Modern vehicles, whether family cars or heavy transportation, are growing in sophistication. Manufacturers are constantly developing new technologies for safety and convenience, from regenerative braking to the very latest head-up displays.

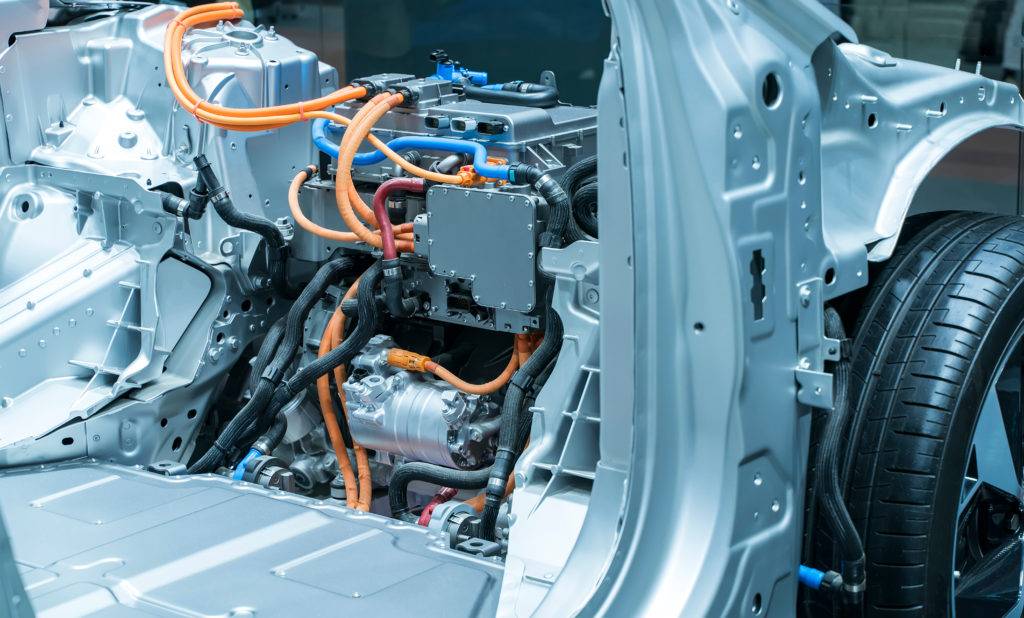

With the huge growth in the demand for electric vehicles and the prospect of autonomous cars closer than ever, the architecture of electronic systems within cars is under pressure.

Electronic Control Units

For many years, manufacturers introduced new features by simply adding extra equipment into the car and providing the cabling to connect it to the rest of the systems. Each feature is controlled by an ECU (electronic control unit), which is a small device that is responsible for controlling that specific function.

However, the advances in modern car design mean that there can be between 100 and 150 ECUs in every car. The size of each ECU and the associated cabling they require means that manufacturers are finding it increasingly difficult to add new features by simply adding yet another ECU.

Not only are manufacturers running out of space, but they are also faced with integrating the latest features which are resulting in a greatly increased flow of data around the vehicle. The current architecture, using single-function ECUs and long cable runs to a central computer, will not be able to cope with the increasing demands placed upon it.

As we have seen in our previous articles about C-V2X technology and the latest vision systems, data will be of huge importance in future car design. Vehicles will collect information about their own function and the environment around them, and share this data with other road users. However, safety systems will need to act with the lowest possible latency to ensure that the vehicle reacts as quickly as possible to potential hazards.

Embedded Compute Modules

Conventional ECUs do not possess the computing power to provide the rapid processing capability needed for these systems, and so we will see increasing use of embedded computing modules in automotive design. These modules will be robust, single-board computers, capable of processing the volume of data that future automotive systems will generate.

By processing data close to the components they control, embedded compute modules will help to reduce the network load, and proximity will result in lower latencies while collecting data to accurately identify and respond to the environment.

Unlike the conventional ECUs that they will replace, embedded compute modules will require high-speed infrastructure around them to reach their full potential. Data speeds in the systems of the future will mean that conventional automotive connectors will be unable to support the latest technology. Samtec connectors are capable of high speed, and are tested using Samtec’s own in-house Severe Environment Testing program. This program tests connectors far beyond conventional commercial standards, providing peace of mind to the engineer who is designing for the next generation of vehicles.

Samtec manufactures a range of connectors and cabling systems for embedded compute modules, along with a wide range of other automotive applications, and is certified to IATF 16949, ISO 14001 and ISO 9001,. Visit the automotive applications page on Samtec.com to learn more about how high-speed and high-reliability are coming together in Samtec’s automotive product range.

Leave a Reply