365,” .370,” .375,” and so on.

You specify the post height and or stacking height — the distance between the two plastic bodies — in the standard Samtec part number. See the “-XXX” to the right.

This allows designers to order a custom stack height connector system with:

- a standard part number

- no minimum order size

- no long lead times

- and no tooling or NRE charges.

The Flex Stacking capability is available on .200″, .156″, .100,” 2 mm, .050″, .050″ x .100″, 1 mm, and 0.80 mm pitch terminal strips.

PASS-THROUGH BOARD STACKING

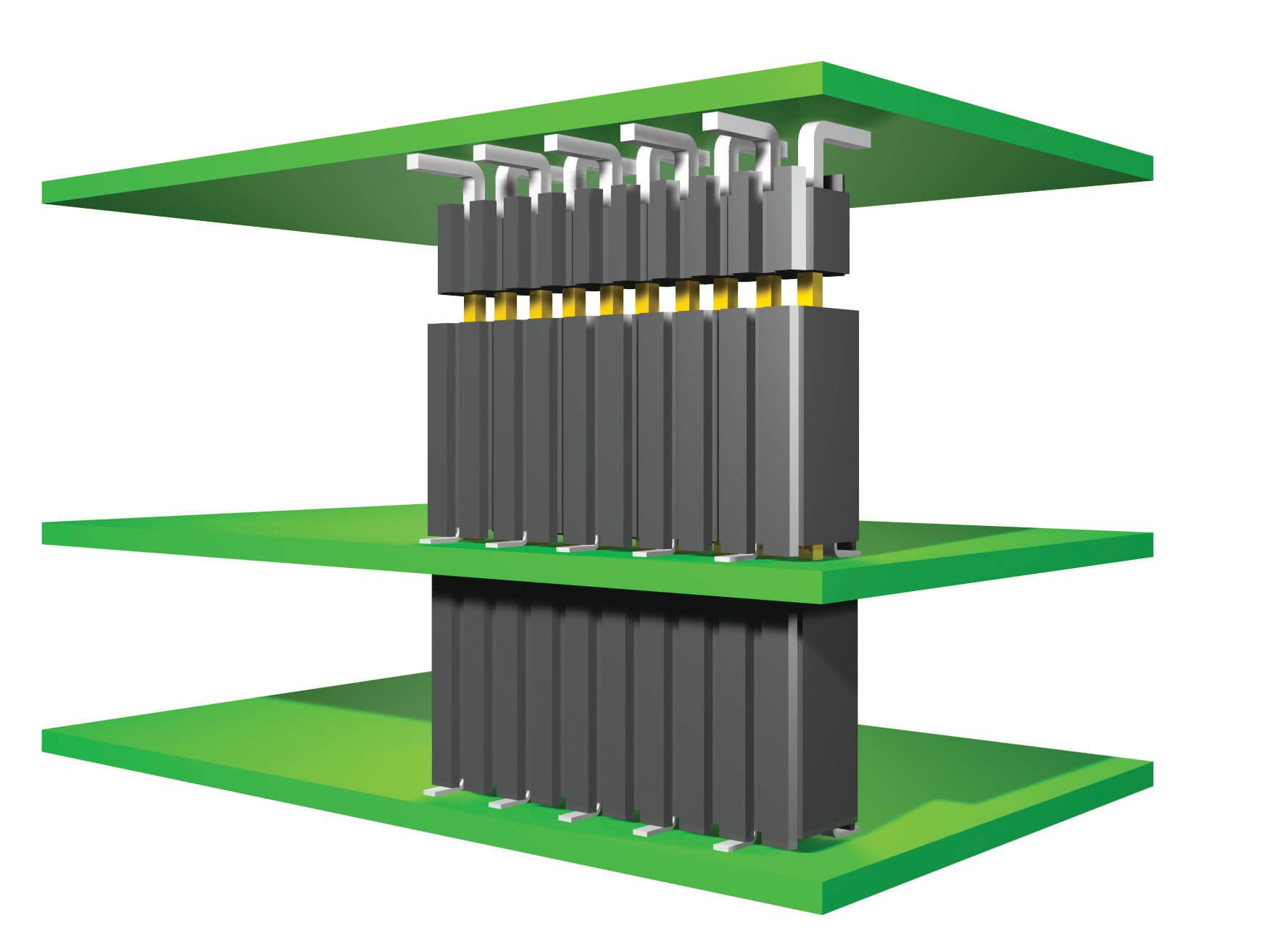

In addition to the the Flex Stack capability on terminal strips, a variety of contact systems available in Samtec socket strips also gives designers the flexibility to do some pretty creative board stacking.

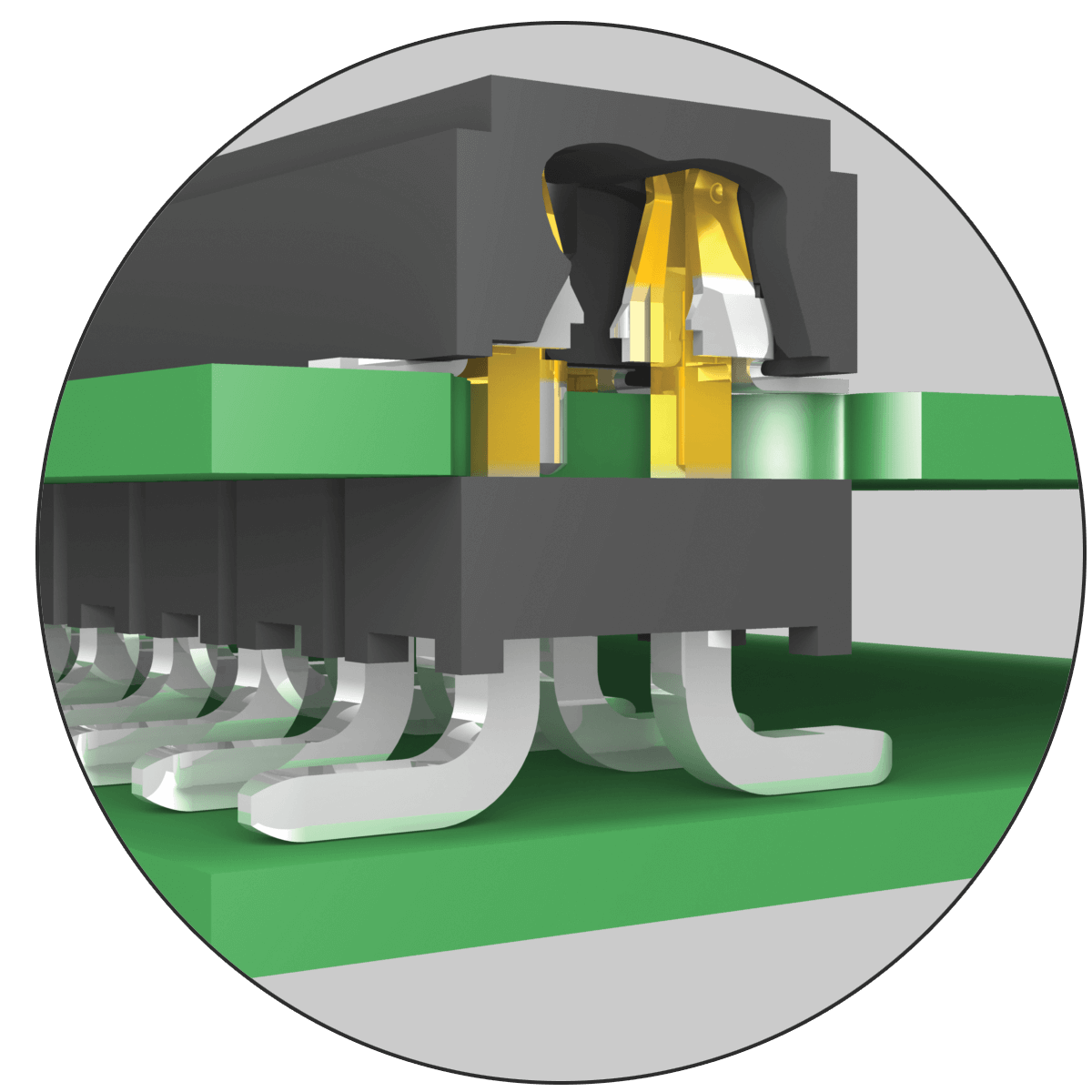

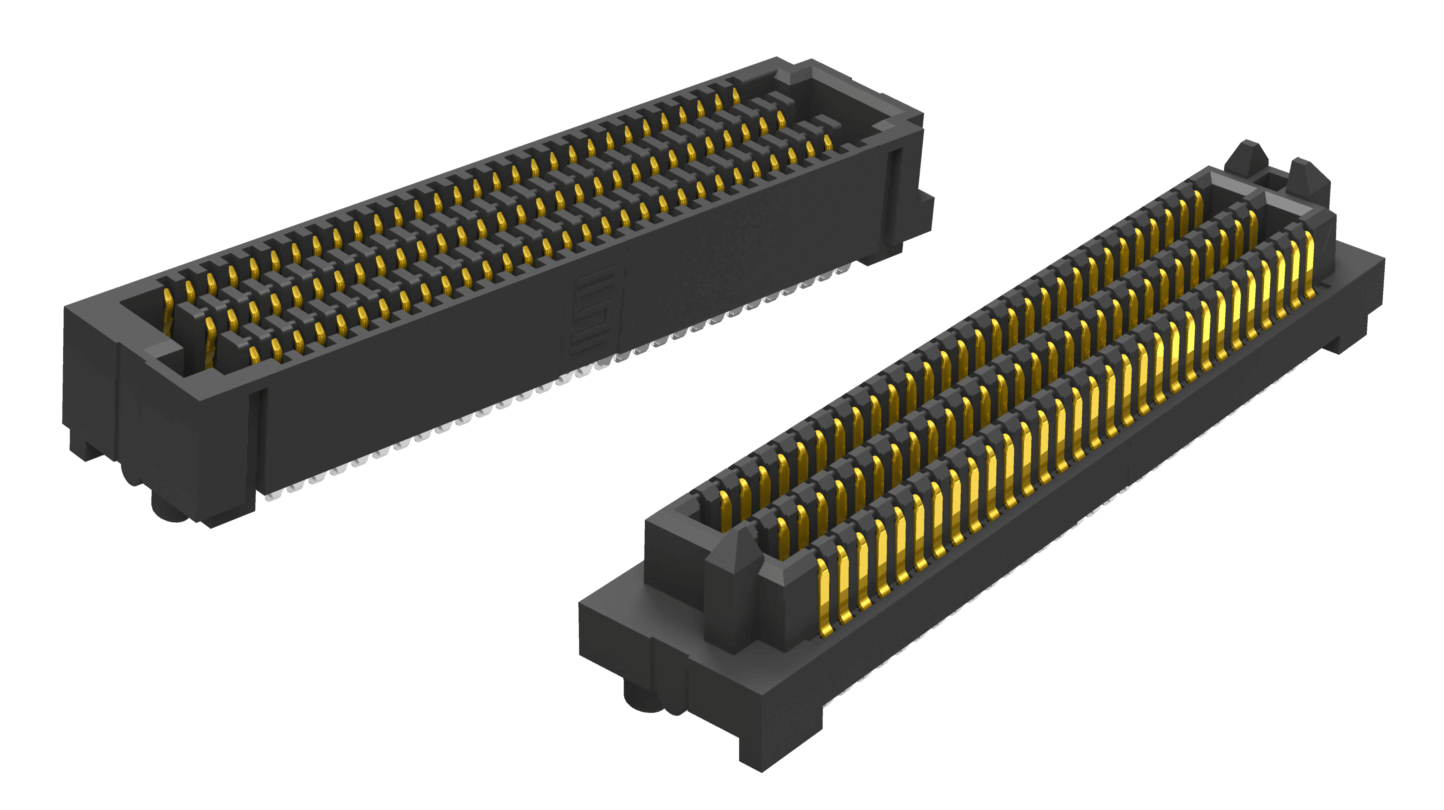

For example, Samtec’s Tiger Claw™ contact is a low-profile, dual-wipe, pass-through contact. The Tiger Claw contact is available in 1.00, 1.27, 2.00, and 2.54 mm pitch socket strips. The profile of the SMT version is usually 2.29 mm (.090”). But more importantly for today’s discussion, Tiger Claw is a pass-through contact, meaning the terminal strip pin can pass through the bottom and/or top of the socket strip.

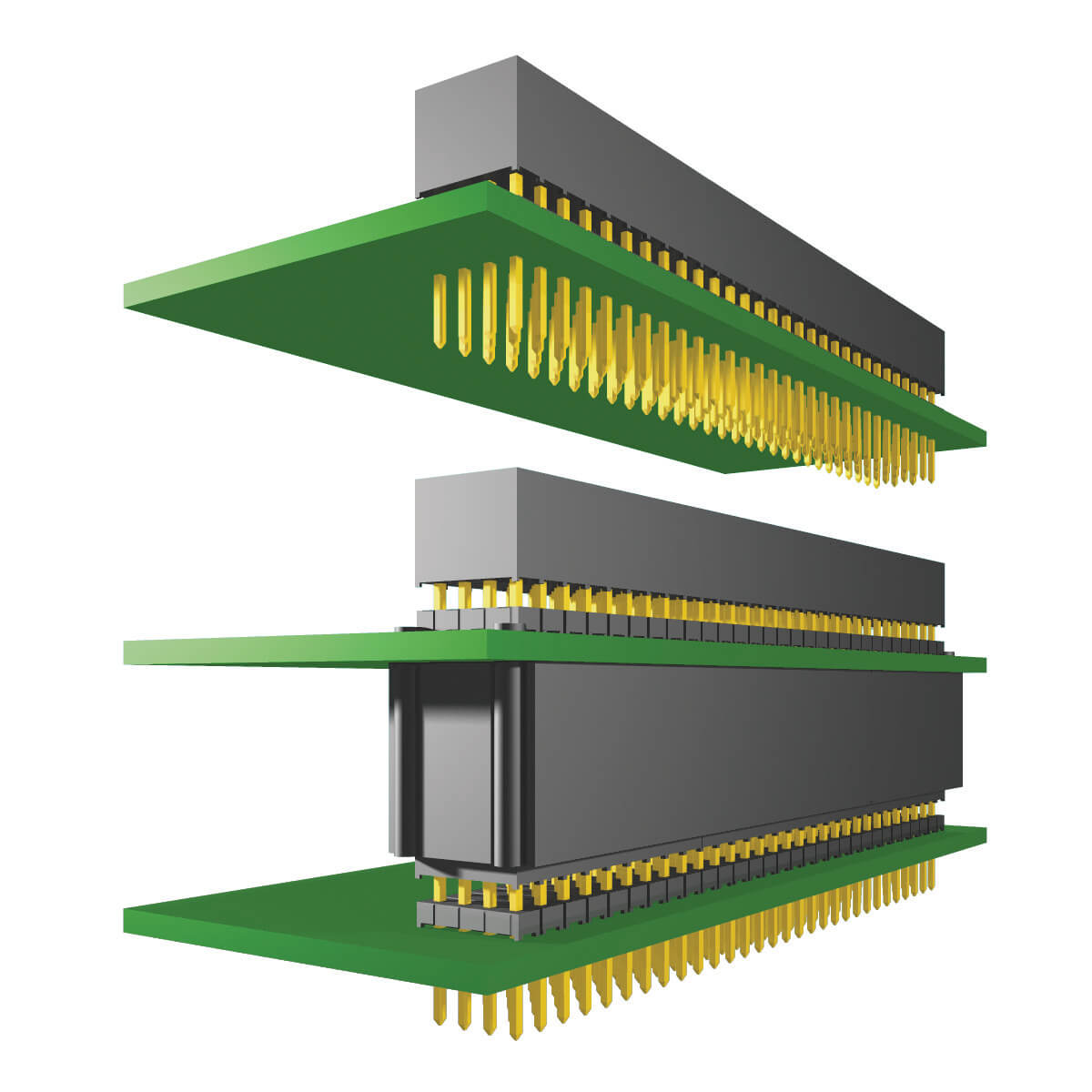

Pass-through sockets give designers the ability to connect three boards. A common example is shown in the illustration to the right. The terminal strip, with longer pins, is on the top pcb. These pins pass through the Tiger Claw contacts in the socket, and through non-plated through-holes in the middle pcb. These same terminal pins then mate with a second socket on the bottom (third) board.

Pass-through sockets also allow bottom-entry, pass-through applications, where the terminal strip pin (on the bottom pcb) passes up through the bottom of the top pcb and into the contact. This is used for low profile board stacking, or if the application requires certain components to be on the top side of the pcb.

For that matter, another common application is self-nesting systems, where the tails of one socket pass through the pcb and plug into another socket, which plug into another socket, which can plug into another socket, and so-on. PC/104 is a common example of this design.

By they way, Samtec has literally millions of ways to connect two or more pcbs. Check out the online Solutionator tool. It makes it very easy to find the best mated socket and terminal set, based on your design requirements.

Below is a list of some of our more popular Flex Stack products. But there’s a lot more than that. If you want to ask about a specific application, contact the Application Support Group.